Introduction

This article provides an in-depth exploration of metal fabrication.

After reading, you'll gain knowledge about:

- The definition of metal Fabrication and its key steps

- Various metal Fabrication Processes

- Technologies, materials, and considerations in metal Fabrication

- Benefits, limitations, and applications of metal Fabrication

- And much more...

Chapter 1: Understanding metal Fabrication and Its Comprehensive Process

metal fabrication involves shaping flat metals and sheet metals into specific forms. The process begins with metal sheets typically under a quarter-inch thick, allowing flexibility for various shaping techniques. Fabricators transform these sheets through methods like cutting, stamping, folding, and welding. Custom fabrication combines these processes to create specialized components.

Stages in metal Fabrication

Design Phase

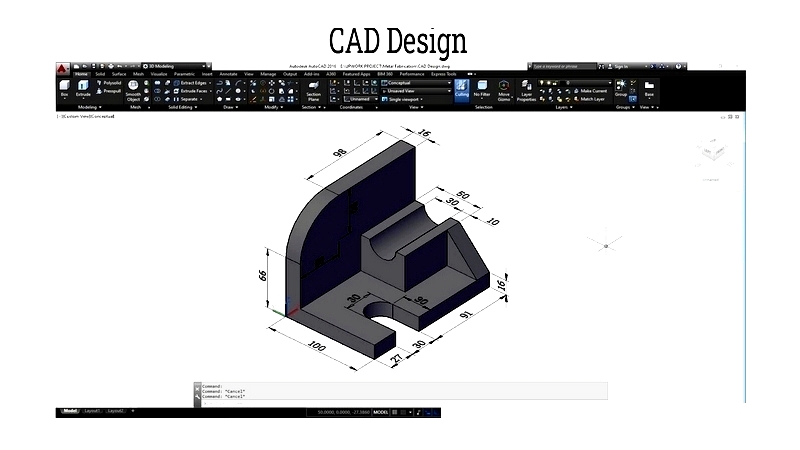

The design phase involves optimizing component designs for production. This stage includes standard designs or custom creations, often requiring client collaboration for unique specifications. Designers use CAD software to develop plans, working with customers to establish project goals and production methods. This collaboration ensures designs align with manufacturing techniques, known as steel detailing.

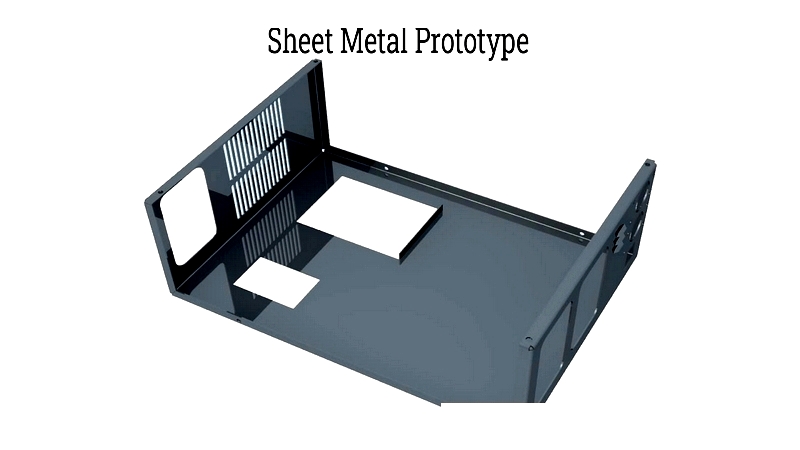

Prototyping Phase

Prototyping follows design and is crucial for custom projects, allowing clients to preview final products. Techniques like rapid sheet metal prototyping or 3D printing create physical samples for evaluation, ensuring design compatibility before full production.

importance of Sheet metal Prototyping

Prototyping is essential for successful metal product development. Skipping this step in large-scale production can lead to costly modifications, material waste, and delays. Proper fabrication requires thorough testing from design to manufacturing to avoid future expenses. Prototyping also helps visualize final products more effectively.

Rapid Prototyping Techniques

Using 3D CAD technology, rapid prototyping quickly produces physical models. Additive manufacturing (3D printing) accelerates development by validating product fit and function early, ensuring final products meet technical and business requirements.

Programming Stage

After finalizing CAD designs, they're converted into programming codes for computer-controlled equipment. This step is vital for automated machinery like cutting and punching machines.

Fabrication Process

Fabrication begins after programming. Production time depends on component complexity, methods used, and shop workload. Processes include cutting, punching, folding, machining, and welding.

