Introduction

This article provides an in-depth exploration of paint spray booths.

Key topics covered include:

- What is a Spray Booth?

- Common Construction Principles of Spray Booths

- Types & Configurations of Spray Booths

- Applications and Benefits of Spray Booths

- And More...

Chapter 1: Understanding the Principle of Paint Spray Booths

This chapter explains the concept of spray booths, focusing on their standard structural design and operational mechanisms.

Defining a Spray Booth

A spray booth, often called a paint spray booth, is a specialized enclosure designed for spray painting projects. It effectively contains and removes overspray and vapors generated during the painting process.

Spray booths are commonly used to apply protective coatings to metal surfaces, preventing corrosion. These booths are engineered for safety, featuring fire and explosion-resistant properties. They are ideal when environmental conditions make outdoor or open indoor painting impractical. Factors like adverse weather, hazardous materials, worker safety concerns, temperature control, and vapor containment make spray booths the optimal choice.

For example, painting pipes in freezing temperatures may harm workers or affect coating properties, causing freezing, vaporization, or liquefaction. In such cases, a temperature-controlled spray booth provides an effective solution.

Building a Spray Booth

A spray booth typically consists of several key components, including:

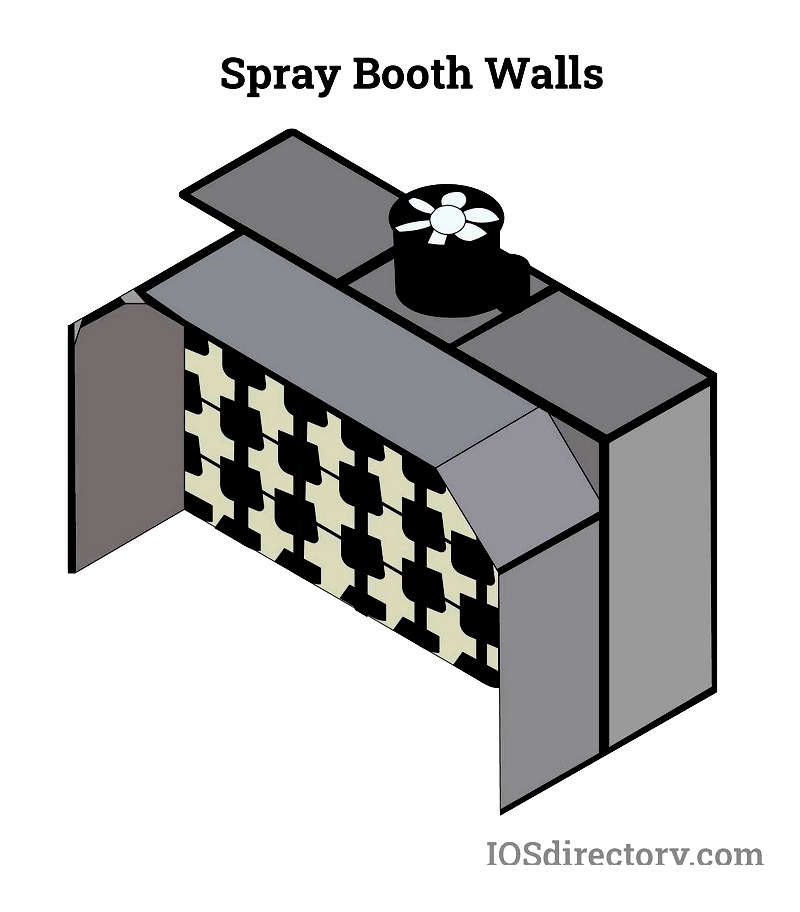

Walls of the Spray Booth

Paint booths feature single-skin or dual-skin walls, each offering distinct cost and quality advantages.

Single-skin panels are durable and cost-effective, providing quality without compromise. Their external flanges create a smooth interior for easy cleaning.

Dual-skin panels enhance durability and longevity. These panels offer a polished appearance and insulation, maintaining warmth while reducing noise and heat transfer.

White pre-coated walls, common in dual-skin setups, improve visibility by reflecting light, making painted surfaces easier to inspect.

Doors in Spray Booths

Doors allow entry for vehicles, parts, and items to be painted. The door type depends on whether the booth is pressurized. Maintaining positive or negative pressure relative to the environment is crucial. Positive pressure prevents debris entry, while negative pressure contains emissions and VOCs.

Non-pressurized booths use filtered doors to block contaminants, while pressurized booths require solid doors with filtered intake plenums.

Roll-up doors, made of galvanized steel, aluminum, or cloth, are ideal for pressurized booths with space constraints. They feature triple-layered cloth and airtight seals to prevent overspray escape and maintain curing temperatures. Personnel doors with optional observation windows provide quick access.

