Introduction

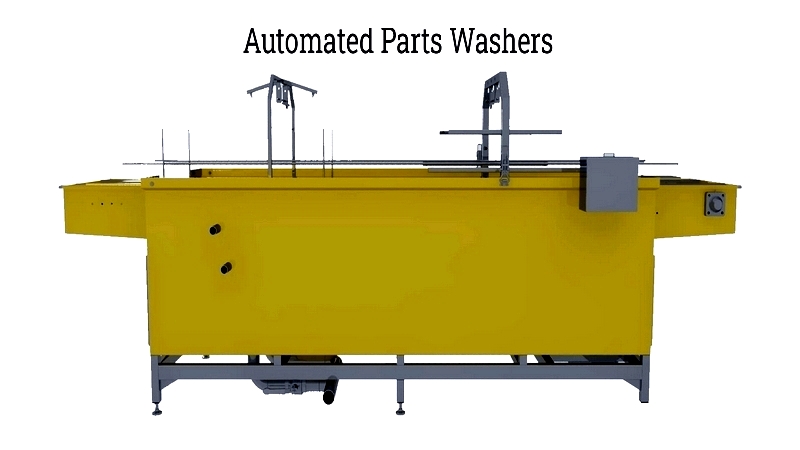

This article provides an in-depth exploration of automated parts washers.

Key topics covered include:

- Working Principles of Automated Parts Washers

- Design and Functionality of Automated Parts Washers

- Different Types of Automated Parts Washers

- Applications and Advantages of Automated Parts Washers

- And more...

Chapter 1: Fundamentals of Automated Parts Washers

This chapter offers a thorough introduction to automated parts washers and their operational principles.

What Are Automated Parts Washers?

Automated parts washers are advanced cleaning systems designed to efficiently remove contaminants like grease, oil, dirt, and paint with minimal human intervention. During manufacturing, lubricants and chemicals are essential for smooth operations but must be thoroughly cleaned before assembly, packaging, or coating processes.

These systems have evolved significantly, now operating autonomously with sophisticated software that manages loading, washing, rinsing, and drying processes. Automation reduces labor costs, increases productivity, improves cleaning quality, and handles large part volumes efficiently.

Available in various configurations including high-pressure washers, cabinet washers, and rotary basket washers, these systems can clean parts of any size or complexity. This ensures manufacturers achieve superior cleaning results and enhanced product quality.

Using water-based solvents and chemicals, automated washers effectively remove production residues. This cleaning stage prepares parts for subsequent processes like coating, which require pristine surfaces for optimal adhesion.

Manufactured parts often contain burrs, dust, or paint residues. Their complex geometries with grooves, holes, and tight spaces present cleaning challenges that automated washers are specifically designed to address.

Chapter 2: Design and Functionality of Automated Parts Washers

Designing automated parts washers requires careful consideration of multiple engineering factors to ensure optimal cleaning performance. Key aspects include part size, geometry, and configuration, as well as weight and features like blind holes, tight angles, and complex surfaces. Engineers must also consider throughput, automation compatibility, energy efficiency, and industry-specific cleanliness standards for sectors like automotive, aerospace, and medical device manufacturing.

Effective parts washer development incorporates various automation solutions such as CNC controls, loading systems, rotary tables, and conveyor belts. Most modern systems use aqueous cleaning methods with water-based solvents for safe, efficient degreasing. Each washer is custom-designed to meet specific processing needs while complying with industry standards like ISO 16232.

Typical components include filtration systems, variable-speed pumps, high-pressure scrubbers, water heaters, and durable cabinets. These elements work together to deliver consistent, reliable cleaning for industrial and precision parts.