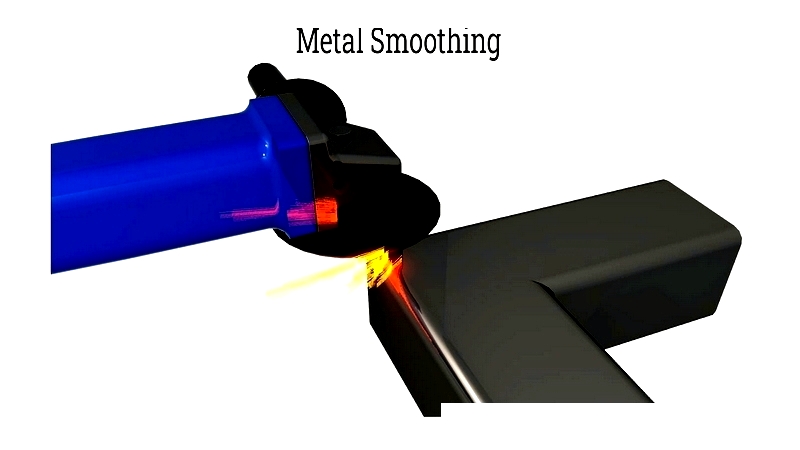

Final Finishing

Post-production finishing may involve surface smoothing and protective coatings like powder coating to meet quality standards.

Assembly Services

Some fabricators offer assembly services, including electrical hookups and welding to complete products.

Chapter 2: metal Fabrication Processes

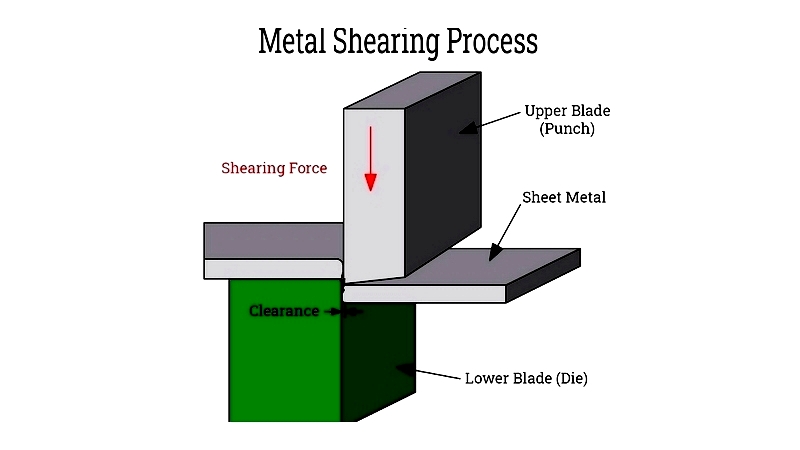

Shearing

Shearing efficiently creates precise, straight-line cuts in sheet metal using opposing tools. The upper blade initiates a fracture while the lower tool supports the material. This process is common in automotive and aerospace industries for dimensional accuracy. Additional finishing may refine cut edges.

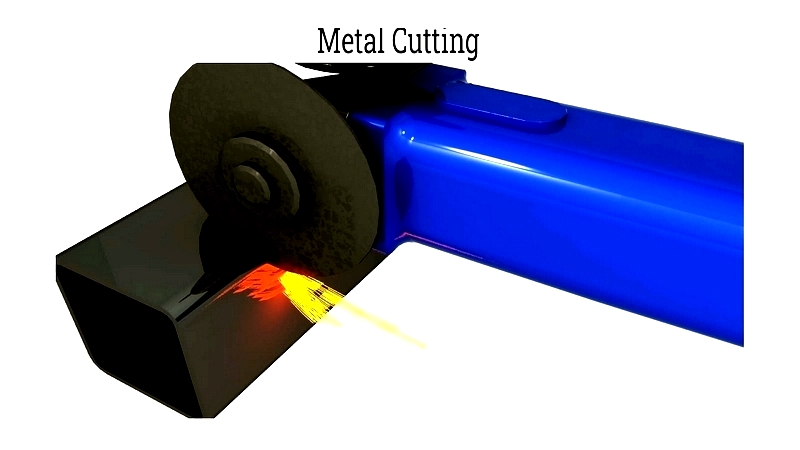

Cutting

Cutting separates metal into manageable sections. Traditional sawing remains popular, while laser, waterjet, and plasma cutting offer advanced precision. Die cutting produces consistent shapes for high-volume components like gaskets and washers.

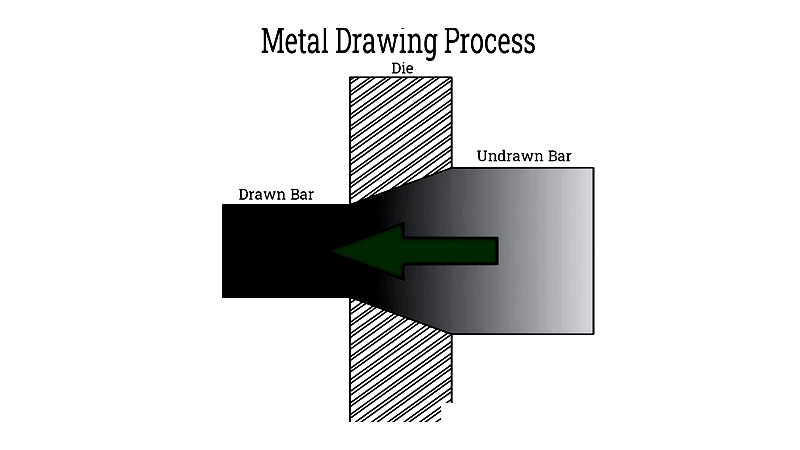

Drawing

Drawing elongates metal by pulling it through a die, creating wires, tubes, and rods. Cold drawing achieves tight tolerances, while hot drawing reduces force for larger sections. Deep drawing forms hollow shapes like cans and fuel tanks.

