Introduction

Discover everything you need to know about hydraulic lifts.

You'll learn about:

- The fundamentals of hydraulic lifts

- How hydraulic lifts operate

- Different types of hydraulic lifts

- Hydraulic lift tables

- And much more...

Chapter One – Understanding Hydraulic Lifts

A hydraulic lift is a device that raises objects using force created by liquid pressure in a cylinder, causing the piston to move upward. When incompressible oil enters the cylinder, it lifts the piston. Opening a valve to release the oil allows the piston to descend under gravity's force.

Hydraulic lifts function based on Pascal's Law, which states that pressure changes in an enclosed incompressible fluid are transmitted equally in all directions throughout the fluid.

This principle can be demonstrated when a small force applied to one end of a hydraulic system creates a much larger force at the opposite end.

Hydraulic systems offer precise control for high-force applications, cost-effectiveness, and energy efficiency.

Chapter Two – How Hydraulic Lifts Work

Hydraulic lifts operate on hydraulic principles, using Pascal's Law to amplify force. The system applies force to incompressible hydraulic fluid (typically high-grade oil), transferring it through pipes to create lifting or moving power. The mechanism features two connected pistons—the master and slave cylinders—joined by reinforced hydraulic lines filled with oil.

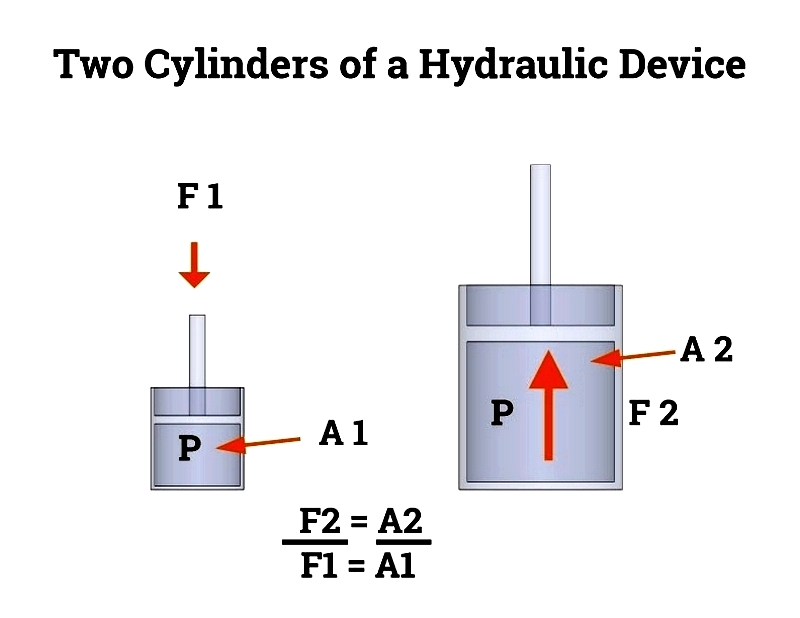

The following image shows these pistons connected by a pipe.

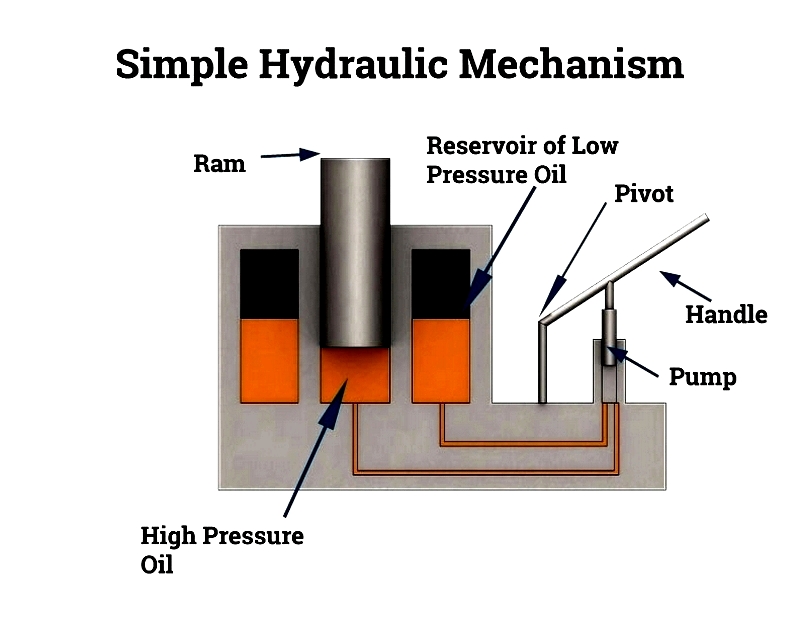

This diagram illustrates a basic hydraulic mechanism. The right handle pumps oil from the reservoir into the central high-pressure chamber, causing the ram to rise.

