Introduction

This guide provides comprehensive information about nylon brushes.

You'll explore various topics including:

- What defines a nylon brush?

- The manufacturing process of nylon brushes

- Different types of nylon filaments

- Varieties of nylon brushes

- And additional valuable information

Chapter 1: What is a Nylon Brush?

A nylon brush features filaments made from nylon polymer, a material prized for its exceptional toughness, durability, flexibility, and elasticity. These widely used bristles provide superior abrasion resistance, making them the most popular choice in brush manufacturing. The remarkable resilience of nylon-bristled brushes stems from their ability to endure high temperatures (up to 350°F) and resist various chemicals.

The term "nylon" describes a family of synthetic polymers known as polyamide nylons. Since DuPont's development in 1938, nylon has become a versatile synthetic material with countless applications.

Chapter 2: How Nylon Brushes are Made

Nylon brushes serve as essential tools across numerous industries, from manufacturing and automotive detailing to cleaning, surface finishing, and personal grooming. Typically consisting of durable nylon filaments and sturdy handles, these brushes undergo meticulous manufacturing processes tailored to specific cleaning, polishing, deburring, or scrubbing applications. Variations arise from handle types, filament shaping, and selection of filament grades and abrasives—all influencing performance and longevity.

High-quality nylon brush production involves advanced manufacturing techniques, custom engineering, and precision assembly, each designed for specific demanding environments. While general-purpose brushes feature bristles attached to handles, industrial-grade brushes employ specialized methods to withstand extreme abrasion, chemicals, or high-speed rotation. This variety enables applications in cleaning, deburring, finishing, powder coating, electronics, conveyor cleaning, and more.

Filament Selection and Types

Selecting appropriate nylon filaments represents the most crucial step in brush design, determining durability and application suitability. Common types include nylon 6, 66, 610, 612, 11, and 12, each offering unique flexibility, wear resistance, and water absorption characteristics. Engineers often choose abrasive nylon filaments infused with silicon carbide, aluminum oxide, or aluminum silicate for effective deburring, surface finishing, or aggressive cleaning.

Industry applications dictate whether abrasive or non-abrasive bristles are preferable. Abrasive filaments excel at rust removal, while softer bristles suit gentle dusting or cosmetic uses. Filament diameter, length, stiffness, and chemical compatibility are critical considerations for food processing, pharmaceuticals, electronics, or facility maintenance applications.

Handle Materials and Configurations

Handle selection impacts ergonomics, functionality, strength, and resistance to chemicals or heat. Specialized brushes may feature metal handles for power tool attachment, while others offer ergonomic wood or plastic designs for handheld use. Industrial handles often utilize corrosion-resistant materials like stainless steel for harsh environments, making these brushes indispensable across janitorial, automotive, and surface preparation applications.

Brush Manufacturing Techniques

Manufacturing methods vary based on brush size, bristle density, handle material, and attachment technique. Reliable filament attachment proves crucial, especially for high-torque applications where bristle retention affects performance and safety. Common construction methods include twist-in wire, staple set, and strip brush assembly, each suited to specific applications from automotive manufacturing to delicate laboratory work.

