Introduction

This website provides the most comprehensive information about test chambers available online.

Here's what you'll discover:

- The definition of a Test Chamber

- Various Test Chamber Designs

- Different Testing Methods for Test Chambers

- Categories of Test Chambers

- Industrial Applications of Test Chambers

- And many other valuable insights...

Chapter One – Understanding Test Chambers

A test chamber is a controlled environment specifically designed to evaluate the reliability, durability, and performance of various items including equipment, products, and materials. These chambers simulate real-world conditions that products might experience during actual use. Advanced test chambers can replicate extreme temperature fluctuations, varying humidity levels, and significant altitude changes.

Beyond environmental factors, test chambers can also assess product durability by applying physical stresses like inertia, vibrations, and impacts that may cause potential damage.

The burst test shown above measures the maximum pressure this cardboard sample can withstand before failure. This is one of many endurance tests conducted in test chambers.

Test chambers serve multiple purposes, such as:

- Preparing products for subsequent testing phases

- Independent testing of various material combinations

- Performing stress screening to identify potential defects during prototype development

Chapter Two – Exploring Test Chamber Designs

The design of test chambers primarily depends on the complexity and specific needs of the environmental tests they're built to perform. From basic temperature and humidity testing to sophisticated scenarios like altitude simulation, vibration analysis, and photostability testing, modern chambers have evolved to meet diverse industry requirements. They come in various sizes, suitable for different applications—from small benchtop chambers for testing electronics and material samples to large walk-in environmental rooms capable of accommodating vehicles, aerospace components, and industrial machinery.

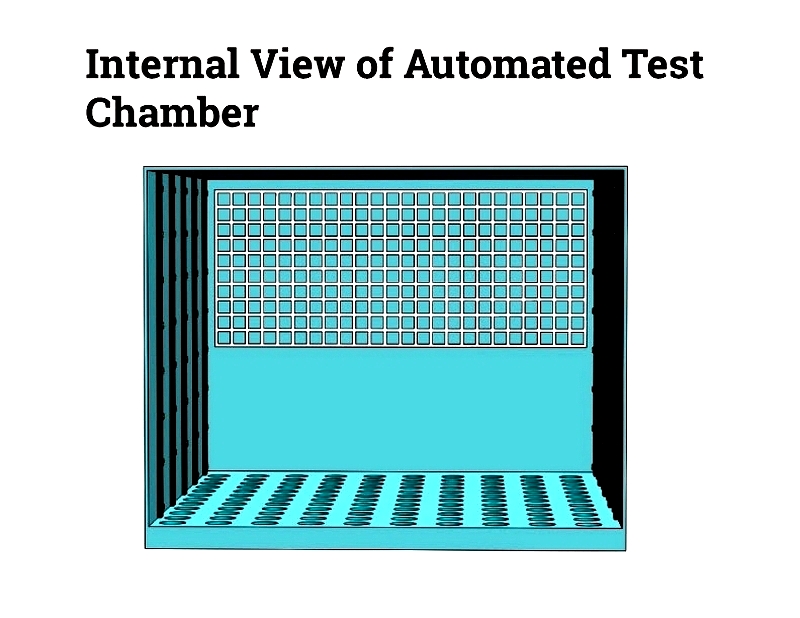

In addition to physical dimensions and environmental capabilities (such as temperature control, humidity regulation, thermal shock resistance, or dust testing), today's advanced chambers feature state-of-the-art control systems that offer real-time data, precise monitoring, and seamless adjustment of test conditions. This level of control is crucial for industries requiring rigorous product qualification testing. For extended stability assessments, steady-state test chambers (shown below) maintain exact parameters like temperature, humidity, and airflow for prolonged reliability testing and accelerated life evaluations.

Steady test chambers are specifically designed to maintain consistent, precise temperatures for aging tests, thermal cycling, and endurance evaluations. Features like airflow ducts, programmable logic controllers (PLCs), and sensor arrays ensure stable environments, while advanced data logging provides comprehensive reporting for regulatory compliance. These chambers are indispensable for electronics, automotive, and aerospace industries where meeting strict quality and product reliability standards is essential.