Welding

Welding joins metals using heat and pressure. Common methods include FCAW, MIG/GMAW, SMAW, and TIG welding. Each suits different materials and applications, from automotive chassis to precision components.

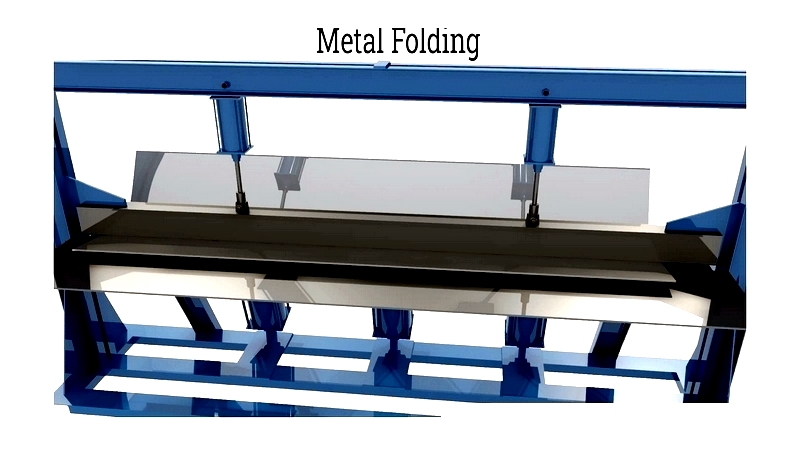

Folding

Folding creates complex bends in sheet metal using brake presses or manual folders. CAD/CAM integration ensures accuracy in intricate patterns, benefiting electrical enclosures and brackets.

Forging

Forging shapes metal using compressive force, enhancing strength. Methods include cold forging for fasteners, warm forging for intricate parts, and hot forging for large components like gears.

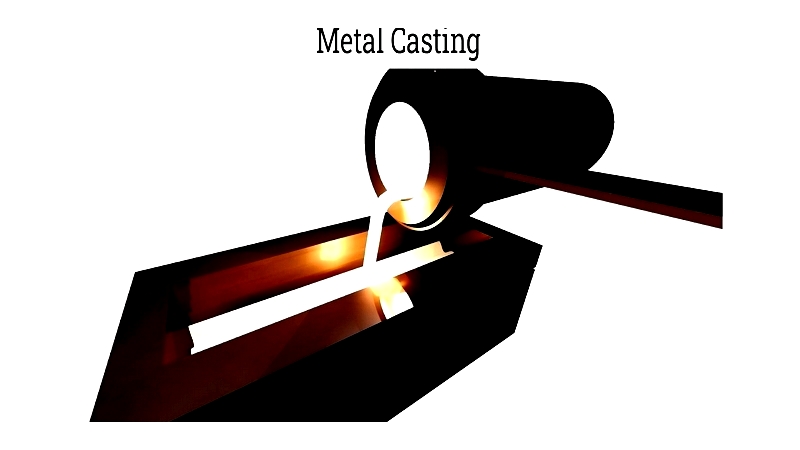

Casting

Casting pours molten metal into molds for complex parts. Techniques like die casting, permanent mold casting, and sand casting suit different production needs, from automotive to industrial applications.

Extrusion

Extrusion forces metal through dies to create uniform profiles. Hot extrusion works for larger shapes, while cold extrusion produces stronger products with tighter tolerances.

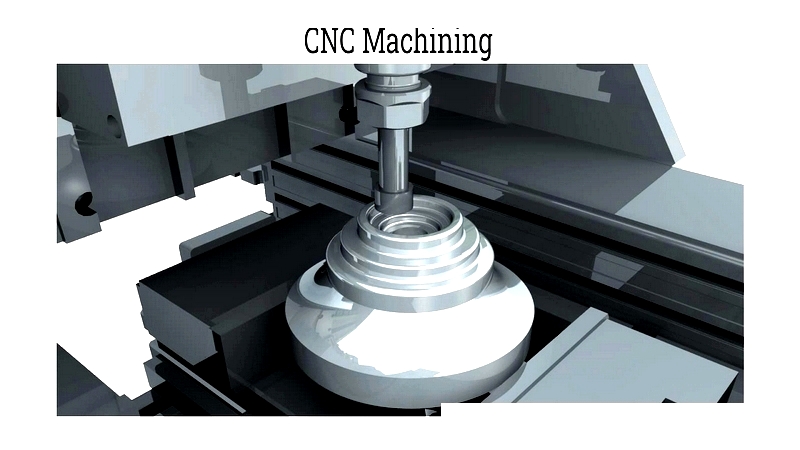

Machining

Machining removes material to create precise parts. CNC technology improves accuracy in milling, turning, and drilling operations for various industries.

Stamping

Stamping uses dies to create features on sheet metal. Mechanical and hydraulic presses enable mass production of components like automotive panels and electronic parts.