Introduction

This article covers everything you need to know about electromagnetic coils and their applications.

You'll learn about:

- What electromagnetic coils are

- Different types of electromagnetic coils

- How electromagnetic coils function

- Key components of electromagnetic coils

- And much more...

Chapter 1: What is an Electromagnetic Coil?

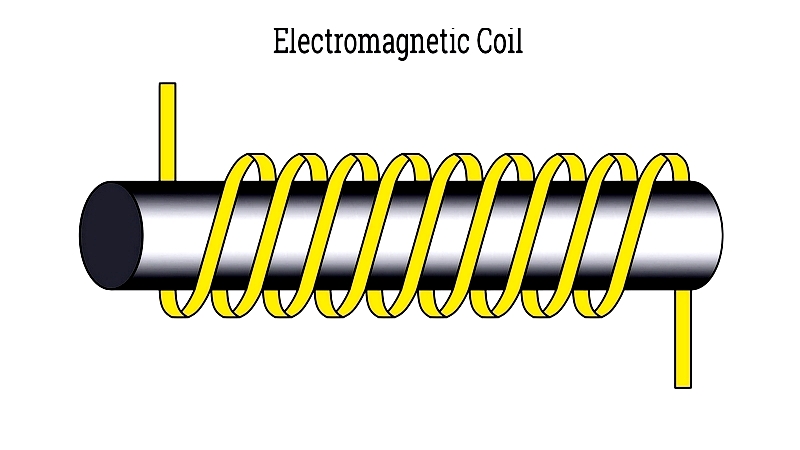

An electromagnetic coil is a crucial electrical component that generates an electromagnetic field when current flows through it. Typically made of wire wound around a core, these coils can have cylindrical, bobbin, or oval shapes. The core material varies and may include metal, plastic, or even air. As current passes through the wire, the coil performs various specialized functions.

Most electromagnetic coils use copper or aluminum wire wound around ferromagnetic cores like iron, nickel alloys, or cobalt. These materials enhance magnetization, increasing the coil's electromotive force (EMF) and magnetic flux. A ferromagnetic core boosts magnetic flux density, amplifying the coil's magnetic field.

These coils play vital roles in electrical circuits, enabling control of high-power circuits using lower-energy circuits. Transformers, for example, use electromagnetic coils to transfer energy between circuits through electromagnetic induction.

Chapter 2: Types of Electromagnetic Coils

Electromagnetic coils are fundamental in electrical engineering, created by winding conductive wire (usually copper or aluminum) into coils, spirals, or helices around a core. When current flows through the wire, it produces a magnetic field via electromagnetic induction. These coils (also called inductors) are essential in modern electronics, industrial machinery, and power systems, serving functions like energy storage, signal filtering, and magnetic field generation.