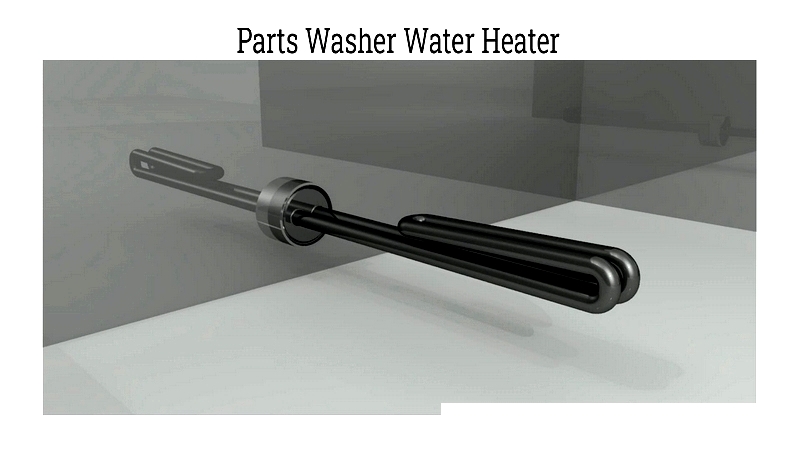

Water Heater Systems

The water heater is a vital component that rapidly heats cleaning solutions for more effective cleaning. Available in gas, electric, or steam models, it enhances detergent activation for better removal of oils and greases. Temperature control is particularly important for stringent cleanliness requirements.

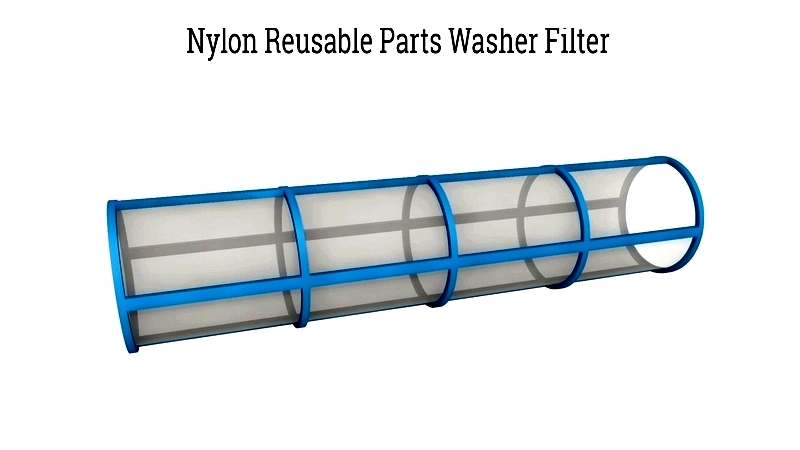

Filtration Systems

High-performance filtration maintains cleaning solution longevity and prevents debris buildup. Systems typically include coarse filters for heavy soils and fine filters for smaller particles. Effective filtration improves cleaning results while reducing maintenance and water usage.