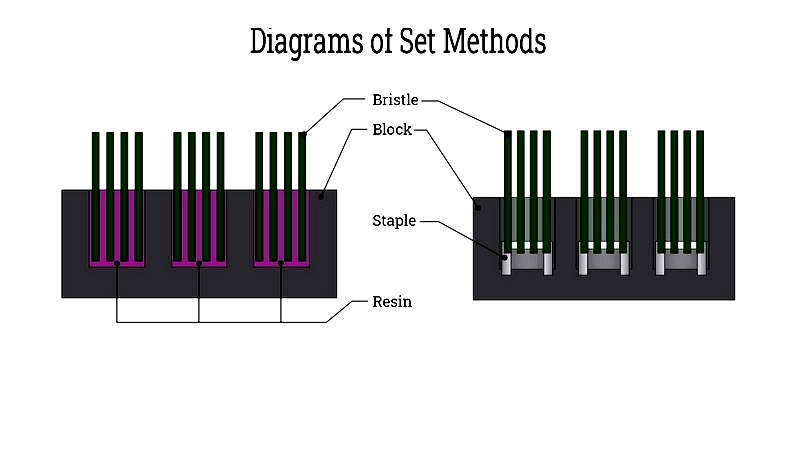

Staple Set Method

Staple set brushes involve drilling holes in wood or plastic blocks for uniform bristle distribution. Filaments are inserted and anchored via U-shaped staples, resin embedding, or bar anchors, ensuring stability during strenuous use. Hole diameters typically range from 0.078 to 0.437 inches, with straight or staggered patterns affecting cleaning efficiency.

U-Shaped Staple Method

This technique loops filaments into U-configurations secured by metal staples penetrating deep into the handle, preventing filament loss during aggressive cleaning.

Bar Anchor Method

A flat metal bar reinforces pre-drilled holes, pinning filaments securely for industrial applications requiring enhanced durability.

Epoxy or Resin Set

For contamination-sensitive environments like food processing, advanced adhesives embed bristles without metal components, sometimes combined with staples for added strength.

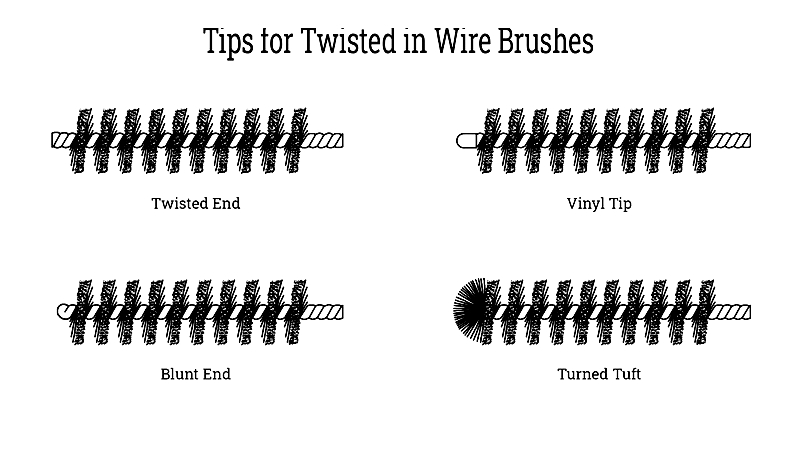

Twist-In Wire Brushes

Manufactured by twisting filaments between wire strands, these brushes withstand rotary action, making them ideal for tube, cylinder, or hard-to-reach area cleaning. Automotive mechanics, maintenance crews, and industrial cleaners commonly use these versatile tools.

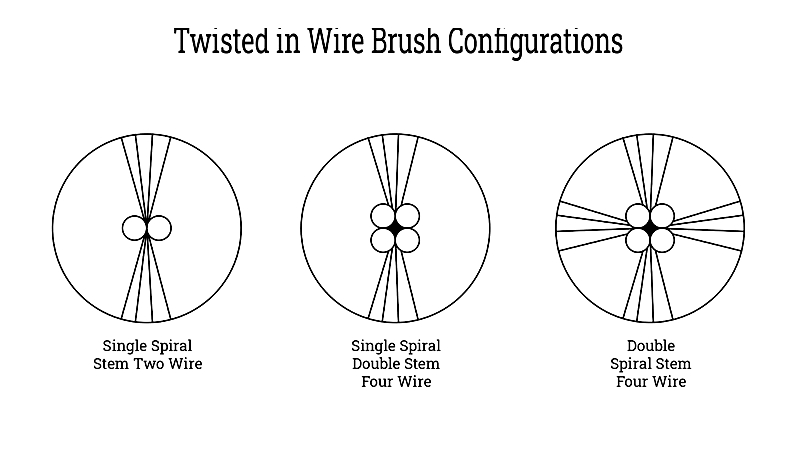

Single Spiral and Stem Two Wire Brush

Featuring bristles held between two twisted wires, this compact design suits small tube and valve cleaning.

