Introduction

This article provides an in-depth examination of open versus closed die forging.

Key topics covered include:

- Principles of Open vs Closed Dies

- Open and Closed Die Forging Processes

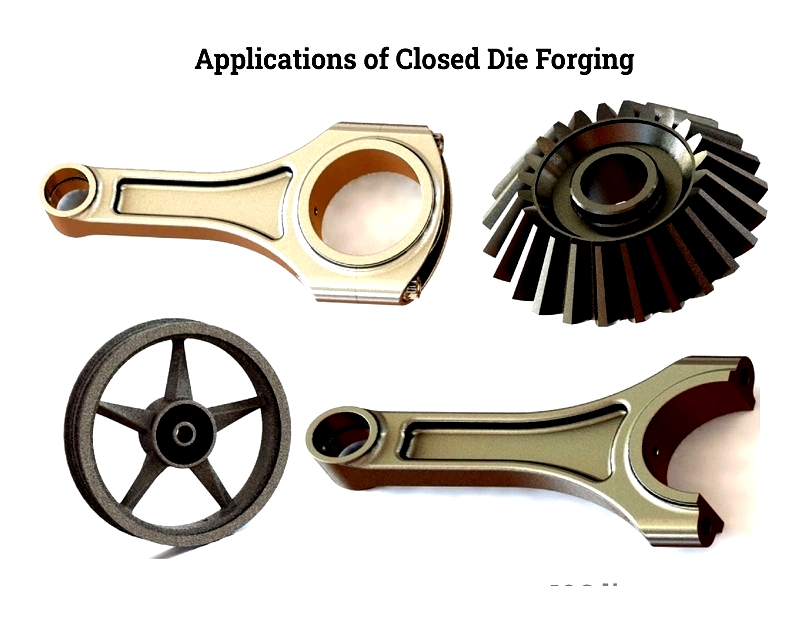

- Applications and Advantages of Both Methods

- Additional important Considerations

Chapter 1: Fundamental Differences Between Open and Closed Die Forging

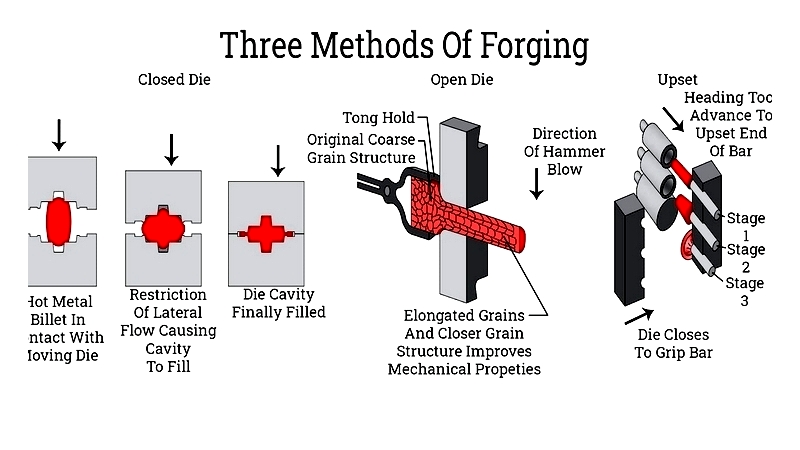

This section explores the various techniques used in open and closed die forging, examining their applications across diverse manufacturing scenarios.

Key Terminology

We highlight essential terms related to open and closed die forging, emphasizing their importance for comprehensive understanding.

Forging Defined

Forging is a manufacturing process where metal is shaped through compressive forces using pressing, hammering, or rolling techniques, creating various forms and patterns.

Forged components come in numerous shapes and sizes, including disks, blanks, rings, bars, and shafts. The schematic below outlines the forging process steps, with detailed explanations in subsequent chapters.