Solenoid

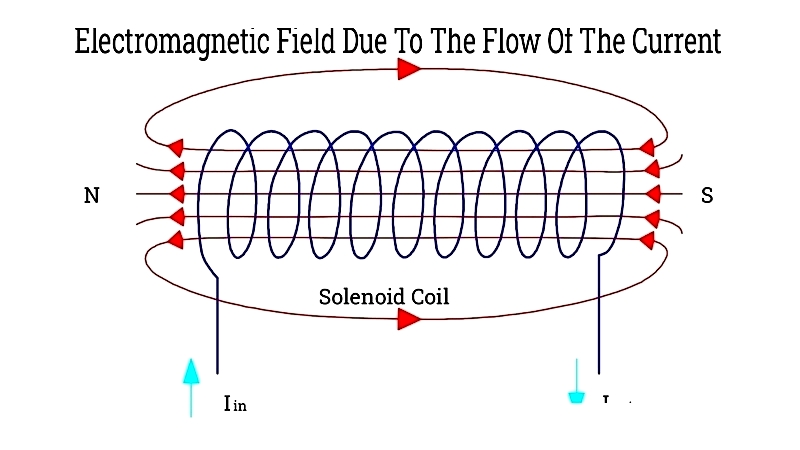

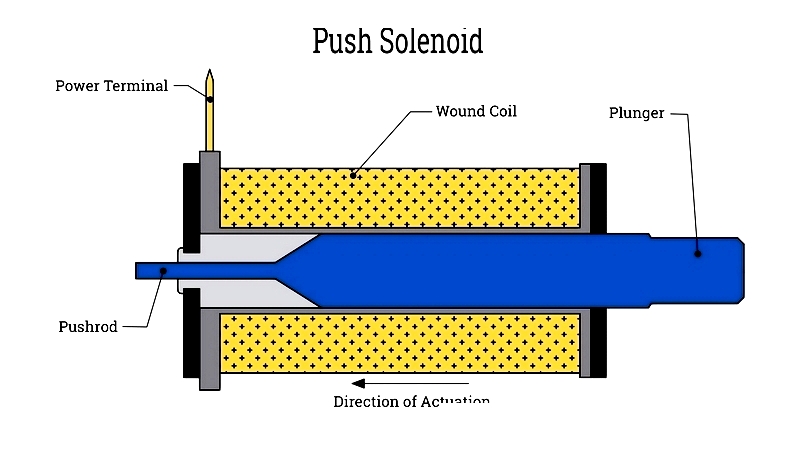

A solenoid consists of tightly wound wire around a cylindrical core, forming a helix. When energized, it generates a uniform magnetic field, making it effective as an electromechanical actuator. Solenoids convert electrical energy into linear motion by attracting a movable plunger, commonly used in valves, locks, and relays.

When current flows through a solenoid, the magnetic field pulls a rod inward. When de-energized, the rod returns to its original position. Despite their simplicity, solenoids are crucial in many mechanisms.

Toroidal Electromagnetic Coils

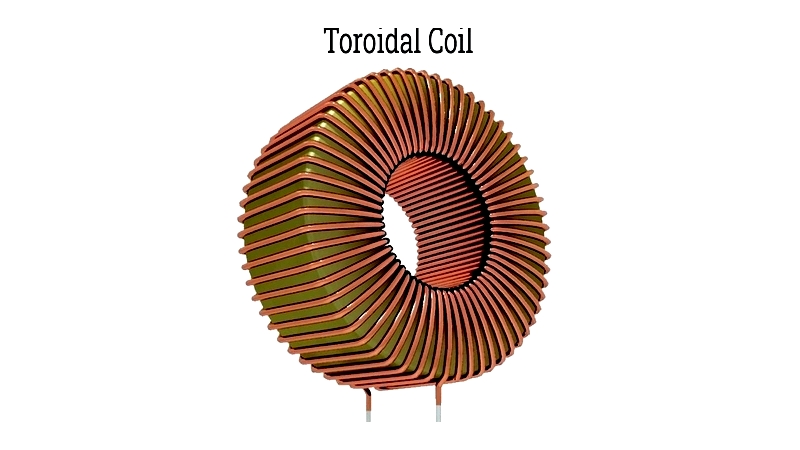

Toroidal coils have a donut-shaped design with a closed-loop core. This configuration confines the magnetic field within the core, minimizing leakage and electromagnetic interference (EMI). Made from ferromagnetic materials like iron or ferrite, these coils are efficient for energy transfer and reduce interference from other components.

Their high efficiency and compact size make them ideal for sensitive electronics, telecommunications, and power supplies. When selecting toroidal coils, consider inductance, core material, and wire gauge for specific applications.

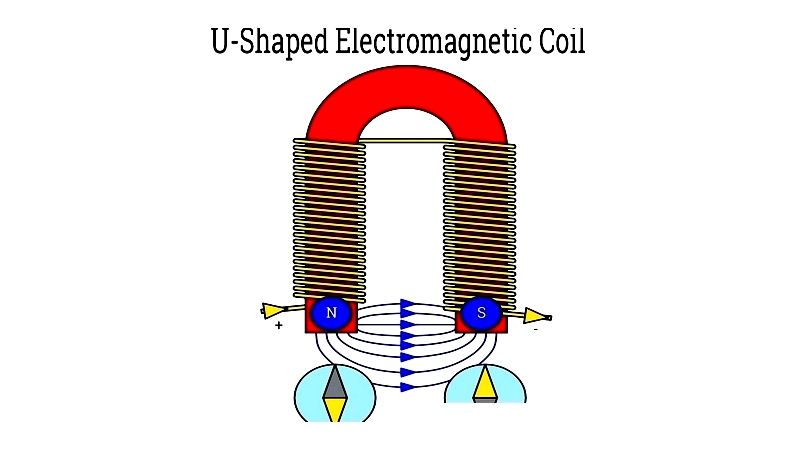

U-Shaped Electromagnetic Coils

U-shaped coils feature two excitation coils at each end of a U-shaped ferromagnetic core. The magnetic field concentrates at the poles, creating strong, directed fields for lifting or holding applications. These coils typically use iron or magnetic alloy cores with insulated copper or aluminum windings.