Force Generation in Hydraulic Lifts

Hydraulic lift force depends on piston surface area. Pascal's Principle explains how pressure applied to a small input piston transfers through fluid to a larger output piston, multiplying force. For instance, a two-inch diameter input piston can lift nine times more weight than the force applied. This explains hydraulic lifts' widespread use in auto shops, manufacturing, and material handling.

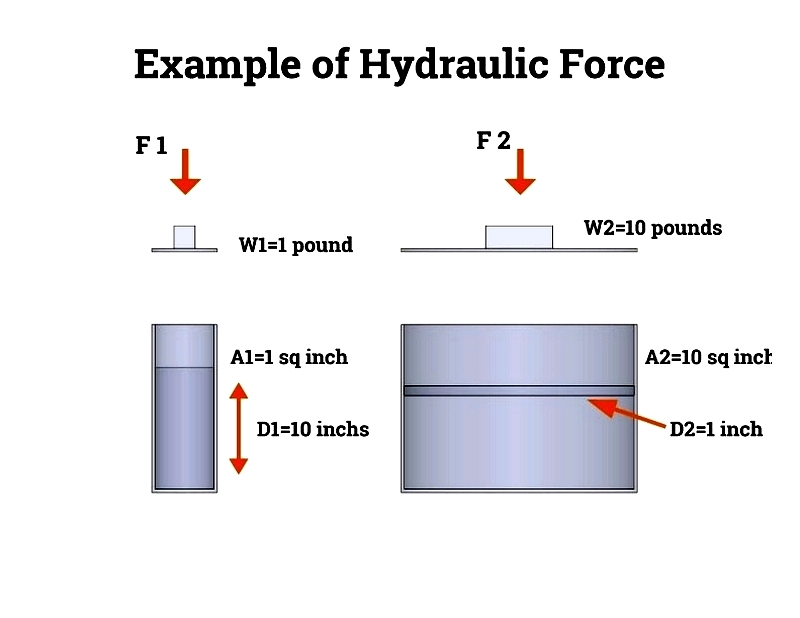

The diagram demonstrates how minimal effort on a small piston can lift substantial weight. A one-pound load on a one-square-inch piston moving down ten inches raises a ten-pound load.

This combination of power and precision makes hydraulic lifts indispensable for automotive, industrial, and accessibility applications.

Key Hydraulic System Components

All hydraulic lifts share common components that ensure performance, safety, and durability. Understanding these parts is essential for proper operation.

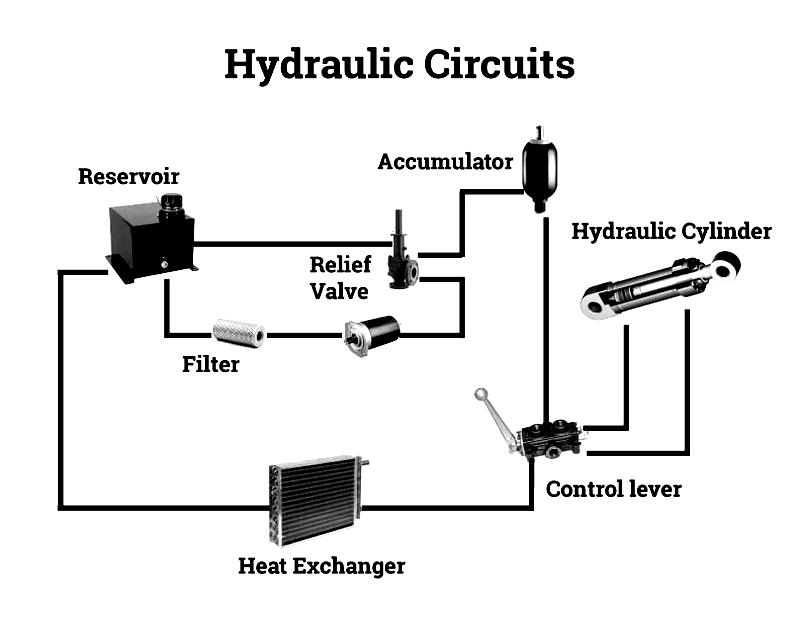

Hydraulic Circuits

These specialized pathways control fluid flow and pressure using valves, switches, and controllers to ensure safe actuator movement. The image below shows typical hydraulic circuit features.

