Introduction

This article provides an in-depth examination of hydraulic seals.

Key topics covered include:

- Principle of Hydraulic Seals

- Types of Hydraulic Seals

- Applications, Benefits, and Common Failures of Hydraulic Seals

- And Much More...

Chapter 1: Understanding the Principle of Hydraulic Seals

This chapter explores hydraulic seals in detail, analyzing their design and construction while highlighting crucial factors for selecting appropriate seals.

Defining Hydraulic Seals

Hydraulic seals are specialized ring-shaped gaskets designed to fill gaps between hydraulic cylinder components. These seals prevent fluid leakage at connection points. Each seal is custom-designed to fit specific hydraulic cylinder sections, ensuring reliable, leak-free connections.

While O-rings and hydraulic seals share similarities, hydraulic seals feature a distinctive groove on the lip that ensures secure component attachment. This design maintains a leak-tight seal during component movement and effectively contains fluids within the designated chamber, even under increasing piston movement and fluid pressure.

Building Hydraulic Seals

Both manufacturing processes and material selection play vital roles in hydraulic seal construction.

Seals Manufacturing Process

Hydraulic seal production utilizes Computerized Numerical Control (CNC) lathe machines. These precision machines create standard and custom seal profiles by following digital programming instructions to cut seals from selected materials.

Materials Used for Hydraulic Seals

Manufacturers use various materials for hydraulic seals. Rubber offers flexibility, resilience, and crack resistance, while polyurethane provides greater durability and wear resistance with comparable functionality.

Polytetrafluoroethylene (PTFE), though less common, offers pliability, durability, and high-temperature resistance. Material selection depends on operational factors including fluid type, pressure, chemical compatibility, and temperature conditions.

Factors for Selecting Seals

Consider these critical factors when choosing seals:

Shaft Speed Considerations

Maximum shaft speed depends on factors like shaft finish, runout, bore alignment, fluid type, and seal material.

Temperature Tolerance

Operating temperatures must remain within the seal elastomer's specified range.

Managing Pressure

Standard oil seals typically handle low pressures (approximately 8 psi or less). Higher-pressure systems require pressure relief mechanisms.

Hardness of the Shaft

Shafts with Rockwell hardness of 30+ ensure longer seal life. Increase to RC 60 for abrasive environments.

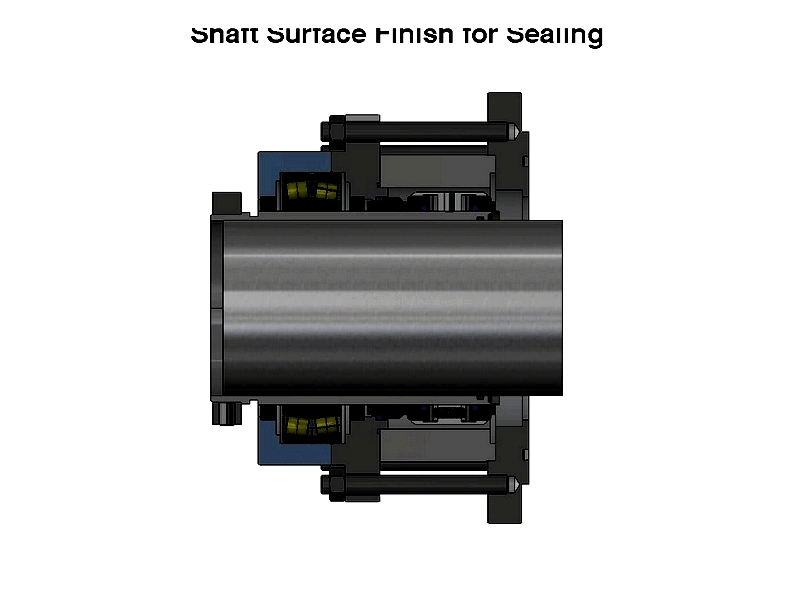

Surface Finish of the Shaft

Superior shaft surface treatments enhance sealing effectiveness. Avoid spiral lead in tool mark finishes; concentric polished or ground finishes work best. If spiral finishes are necessary, align them with fluid flow during shaft rotation.