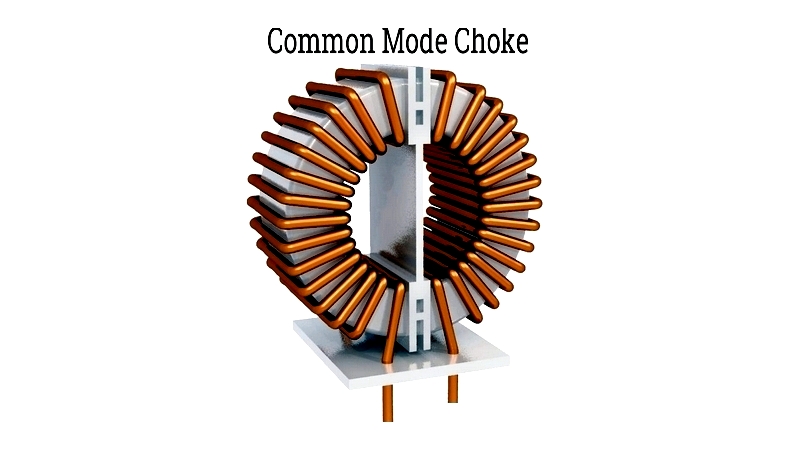

Choke Electromagnetic Coil

Choke coils block high-frequency AC while allowing DC or low-frequency AC to pass. They're essential in power supplies and RF equipment for noise suppression. In DC applications, they filter ripples for steady output. For RF, they block all but DC current.

Chokes are categorized as audio chokes (blocking power line frequencies) or radio chokes (blocking RF while passing audio/DC). When choosing chokes, consider current rating, frequency response, and core material.

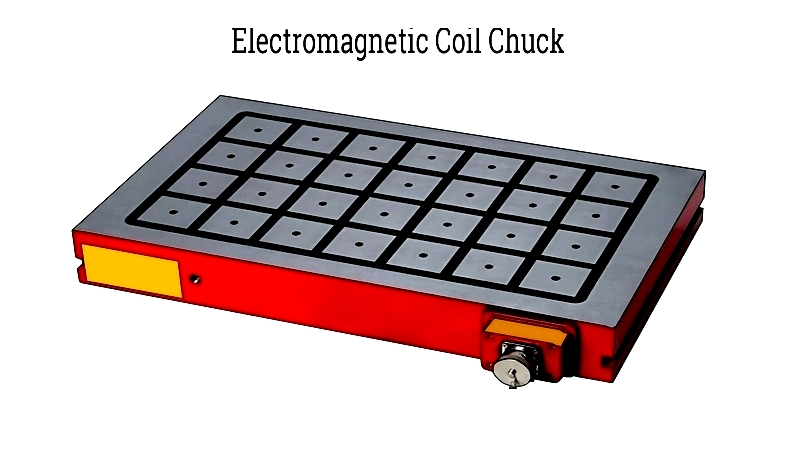

Electromagnetic Coil Chuck

These specialized clamps use embedded coils to generate holding force for workpieces in machining operations like grinding and milling. The chuck's surface has magnetic poles for even force distribution, with current control for precise clamping. They're used in grinding ferromagnetic materials and precision machining.

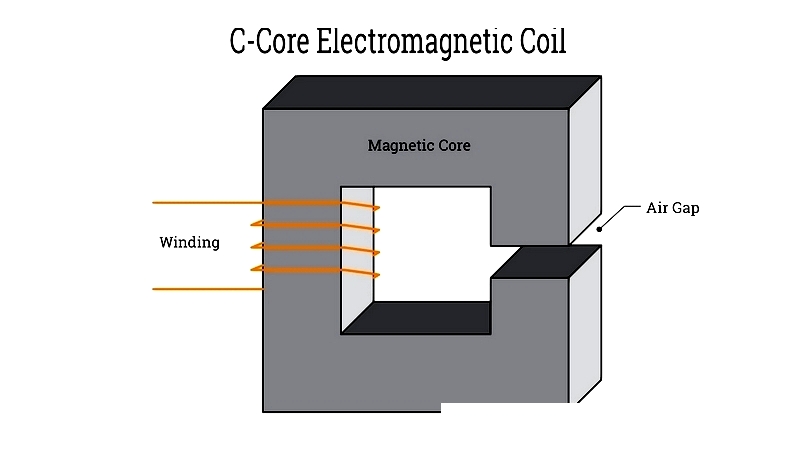

C-Core Electromagnetic Coil

C-core coils intensify magnetic fields at their ends, where the gap between poles is located. The air gap increases magnetic flux resistance, creating stronger fields at the poles. These coils are used in power electronics for compact, open magnetic circuits.

