Introduction

This article provides an in-depth exploration of various types of mills.

It covers detailed information on topics including:

- Principles of Mills

- Categories of Mills

- Types of Mills

- Applications and Benefits of Mills

- And More...

Chapter 1: What are the key principles of mills?

This section explores how mills operate and examines their typical components.

What is a Mill?

A mill is a machine designed to break solid materials into smaller pieces through cutting, grinding, or crushing. The milling process applies force to materials to reduce their size, enhancing ingredient effectiveness and final product quality. Milling falls into two main categories: dry milling, which relies on particle collisions, and wet milling, where materials are mixed in a slurry.

Mills come in various forms, each designed for specific materials. Early versions were hand-operated or powered by animals, wind, or water. Modern mills use electricity, offering greater power and reduced labor costs.

Milling involves applying mechanical force to break materials' internal bonds, converting solids into smaller particles or grains. It also includes sizing, separating, or classifying materials like mineral ores. For example, grinding rocks produces uniform particles for construction or separates rock from soil for land reclamation.

Milling also removes impurities or moisture from soil, creating dry fill for construction. The process serves several key engineering functions:

- Maximizing surface area before reaction or dissolution

- Achieving precise grain size

- Reducing pulp

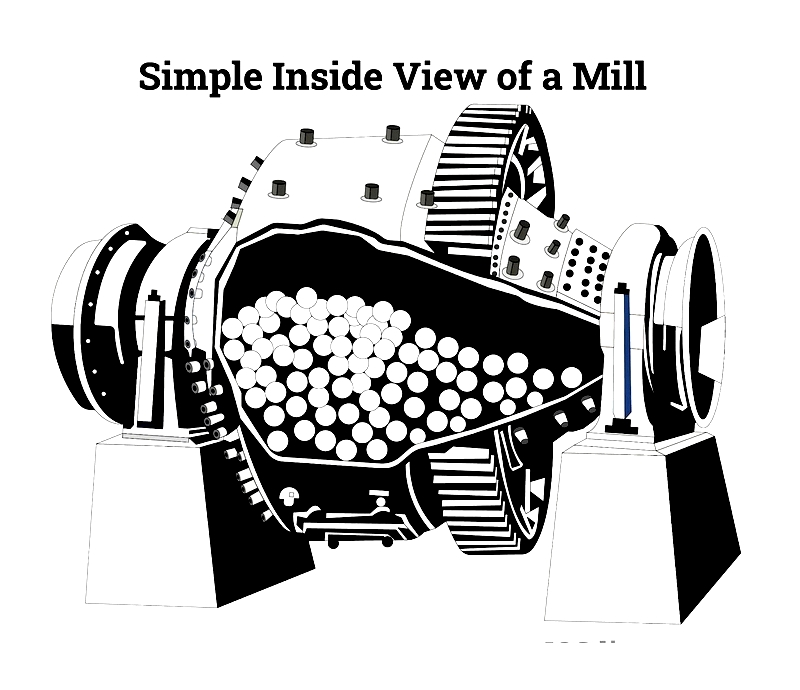

Chapter 2: What are the Main Components of an Industrial Mill?

Industrial mills are advanced mechanical systems for grinding and reducing material size across industries like mining, cement production, and chemical processing. These complex machines consist of critical parts working together for efficient performance. While designs vary—such as ball mills, rod mills, SAG mills, and autogenous mills—all share core components built for strength, durability, and safety. Understanding these components helps operators maintain and optimize milling equipment for maximum productivity.

Shell

The mill shell is the primary structural element, acting as both containment and support for internal components. Made from thick steel plates, it's welded into a cylindrical or conical shape to resist distortion and vibration. Shell diameter, length, and thickness are tailored to production capacity and material abrasiveness. Precision-drilled holes accommodate liners and bolting systems. Shell integrity is vital for reliability, especially in large-scale mining operations.

Flanges

Mill flanges are precision-engineered to match specific diameters and operational needs. They maintain strict tolerances to prevent leaks and wear. Regular inspections ensure balance and surface quality, preventing warping and premature failure for prolonged uptime.

Shell Liners

Shell liners protect the shell's interior from abrasive wear. Material and profile choices—like rubber for ball mills or high-manganese steel for SAG mills—affect efficiency and lifespan. Common liner types include:

- A C Lorain Shell Liners – Carbon steel liners with raised lifters for impact absorption.

- Wave Ball Mill Shell Liners – Integrated units creating wave-like motion for efficient grinding.

- Wedge Shell Mill Liners – Bolt-free liners for quick change-outs.

- Mill Spiral Shell Liners – Spiral-contoured liners for uniform grinding.

Heads

Mill heads are end caps made from cast or forged steel, sealing the shell. Designs include conical heads for better discharge and starfish designs for reinforced support. Trunnion bearings enable smooth rotation.

Pinion Shaft

The pinion shaft transfers power from the drive system to the mill's ring gear. High-performance bearings and proper lubrication ensure efficient operation.

Mill Drive

Mill drive systems vary by size and demand. Smaller mills use V-belt drives, while larger ones employ direct-drive systems for better efficiency.

Mill Feed Chutes

Feed chutes deliver materials consistently. Types include:

- Spout Feeder – For coarse or abrasive materials.

- Scoop Feeder – Handles fine particles and grinding media.

- Drum Feeder – For single-pass grinding.

- Combination Feeder – Versatile for complex setups.

Discharge Unit

The discharge system determines particle size and consistency. Common types are:

- Overflow Discharge Mill – For fine particles.

- Peripheral Discharge Mill – For coarse grinding.

- Diaphragm Discharge Mill – Separates media from product.

Industrial Mill Grinding Media

Grinding media reduce materials to fine particles, crucial for industries like mining and ceramics. Selection impacts performance and efficiency.

metallic Grinding Media

Made from steel or chrome steel, these media come as balls, rods, or cylinders. They suit high-impact grinding in ball and rod mills.

Non-metallic Grinding Media

Designed to minimize contamination, these include alumina oxide and zirconium oxide. They're ideal for pharmaceuticals and ceramics.

Consulting manufacturers helps select the best media for each application.