Introduction

This article provides an in-depth exploration of linear motion products.

It covers detailed information on topics including:

- Principles of Linear Motion Products

- Types of Linear Motion Products

- Considerations When Selecting Linear Motion Products

- Applications and Benefits of Linear Motion Products

- And More...

Chapter 1: Core Principles of Linear Motion Products

This chapter examines the fundamental principles of linear motion products and explains how linear actuators operate.

Understanding Linear Motion Products

High-precision linear motion components are essential in industries like machine tools and semiconductor manufacturing. These components enable straight-line movement while minimizing friction. Manufacturers have developed advanced bearings using various methods to reduce sliding friction.

Linear actuators convert motor rotation into linear displacement. Unlike standard electric motors that rotate, linear actuators produce forward and backward motion. This reciprocating action allows for smooth sliding, tilting, and lifting. The design provides precise control for production tasks. Linear actuators are energy-efficient due to their smooth operation and require minimal maintenance. They are also more cost-effective, compact, and easier to install than hydraulic or pneumatic systems.

Fundamentals of Linear Motion

While not all linear motion projects require full theoretical understanding, familiarity with these concepts helps create reliable and cost-effective designs.

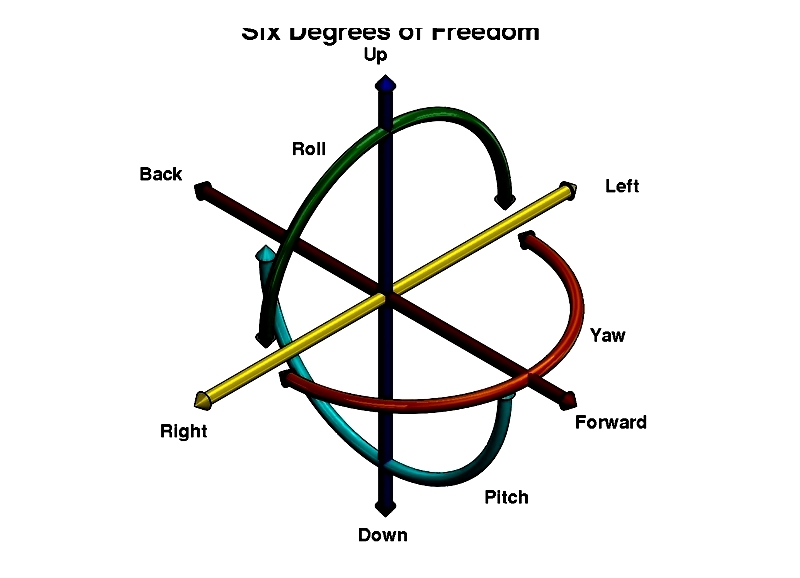

Degrees of Freedom

Some multi-axis systems offer six degrees of freedom and support over seven motion axes. It's important to distinguish between "axes of motion," which describe movement in Cartesian coordinates, and "degrees of freedom," as shown below.

Cartesian and Polar Coordinate Systems

Cartesian coordinates are primarily used for linear motion, though polar coordinates may be employed in applications like articulated robots.

Moment and Torque

Moments or torques result from forces applied at a distance. The key difference is that moments are static, while torque causes rotational movement.

Yaw, Pitch, and Roll

These terms describe rotational effects based on a component's axis of rotation. Such forces can cause deflection and movement issues in linear guides.

Hertz Contact Stresses

When curved surfaces press together, they create small contact areas that generate Hertz contact stresses. These stresses significantly affect bearing load capacity and lifespan (L10 life).

Ball Conformity

The fit between balls/rollers and raceways influences contact area position and shape. Understanding ball conformity is crucial as it directly impacts Hertz contact stress.

Differential Slip

Load-bearing balls or rollers that slip instead of roll experience differential slip due to elliptical contact areas and varying velocities. This affects friction, heat, and bearing longevity.

Tribology: Wear, Lubrication, and Friction

Friction, reduced by lubrication, primarily causes wear and can lead to bearing failure. Tribology studies the complex relationship between wear, lubrication, and friction.

Stress and Strain

Load-induced tension and compression create stress and strain in materials. These factors are critical for components like fasteners, which may reach yield or tensile limits before showing other signs of wear.