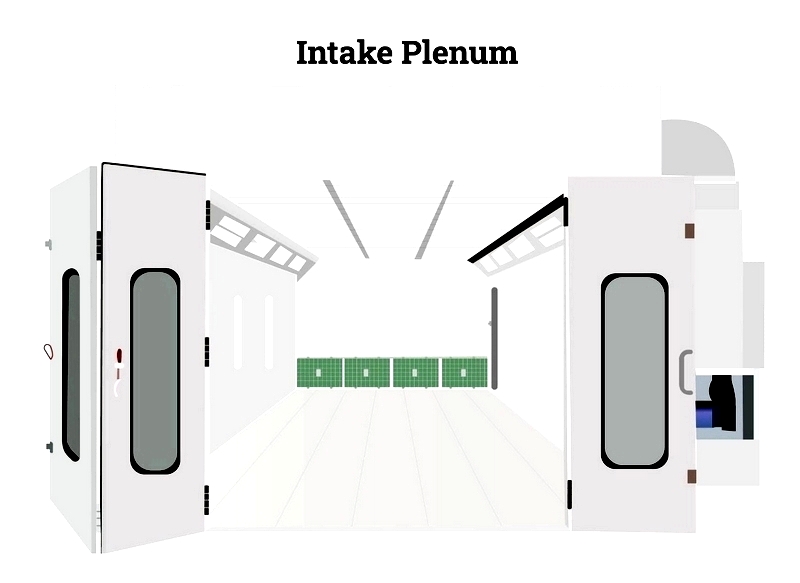

Intake Plenum

The intake plenum in a pressurized booth is located at the front or top, introducing air. Air flows horizontally at floor level or vertically from overhead plenums. High-efficiency filters remove dust and debris before air enters the booth.

The plenum can be arranged vertically at one end or horizontally across part or all of the roof. In cross-draft booths, it's typically at the front.

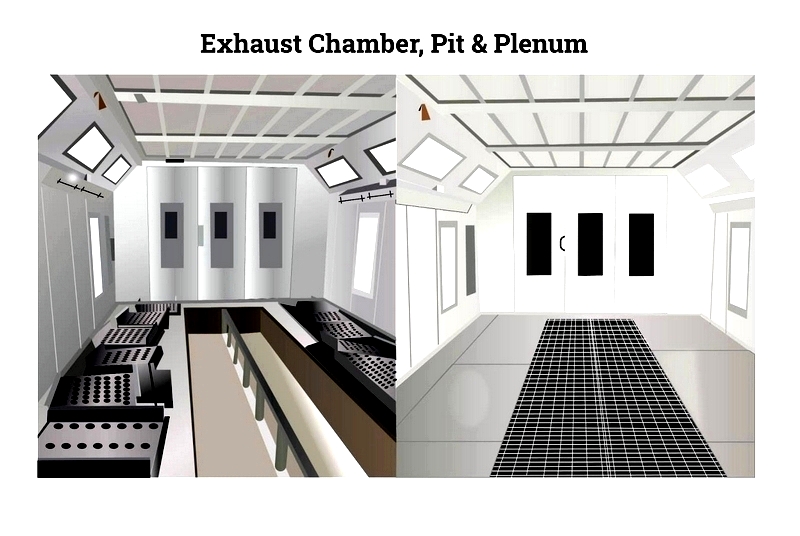

Exhaust Chamber, Pit, and Plenum

The exhaust plenum expels and filters air from the booth. It includes filters to capture particles before releasing air outside. An exhaust fan directs air through filters and ducts.

In cross-draft and semi-downdraft booths, the exhaust plenum is at the back. In downdraft booths, it's along the sides. Air flows downward to the floor and exits through a filtered pit.

Exhaust filters protect fans and plenums from overspray while maintaining airflow efficiency. They are located in the rear plenum, pit, or side downdraft sections.

Multi-layer filters capture paint particles on surfaces and within the medium, extending filter life and reducing costs. Wave booth filters handle various paint types and applications.

Portable booths often use multiple filter banks, including pre-filters, overspray capture filters, and carbon filters, for air recirculation and purification.

Air Make-Up Unit (AMU)

Exhausted air must be replenished. An AMU filters and conditions replacement air drawn from outside.

AMUs regulate booth temperature during painting and curing. They maintain consistent air temperature regardless of external conditions.

These units supply filtered, conditioned air directly to the booth, improving worker conditions and reducing costs.

Paint Booth Manometers

Differential pressure gauges measure exhaust filter loading. Manometers, like Magnehelic gauges, are common in industrial booths.

These gauges indicate dirty filters and monitor airflow, alerting when replacements are needed.

Operating Mechanics of a Spray Booth

Paint booths operate through spraying and drying stages. For safety and ventilation, spraying should be steady. Fresh air enters through an intake ventilator, heats via an exchanger, and filters through the system. It moves through ceiling filters or floor grates in single-inlet setups.

During drying, equipment raises temperatures to 140–158°F (60–70°C). Standard heaters may struggle to reach 158–176°F (70–80°C), but solutions exist. Portable booths filter and recirculate air, maintaining an enclosed environment.

Technical Specifications for Spray Booths

Using flammable liquids in spray finishing increases flammability due to atomization. Proper hazard management prevents fires, employee risks, and property damage. This chapter outlines NFPA-approved design and build standards, detailing key specifications.

Booth Construction and Design Criteria

Specifications include:

- Use non-combustible or limited-combustible materials for walls, doors, and ceilings; ensure sturdy mounting.

- Booth surfaces should be smooth and seamless for easy cleaning without damage.

- Air intake filters must meet ANSI/UL 900 Class 1 or 2 standards.

- Avoid aluminum in structural supports or ductwork.

- Single-skin sheet metal should not exceed 0.05 in (1.2 mm); double skins no thicker than 0.035 in (0.9 mm).

- Isolate bo