Single Spiral Double Stem Four Wire Brush

Four-wire spirals increase filament density for enhanced cleaning power in automotive and aerospace maintenance.

Double Spiral and Stem Four Wire Brush

Perpendicular filament layers maximize surface coverage for large-scale industrial cleaning applications.

Twist-in wire brush handles range from molded plastic to wooden grips, while some omit handles entirely for direct power tool attachment in industrial cleaning operations.

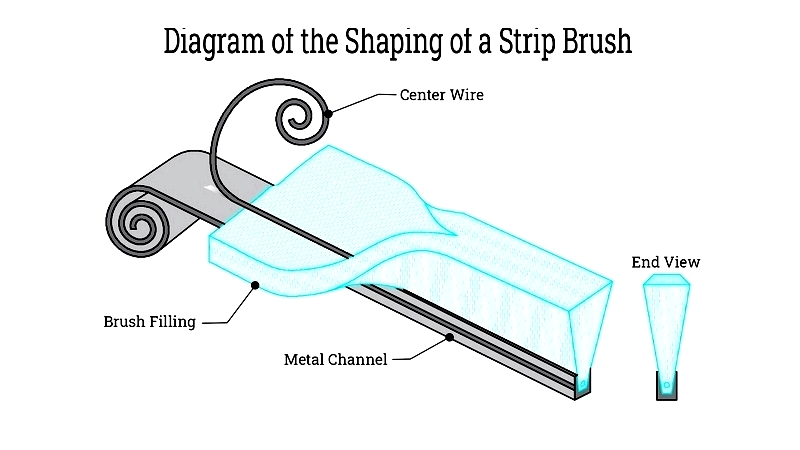

Strip Brushes

Constructed by compressing filaments over metal strips with central wires, these continuous brushes excel in conveyor cleaning, weatherstripping, and static control applications within material handling and packaging industries.

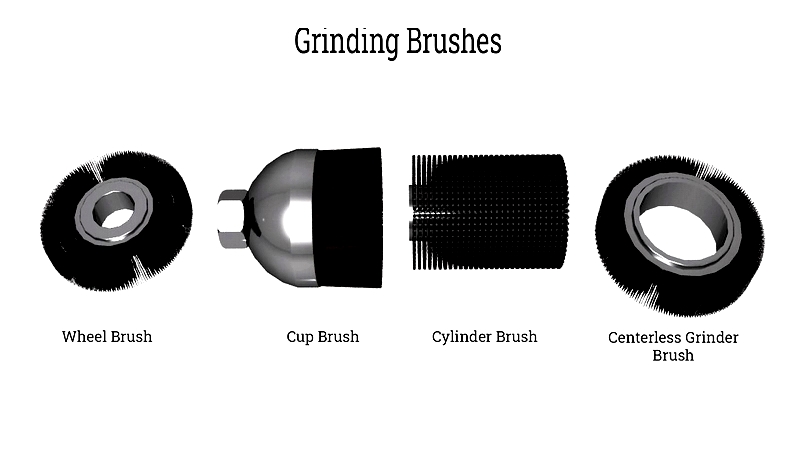

No Handle: Direct-Mount and Power Tool Brushes

Specialized brushes designed for direct equipment attachment include cylindrical, cup, wheel, and floor scrubbing configurations. These tools serve heavy-duty cleaning, rust removal, static elimination, and precision finishing tasks across industrial and commercial settings.

Choosing the Right Nylon Brush for Your Application

Key selection factors include filament material, grit size, brush shape, mounting style, and chemical compatibility. Abrasive nylon brushes suit demanding industrial tasks, while softer bristles work best for delicate cleaning. Consulting manufacturers ensures optimal brush design for specific cleaning efficiency, surface quality, and operational safety requirements across commercial cleaning, food processing, laboratory, and automotive applications.