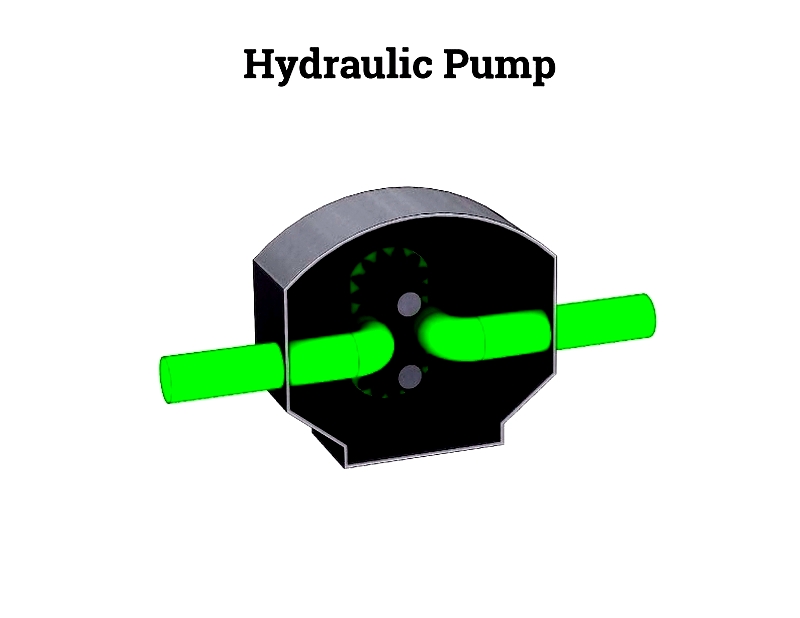

Hydraulic Pump

Converting mechanical power into hydraulic energy, pumps create fluid flow through the system. Proper pump selection (gear, vane, or piston) ensures efficient operation for specific applications.

Hydraulic Motor

These convert fluid pressure into rotational force for continuous motion applications, working with pumps to power industrial equipment.

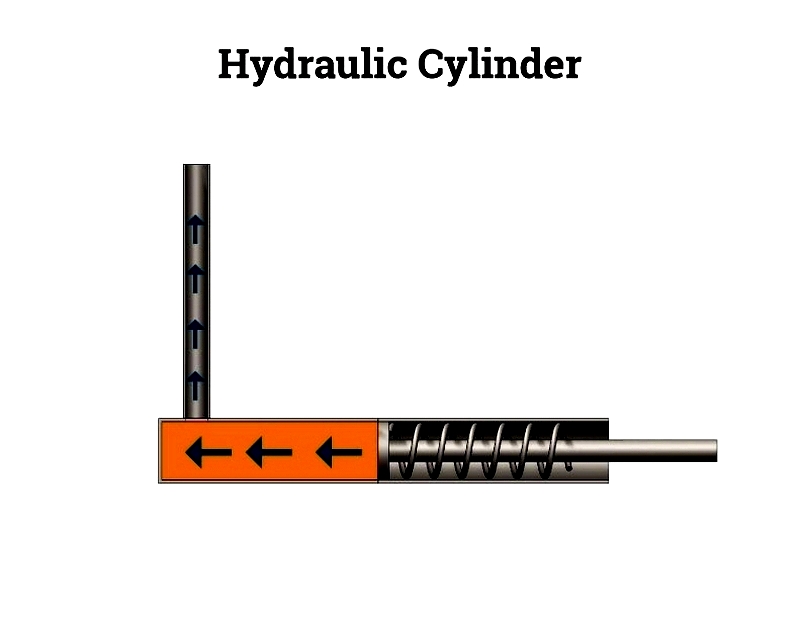

Hydraulic Cylinder

The linear actuator that creates vertical movement in lifts and jacks, available in single or double-acting designs with varying capacities.

Hydraulic Pistons

Operating under high pressure, these provide precise movement, with advanced designs enhancing system responsiveness.

Hydraulic Fluids

Specialized fluids (mineral oils, synthetics, or water-based) ensure proper operation, with selection based on temperature, safety, and environmental needs.

Control Valves and Safety Devices

These critical components manage movement and prevent overpressure, incorporating emergency features for industrial safety.

Hydraulic Lift Advantages

Offering precision, power, and reliability, hydraulic lifts outperform mechanical alternatives in automotive, industrial, and accessibility applications.