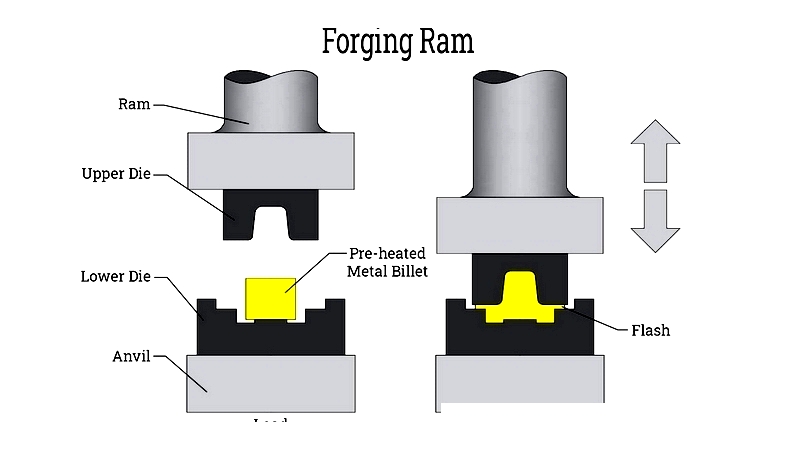

Step 1: Workpiece Positioning

The process begins with precise placement of the workpiece on the lower die. Accurate positioning is critical as adjustments become difficult once forging commences.

Step 2: Die Application

The upper die presses down on the heated workpiece, shaping it according to the die configuration. Elevated temperatures ensure sufficient malleability for efficient forming.

Step 3: Cooling and Finishing

After cooling, the upper die is removed, revealing the forged component ready for various applications.

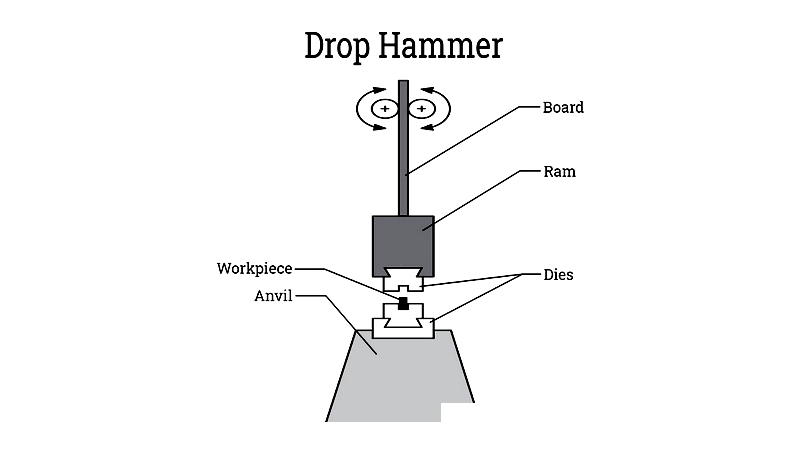

Forging Ram Function

The ram controls vertical movement of the upper die, providing necessary force for workpiece deformation.

Die Characteristics

Dies are specialized tools designed to shape materials into specific profiles through compressive forces.

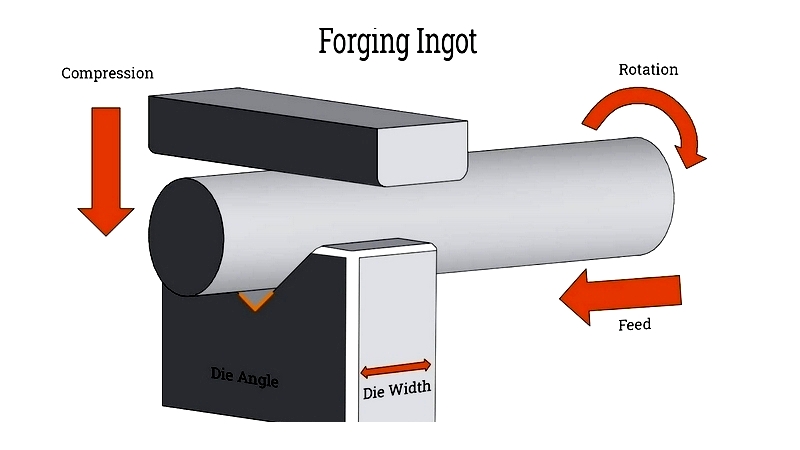

Ingot Definition

An ingot is a metal block, typically rectangular or square, made from materials like steel or precious metals.

Grain Flow Explanation

Grain flow describes the alignment of metal grains during forging, indicating material orientation.

