Introduction

This article provides an in-depth exploration of pneumatic cylinders.

Continue reading to discover key topics including:

- What pneumatic cylinders are

- Pneumatic cylinder components

- Different types of pneumatic cylinders

- Mounting methods for pneumatic cylinders

- ISO standards for pneumatic cylinders

- Additional important information

Chapter 1: Understanding Pneumatic Cylinders

Pneumatic cylinders are mechanical devices that generate force using compressed air. These systems typically include a piston, piston rod, and cylindrical housing. As air enters one end of the cylinder, internal pressure increases, causing the piston to move in a specific direction. The piston rod then transfers this motion to the object requiring movement.

Compressed air serves as the working fluid in pneumatic cylinders, making them ideal for applications requiring clean operation. Any potential leaks won't contaminate the surrounding environment. Additionally, these cylinders operate quietly and don't require large storage tanks for their working medium.

Pneumatic cylinders play a vital role in industrial processes by providing force and motion for operations like clamping, ejecting, blocking, and lifting. In manufacturing environments, they're commonly used for repetitive tasks such as transferring items between machines. They're also effective for controlling valve operations in piping systems.

Chapter 2: Pneumatic Cylinder Components

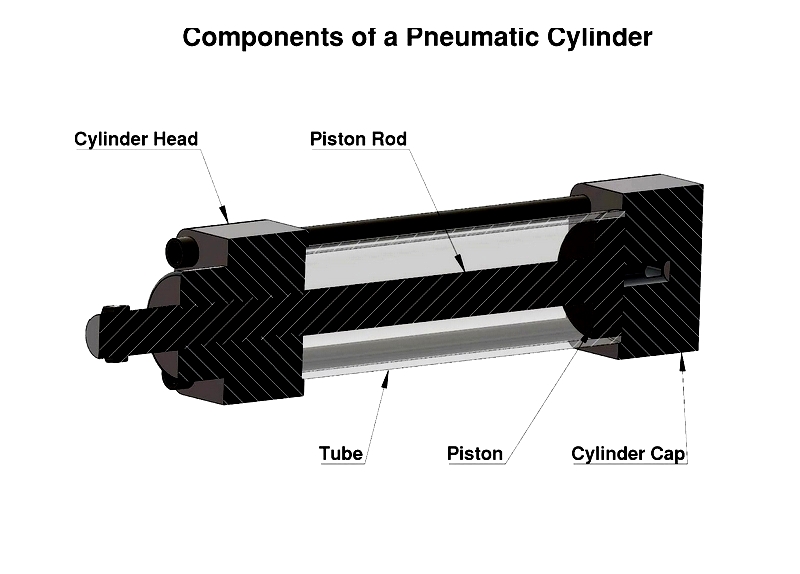

Pneumatic cylinders, sometimes called air cylinders or actuators, are crucial elements in industrial automation. They transform compressed air energy into linear motion and mechanical force, powering machinery across various applications from manufacturing to robotics. Knowing the key components helps users select, maintain, and optimize these devices for peak performance.

- Cylinder Bore: The main body serves as the pressure vessel, housing all internal components. Precision-machined for airtightness, it features two end caps: the front-end (cylinder head) and rear-end (cylinder cap). Air ports in the caps allow compressed air entry, while seals prevent leakage. Typically made from aluminum or stainless steel, these tubes withstand industrial conditions.

- Piston: This internal disc divides the cylinder into two chambers. Compressed air pressure moves the piston along the bore, extending the rod in a power stroke. The return mechanism varies by cylinder type, with single-acting models using springs and double-acting models using air pressure. Force output depends on air pressure multiplied by piston area.

- Piston Rod: This precisely machined component transfers piston force to external loads. Its stroke length determines motion range, while surface treatments like chrome plating enhance durability.

- Piston Cushioning: This feature reduces piston speed at stroke ends, minimizing shock and noise while enabling higher cycle speeds.

- Piston Seals: These create airtight barriers - static seals between piston and rod, while piston seals separate the chambers.

- Guide Rings: Made from materials like PTFE, these wear bands prevent metal contact between piston and bore, reducing friction.

- Sensors: Integrated position detectors enable precise control through magnetic reed switches or Hall-effect sensors.

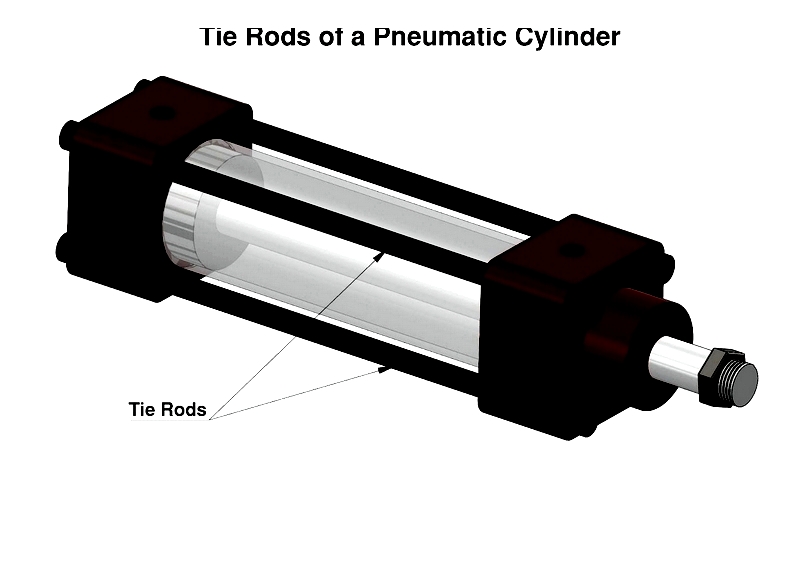

- Tie Rods: These threaded steel rods secure end caps to the bore, maintaining structural integrity under pressure. Common in ISO/NFPA standard cylinders, they offer easy maintenance and impact protection.

When selecting pneumatic cylinders, consider factors like cylinder type, bore size, stroke length, mounting style, and operating pressure. Special features like adjustable cushioning or sensors may enhance performance. Reputable manufacturers provide details on materials, maintenance, and compatibility to optimize system uptime.

For expert guidance on cylinder selection and integration, consult leading industry suppliers. Understanding these components helps users make informed decisions throughout the product lifecycle.