Key Design Considerations for Test Chambers:

Chamber Size

The size of a test chamber is determined by the type, dimensions, and intended use of the product being tested. Chamber capacities vary from compact one-cubic-foot units for testing integrated circuits or pharmaceutical packaging to custom-built enclosures exceeding 12,000 cubic feet for full-scale automotive, satellite, or aircraft testing. This versatility enables manufacturers to conduct various tests including accelerated weathering, salt spray, corrosion testing, and complete climatic simulations.

The images below show two different chambers: a compact ISO-compliant environmental chamber for testing industrial dryers, and a sophisticated walk-in chamber that replicates various temperature and humidity conditions. The walk-in chamber measures 8'x4'x4' and includes a wind-driven rain system capable of generating 160 mph (257 kph) winds. Such chambers are crucial for automotive component testing, aerospace validation, and military qualification where real-world conditions must be accurately simulated.

Chamber Controllers

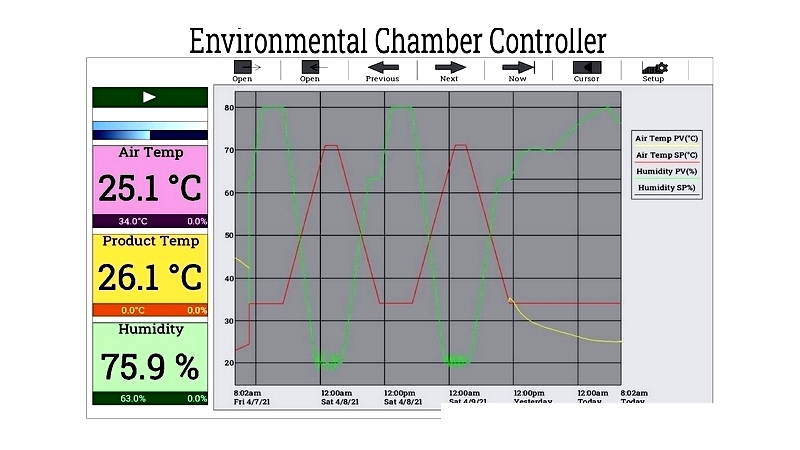

Modern test chamber controllers feature advanced microprocessor technology, intuitive touchscreens, and network connectivity for easy operation and data tracking. Engineers can monitor and control tests remotely via computers, tablets, or mobile devices. User-friendly interfaces display set points, real-time temperature and humidity readings, and graphical trends for multiple parameters. Unlike older systems that only provided post-test data, current controllers support instant alerts, customizable test profiles, automated data collection, and integration with laboratory information management systems (LIMS).

The controller display below shows digital and graphical tracking of air temperature, product temperature, and humidity—updated every second. These advancements ensure precise repeatability, compliance with international standards (like ASTM, MIL-STD, or IEC), and improved lab efficiency.

Chamber Automation

Automated test chamber systems enable laboratories to conduct complex, multi-variable tests involving thermal cycles, humidity changes, and pressure variations without manual intervention. Automated features include sequence programming for ramping (controlled parameter changes), soaking (maintaining target conditions), jumping (rapid transitions), and scheduled start/stop operations. These systems rigorously evaluate product endurance, lifecycle performance, and durability under accelerated aging or stress conditions. Robust PLC systems ensure accurate control and repeatability, making them ideal for high-throughput testing in R&D labs and manufacturing quality assurance.

Photostability Testing

Photostability testing chambers are specialized units that evaluate how products respond to light exposure, including sunlight simulation, UV radiation, and artificial lighting. This testing is vital for assessing photodegradation, color fading, and chemical breakdown in materials, pharmaceuticals, coatings, plastics, and inks. Results determine a product's light resistance, colorfastness, and compliance with international standards.

For pharmaceuticals and active ingredients (APIs), photostability chambers conduct forced degradation studies under controlled lighting and temperature to establish drug stability and shelf life. Since 1990, ICH Guideline Q1B photostability testing has been mandatory for pharmaceutical development, ensuring drugs remain stable during manufacturing, storage, and distribution.

The ICH outlines strict criteria in its Q1B guideline, specifying two light sources—Option 1 (fluorescent and UV lamps) and Option 2 (xenon or metal halide lamps)—to verify pharmaceutical product stability under simulated lighting conditions.

The image below shows a photostability test on spherical sensors, simulating UVA and visible light (VIS) conditions to analyze potential light-induced effects. These chambers also help researchers evaluate optical sensors, plastics, and coatings for color stability and performance.