Introduction

This is the most comprehensive online guide available about glycol chillers. You will learn:

This article provides an in-depth exploration of glycol chillers, covering topics such as:

- What is a Glycol Chiller

- Types of Glycol Chillers

- Benefits of Glycol Chillers

- The Design of Glycol Chillers

- And much more...

Chapter One – Understanding Glycol Chillers

A glycol chiller is an industrial cooling system that uses a glycol-water mixture to achieve temperatures below water's freezing point. These systems typically use either ethylene glycol or propylene glycol, with the glycol's antifreeze properties preventing coolant solidification at low temperatures. Most chiller systems operate with a 60% glycol to 40% water ratio.

Higher glycol concentrations improve antifreeze performance, enabling faster cooling and better heat transfer efficiency. This precise temperature control is essential for many industrial processes. Glycol chillers circulate coolant through heat exchangers to absorb heat from industrial applications, then return it to the chiller for cooling before reuse. These systems are particularly valuable for maintaining frozen food quality and supporting food processing operations.

Chapter Two – Types of Glycol Industrial Chillers

Glycol, an organic alcohol with excellent antifreeze properties, is widely used in industrial cooling systems. Its superior thermal conductivity makes it ideal for temperature-sensitive industrial processes. Glycol chillers efficiently remove heat to maintain stable conditions in chemical, pharmaceutical, and food processing operations. Beyond temperature control, they prevent equipment overheating and production downtime. These chillers are indispensable in brewing, dairy processing, plastics manufacturing, medical device production, and HVAC systems where reliable heat exchange is critical.

There are two main glycol types: ethylene glycol and propylene glycol. While both are effective, they differ in toxicity, fluid properties, and heat transfer performance. Mixing them is not recommended as it can cause system inefficiencies or corrosion. The choice between them depends on safety requirements, process compatibility, and regulatory standards.

Ethylene and Propylene Glycol Chillers

Ethylene (EG) Glycol

Ethylene glycol is a highly efficient industrial coolant with excellent heat transfer and antifreeze properties. It's commonly used in industrial cooling systems, process chillers, and closed-loop refrigeration for freeze protection and temperature stability. The optimal concentration depends on expected temperatures and process requirements. With a 240°F flashpoint and broad chemical compatibility, it's suitable for HVAC systems, plastics manufacturing, and chemical processing. However, its toxicity makes it inappropriate for food or pharmaceutical applications.

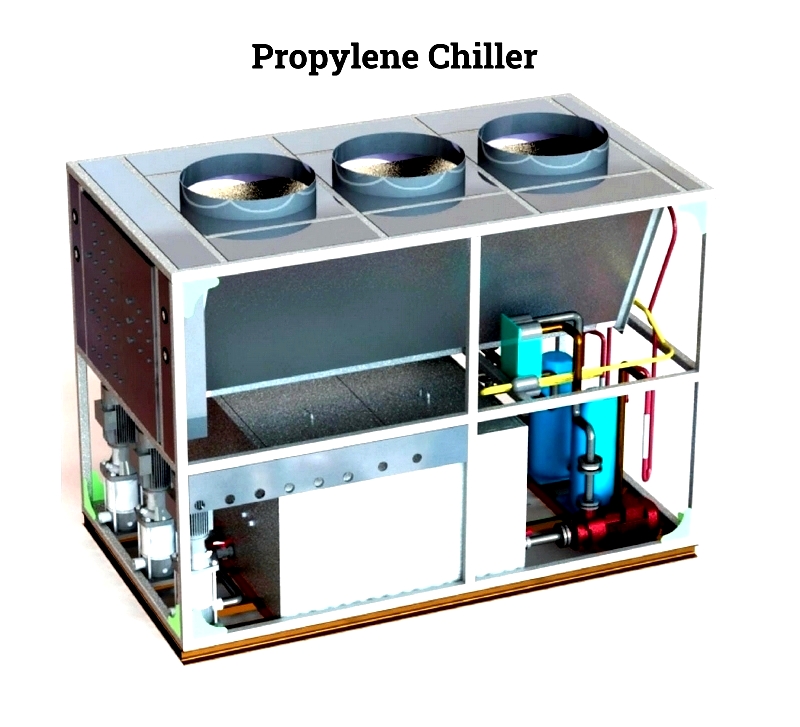

Propylene (PG) Glycol

Propylene glycol is a low-toxicity alternative ideal for food-grade applications. Its safety profile makes it preferred for food processing, breweries, and pharmaceutical cooling. FDA-approved for food contact, it provides efficient heat transfer without health risks. This biodegradable compound also offers excellent corrosion protection, extending equipment life in demanding environments.

Glycol Industrial Chiller Types

Portable Glycol Industrial Chillers

Portable glycol chillers are compact, mobile units with integrated refrigeration components. With capacities from 1 to 40 tons, they're ideal for labs, pilot plants, and small-scale production. Their modular design allows easy relocation and customization for specialized applications.

Modular Glycol Industrial Chillers

Modular systems offer scalable, redundant cooling for industrial processes. Multiple parallel-connected modules allow capacity expansion to meet growing demands. Features include oversized pumps, insulated reservoirs, and expansion ports. These systems maintain operation during maintenance or failures, making them ideal for critical industries. Energy efficiency is optimized by running only necessary modules.

important Facts about Glycol Industrial Chillers

Key considerations when selecting glycol chillers include performance, compatibility, and maintenance. Modern chillers offer energy efficiency and reliable cooling for temperature-sensitive industries.

- Glycol chillers use precision-engineered coolant mixtures for optimal heat transfer and freeze protection.

- Glycol is an alcohol derivative with antifreeze and corrosion-resistant properties.

- Standard 60/40 glycol-water ratios can be customized for specific applications.

- Ethylene glycol suits industrial uses; propylene glycol is for food/pharmaceutical applications.

- Ideal for food/beverage production, brewing, and dairy processing.

- Designed to resist corrosion and microbial growth.

- Provide precise temperature control for quality assurance.

- Enhance food quality through rapid, uniform chilling.

- Advanced designs achieve ultra-low temperatures for demanding applications.

- Modern chillers incorporate eco-friendly features and energy-saving technologies.

When purchasing, consider capacity, efficiency, temperature range, compressor type, cooling method, and lifecycle costs. Manufacturers offer customized solutions and support to meet specific requirements. Understanding your application's needs ensures optimal chiller selection and long-term reliability.