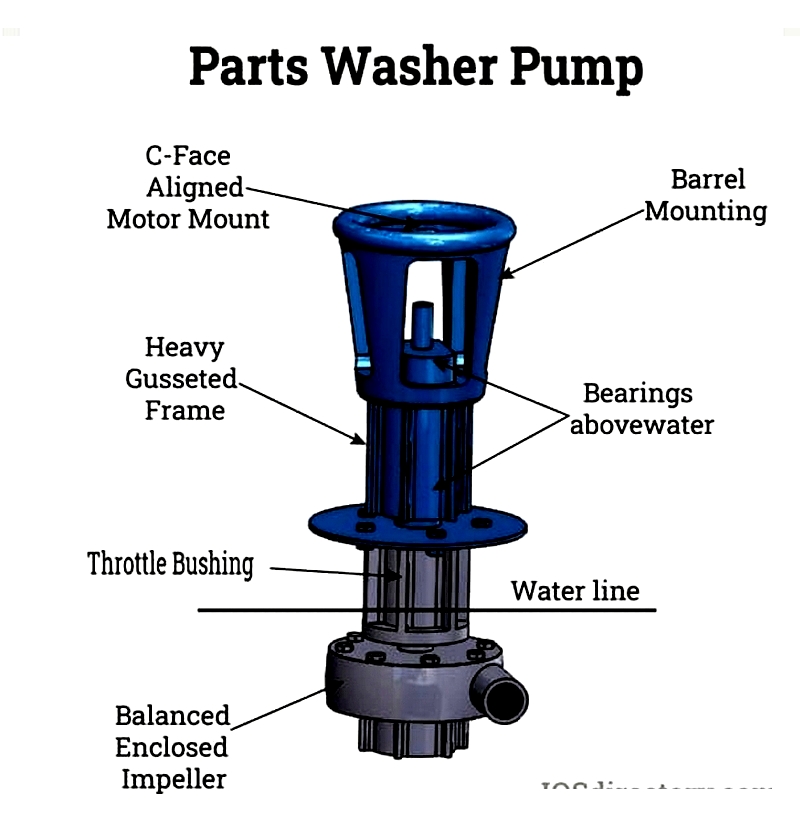

Pump Systems

Industrial pumps circulate cleaning fluids through the system, operating at temperatures up to 185°F (85°C) with flow rates of 115 GPM and pressures of 65 psi. Proper pump performance is crucial for removing microscopic contaminants in precision applications.

Regular maintenance ensures consistent performance and prevents incomplete cleaning that could compromise part quality.

Scrubbing Technology

Scrubbers use high-pressure sprays or rotating brushes to remove stubborn contaminants. Customizable settings allow adaptation to different materials and cleaning requirements.

Cabinet Design

Cabinets come in various sizes with features like adjustable racks and drainage systems. Constructed from corrosion-resistant materials, they withstand chemical exposure and high-pressure cleaning.

Safety Features

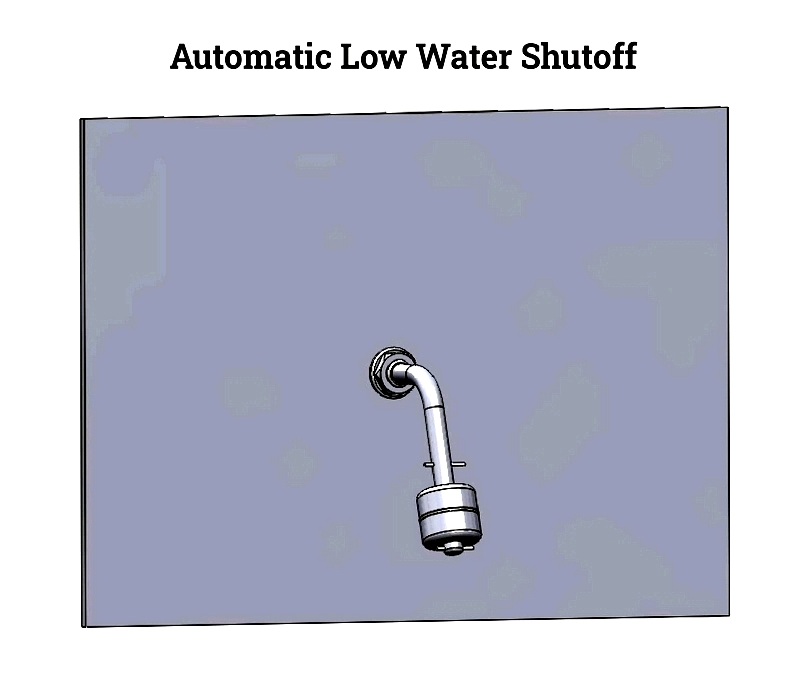

Low-water shutoff systems automatically stop operation when fluid levels drop, protecting equipment and ensuring safety. Systems resume only when proper levels are restored.

Cleaning Solutions

The choice between aqueous and solvent-based cleaners depends on contaminant type, substrate material, and regulatory requirements. Many facilities now prefer aqueous solutions for environmental compliance.

Solvent-based Cleaners

Solvent cleaners effectively dissolve tough oils and greases. Modern formulations focus on low VOC content and environmental safety, often incorporating recycling capabilities.

Aqueous-based Cleaners

Aqueous solutions combine water with detergents and additives, using mechanical action and heat for cleaning. They support environmental goals and reduce operating costs.

When selecting a system, consider cycle times, automation features, maintenance needs, and manufacturer support. Consulting with experts helps identify the optimal solution for your specific requirements.