Introduction

This article provides in-depth industry insights about plastic containers. Continue reading to explore:

- What are Plastic Containers?

- Overview of Plastics

- Advantages of Plastic Containers

- Types of Plastic Containers

- And much more…

Chapter 1: Understanding Plastic Containers

Plastic containers are storage units made from various polymers derived from crude oil or natural gas. These polymers are produced through complex chemical processes that convert petroleum into thermoplastics. The materials are specially engineered to be molded into durable, long-lasting transport and storage containers. Since their introduction during the industrial revolution, plastic containers have become essential for industrial and logistics applications.

Production methods vary depending on specifications. Smaller containers are typically made through injection molding, while larger uniform containers use rotational molding. These advanced techniques enable the creation of diverse plastic products, from drink bottles to large shipping containers.

The history of plastics dates back to the 1840s when German scientist Eduard Simon discovered polystyrene. This breakthrough was followed by celluloid development, marking the start of polymerization. Initially used for bottles, plastic containers expanded rapidly in the 1930s with cellulose acetate. Later, materials like LDPE and PVC emerged, revolutionizing mass production.

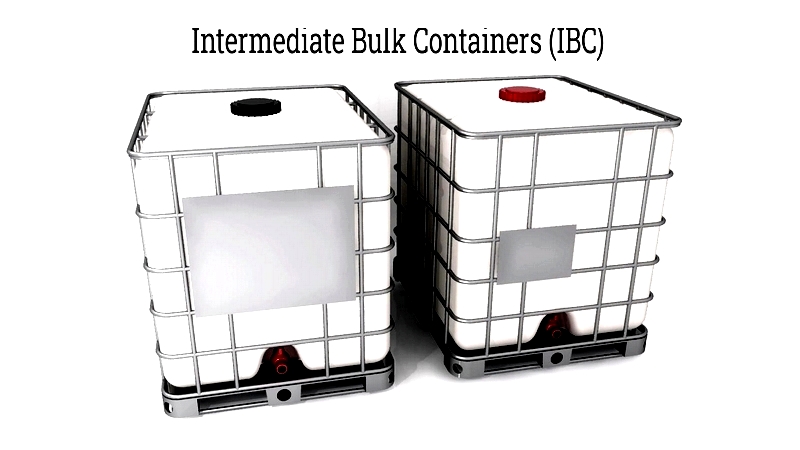

Today, plastic containers come in numerous styles and sizes. Advances in production have led to large-volume containers, transparent clamshell packs, and impact-resistant cases. In 2018, the global plastic container market was valued at $86 billion, with projected 4% annual growth through 2025. Key industries relying on plastic containers include food and beverage, pharmaceuticals, cosmetics, household products, and industrial lubricants.

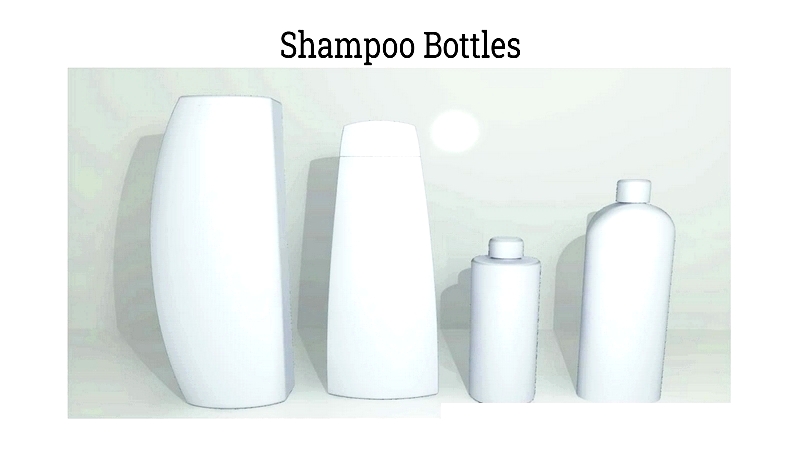

The most common material for plastic containers is PET, used for water and juice bottles. HDPE is another popular choice, often used for shampoo, cleaner, and detergent packaging.

Chapter 2: Overview of Plastics

Plastics are synthetic materials primarily made from petroleum-based compounds. Common building blocks include ethylene, propylene, styrene, and acetylene. These monomers undergo polymerization to form polymer chains, the foundation of plastic production. This process enables the creation of materials with diverse properties, making plastics essential for packaging, automotive, medical, construction, and electronics industries.

Manufacturing involves polymerizing monomers to create chains. Additives like plasticizers and stabilizers are blended to enhance properties such as strength, flexibility, and UV resistance. Plastics are then molded into final products through techniques like injection molding and extrusion.

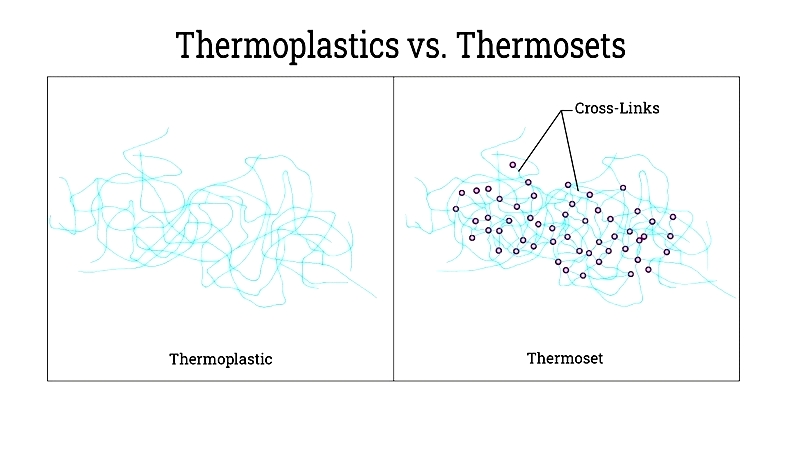

Plastics are categorized into two main types: thermoplastics and thermosets, which determine their processing and application characteristics.

Thermoplastic Polymers

Thermoplastics can be reshaped through heating and cooling cycles without chemical change. They soften when heated and harden when cooled, making them suitable for injection molding and extrusion. Common types include PE, PP, PVC, and PS, used in packaging, pipes, and automotive parts.

Thermosetting Polymers

Thermosets form permanent crosslinks during curing, becoming rigid and heat-resistant. Unlike thermoplastics, they cannot be reshaped after curing. Examples include epoxy and phenolic resins, used in composites, circuit boards, and structural components.

Choosing the Right Plastic Material: Selecting between thermoplastics and thermosets depends on mechanical requirements, environmental conditions, lifespan, and cost. Engineers often consult technical data and suppliers to choose optimal materials for specific applications.

For material sourcing, working with reputable suppliers ensures access to quality polymers and technical support. Many companies offer custom compounding and compliance documentation to meet industry standards.