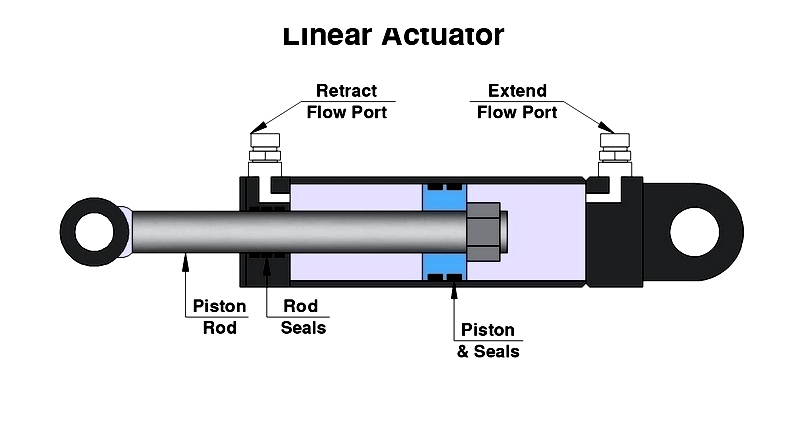

The Functioning of Linear Actuators

Linear actuators move objects or machinery with high precision and repeatability. They transform rotary motion into linear motion, which is essential when adapting rotary-driven sources for linear applications.

They achieve this conversion through mechanical linkage. Most standard electric motors rotate, with couplings or belts connecting them to actuators. This connection allows motor orientation parallel or perpendicular to the actuator, with motor sizes matched to application requirements.

In addition to rotary bearings for components like lead screws or belt pulleys, linear actuators incorporate linear bearings to support moving loads. This design enables standalone operation, simplifying integration into existing systems without costly custom parts.

Linear actuator systems can be enhanced for greater load capacity and stability by pairing them with load-moving setups, such as X,Y gantry systems. Actuators in such configurations are typically synchronized via shafts or belts.

Chapter 2: Types of Linear Motion Products

This comprehensive chapter explores major linear motion product categories, their variations, and practical applications in automation, manufacturing, robotics, and precision engineering. Learn how different components are classified and used to optimize machinery efficiency, accuracy, and productivity across industries.