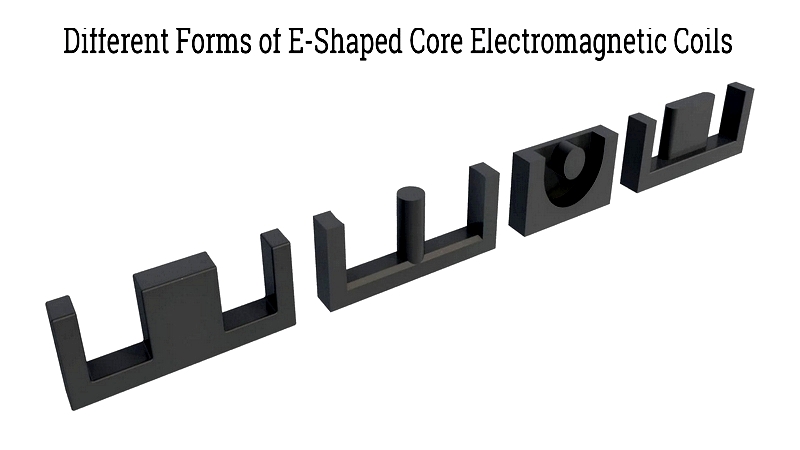

E-Shaped Electromagnetic Coils

E-shaped coils have a central leg for winding, with various shapes like cylindrical or rectangular. Their air gaps make them suitable for switching regulators and power inductors, though they suffer from high leakage. Despite this, they're popular for their affordability and easy assembly.

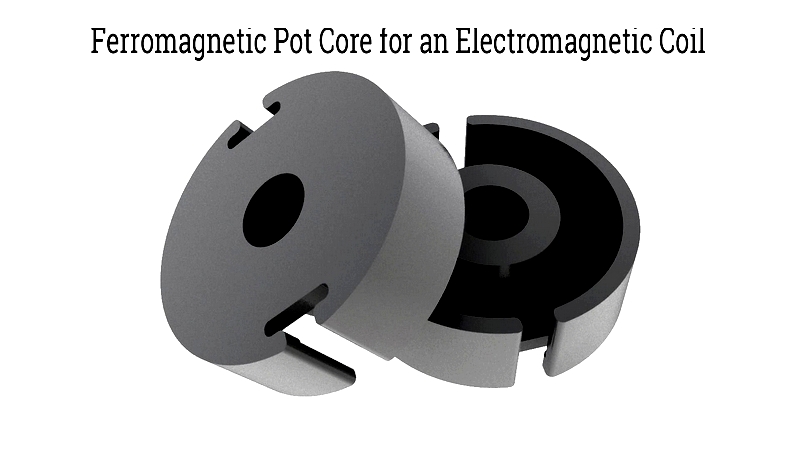

Potted Electromagnetic Coil

Potted coils are encapsulated in protective materials like epoxy or silicone for insulation against moisture, vibration, and EMI. This makes them reliable for harsh environments. They're used in power transformers and telecommunications equipment.

Helmholtz Electromagnetic Coil

Helmholtz coils generate uniform magnetic fields for scientific research and testing. Two identical, parallel coils create a controlled field in their central region. They're used in physics experiments and sensor calibration.

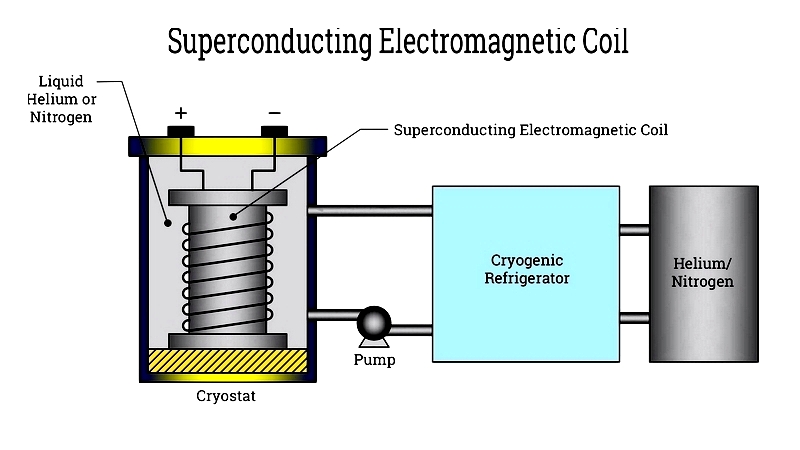

Superconducting Electromagnetic Coils

These advanced coils use niobium-titanium or niobium-tin alloys that exhibit zero resistance at cryogenic temperatures. They support high currents and generate intense magnetic fields, making them ideal for MRI machines and particle accelerators.

Bobbin Coils

Bobbin coils feature precise wire winding around a ferromagnetic core for consistent performance. They're compact and efficient, used in power supplies, relays, and audio electronics. When selecting, consider inductance, core material, and current rating.