Seal Alignment (Concentricity)

Misaligned bore and shaft centers cause uneven wear on sealing lips, reducing seal lifespan.

Tolerance Levels of Shaft and Bore

Close alignment of shaft and bore tolerances maximizes seal effectiveness. Consider shaft eccentricity, end play, and vibration.

Minimizing Runout

Keep runout minimal. Wobbling bearings or shaft whip exacerbate misalignment issues, which flexible couplings don't always correct.

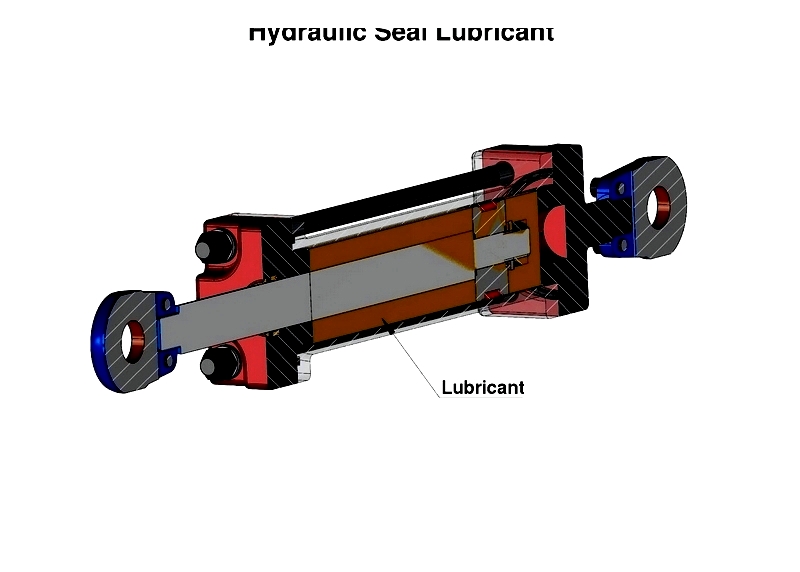

Seal Lubrication

Proper lubrication with compatible viscosity oil enhances seal performance and longevity. Verify seal compatibility with additives and synthetic oils.

Chapter 2: Types of Hydraulic Seals

Hydraulic seals come in various types:

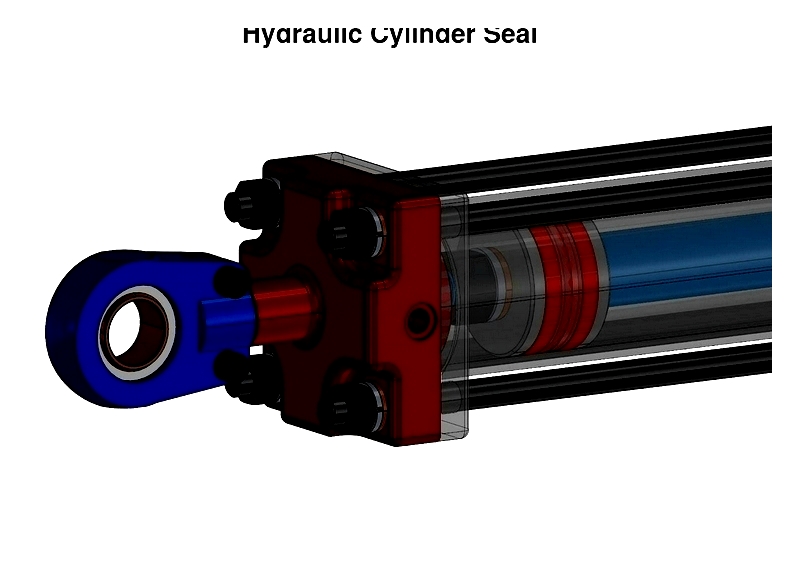

Hydraulic Cylinder Seals

These specialized seals close openings between hydraulic cylinder components. Their advanced designs retain pressurized fluids, block contaminants, and maintain hydraulic pressure. Different seal designs—including rod seals, piston seals, and wiper seals—address diverse operating conditions in construction equipment, manufacturing machinery, and industrial automation systems.