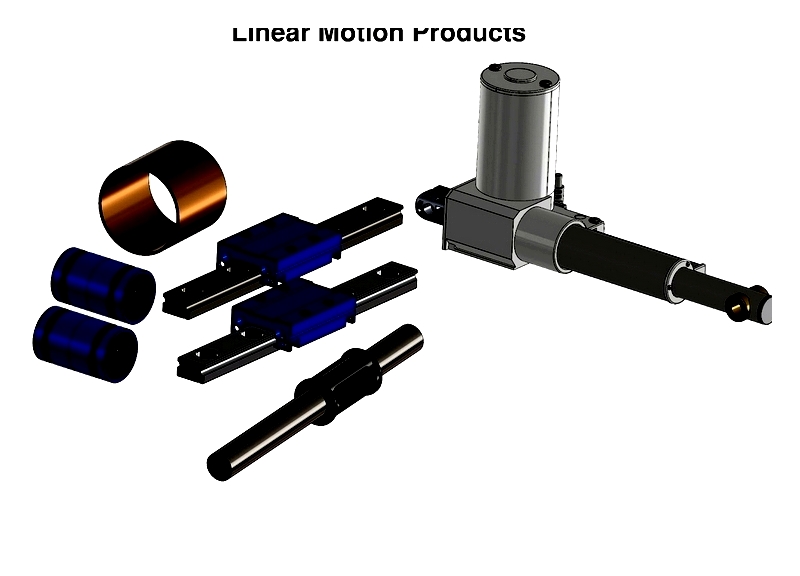

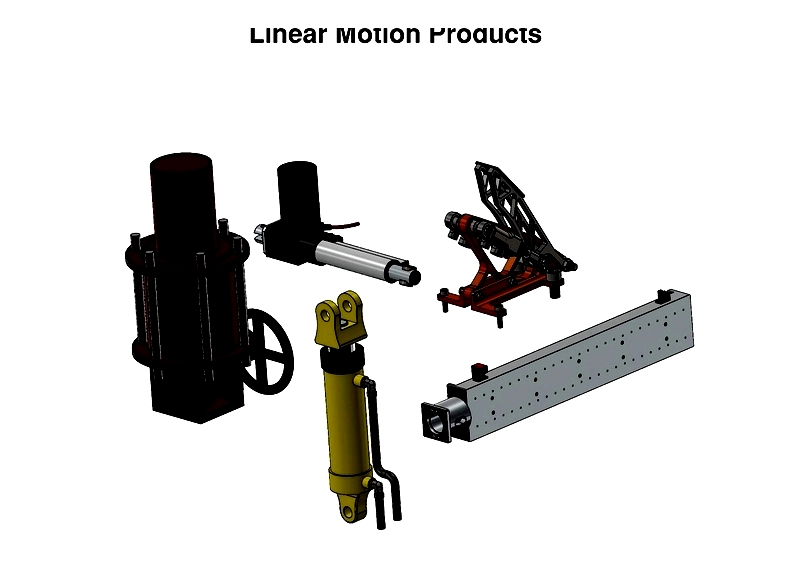

Linear Actuators

Linear actuators are fundamental motion control components that convert energy—mechanical, pneumatic, hydraulic, or electrical—into controlled linear movement. Below are the main types and their industrial applications.

Lead Screw Actuators

These actuators use a simple screw and nut mechanism to convert rotation into linear motion. Common drive sources include manual operation or AC induction motors, suitable for less precise, cost-sensitive applications. Compared to ball screws, lead screws are less efficient and have limited back-driving capability, which can be advantageous for maintaining position when stationary. They're often used in agricultural equipment, manual lifts, and lab automation where safety and reliability outweigh precision needs.

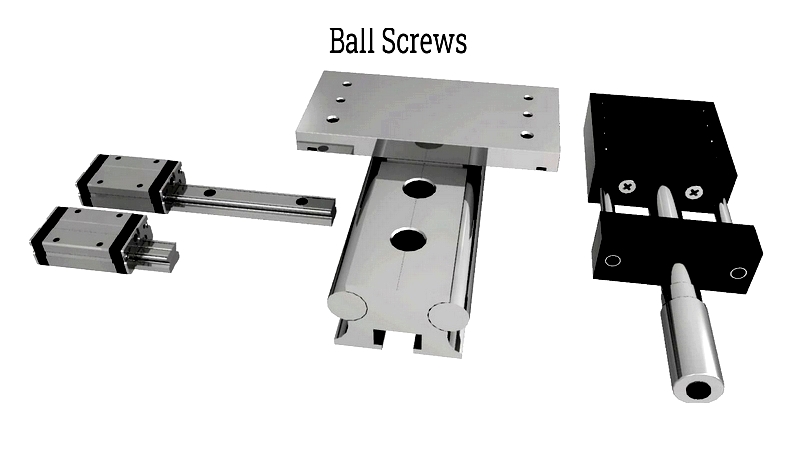

Ball Screw Actuators

These employ precision nuts with ball bearings that roll along threaded screws, similar to ball bearing races. This design offers high accuracy and low friction for efficient motion conversion. Typically driven by stepper or servo motors, they're ideal for rapid, repetitive motion in CNC machines, 3D printers, semiconductor manufacturing, and medical devices.

Belt Actuators

In these systems, a carriage attaches to a belt looping around two pulleys. Motor-driven belt rotation moves the carriage along the actuator. The motor usually mounts perpendicular to the actuator, connecting via flexible coupling.

Belt-driven actuators are cost-effective for simple linear motion applications requiring long travel distances and high speeds, such as packaging, pick-and-place robotics, labeling machines, and material handling systems.

Hydraulic Actuators

Common in high-force valve operations like large steam systems, piston-type hydraulic actuators are most prevalent. They consist of a stem, hydraulic lines, piston, spring, and cylinder. The piston moves vertically, creating upper (spring) and lower (hydraulic fluid) chambers.

Fluid entering the lower chamber creates pressure that opposes the spring force. When hydraulic force exceeds spring force, the piston rises, opening the valve. Fluid removal reverses this process. These actuators excel in heavy-duty applications like foundries, presses, and mobile machinery requiring high force density and durability.

Pneumatic Linear Actuators

Available in piston or diaphragm types, these use compressed air to generate motion. Their safety and ease of air compression make them popular in industrial manufacturing for automated assembly, food processing, and factory automation where rapid, repeatable actuation is needed.