Effective seals conform to metal surface irregularities and adjust to fluctuating clearance gaps. Materials require appropriate modulus and hardness to resist high-pressure shear stress and prevent extrusion.

Seals must contain hydraulic fluids while excluding contaminants that cause equipment wear. Selection depends on whether applications require static seals for stationary joints or dynamic seals for moving parts. High-performance cylinder seals minimize leaks and extend system life, reducing downtime in heavy machinery.

Common questions address material selection for aggressive fluids, service intervals, and failure detection—topics covered in manufacturers' guidance.

Lip Seal

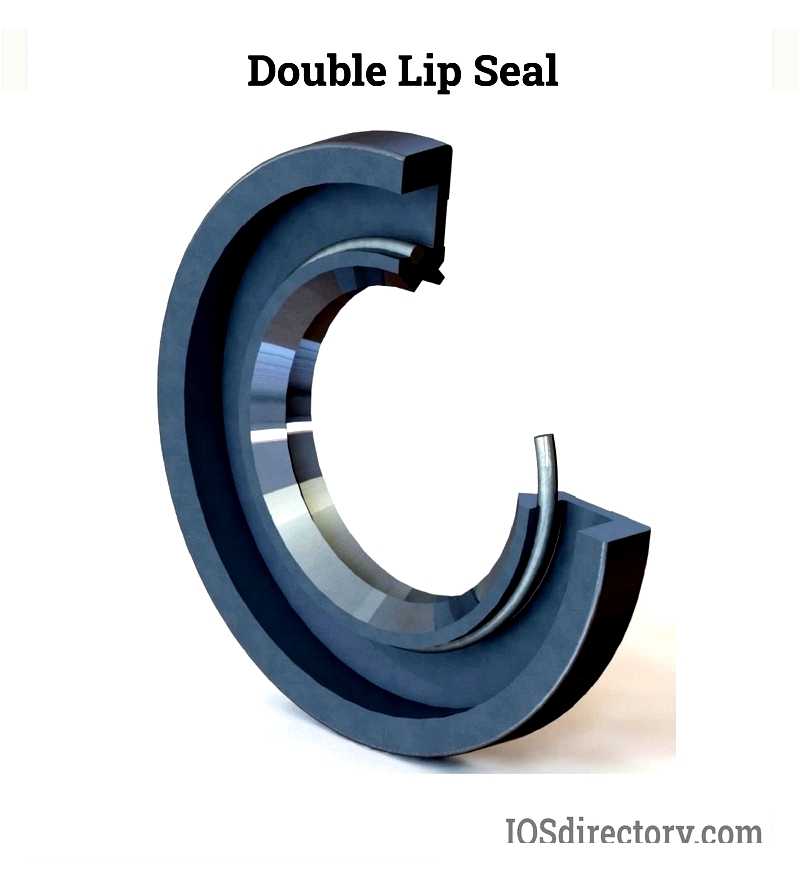

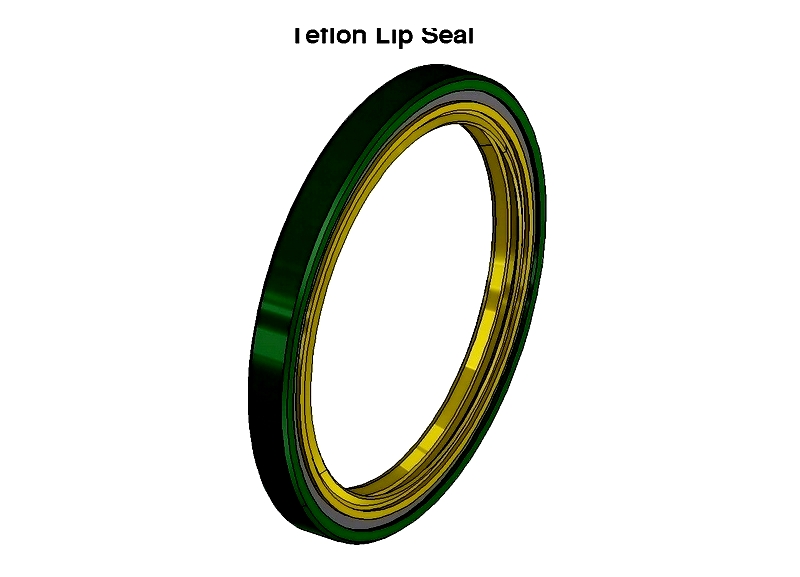

Lip seals feature application-specific designs with pronounced "lips" in radial, rotary, and linear shaft assemblies.

These seals function as barriers and dynamic pumps in systems with rotating, reciprocating, or oscillating shafts. They retain lubricants, exclude contaminants, maintain pressure, and separate fluids in hydraulic cylinders, industrial pumps, and heavy machinery.

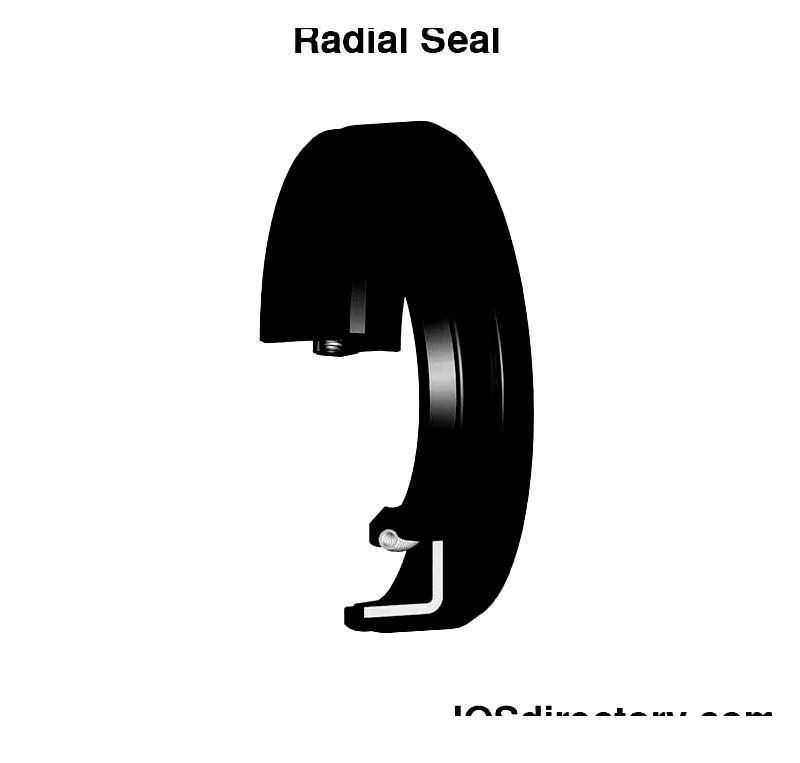

Radial Seals vs Rotary Seals

While wiper scraper seals incorporate lips, industrial terminology varies regionally. US terminology favors "radial seals" for spring-energized designs, while Europe prefers "rotary seals" for rotating shaft applications.

Proper seal selection prevents leakage and premature wear. Modern rotary seals also serve demanding linear applications, requiring specialized lip geometries and materials like PTFE or FKM.

Purpose of Lip Seals

Lip seals block contaminants while retaining lubricants. They operate across wide speed and temperature ranges. Initial leaks may occur until the material beds into the shaft surface.

Lip Seal Design

From leather straps to modern elastomers, lip seal evolution has expanded their applications. Current designs include economical non-spring seals for low-speed applications and spring-loaded seals for high-speed, high-pressure systems.

Mechanical Seal

These critical components prevent leaks in rotating equipment like pumps and compressors, particularly in high-pressure hydraulic systems and chemical plants.

Seal assemblies feature stationary and rotating faces. Design variations accommodate fluid type, pressure, temperature, and shaft speed. Proper selection maximizes uptime and efficiency while minimizing failure risks.