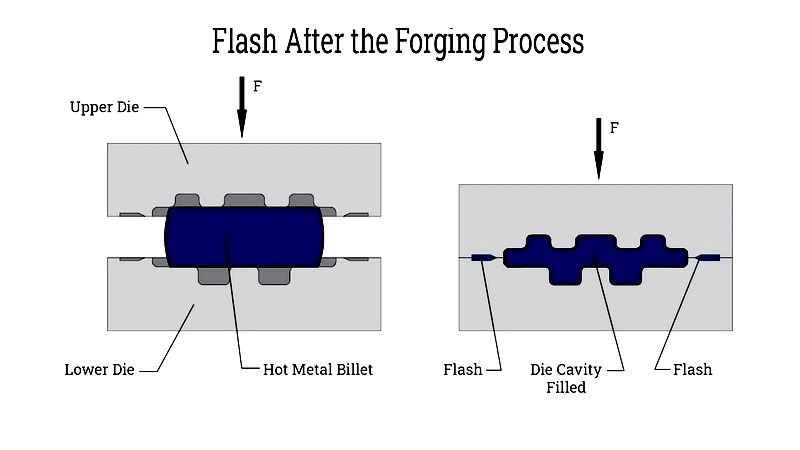

Flash Formation

Flash refers to excess material extruded during forging, typically removed in post-processing.

Forging Hammer Operation

Forging hammers deliver rapid, repeated strikes to shape heated metals through mechanical or electrical power.

Forging Press Purpose

Forging presses apply controlled pressure to shape materials or extract liquids.

Anvil Usage

Anvils provide a stable surface for hammering and shaping metal components.

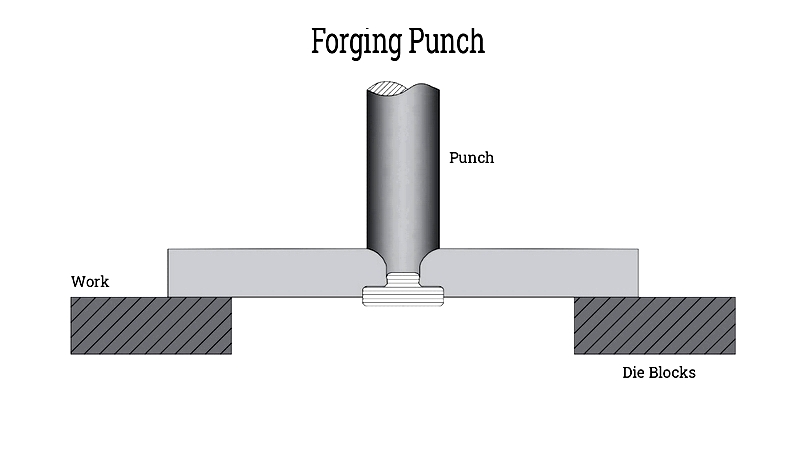

Forging Punch Application

Punches create or expand holes in forged components, available in various configurations.

Chapter 2: Distinguishing Open Die from Closed Die Forging

This chapter examines the critical differences between these forging methods, their industrial applications, and selection criteria for optimal results.

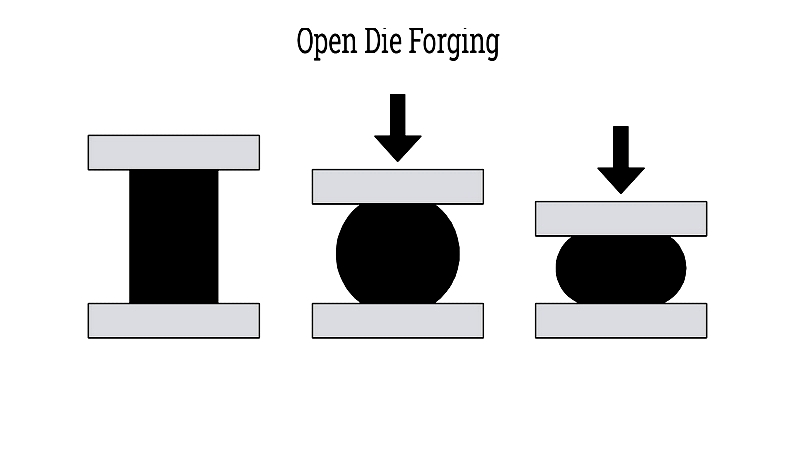

Open Die Forging

Open die forging shapes metal between simple dies without complete enclosure, relying on operator skill for final form. Modern versions use computer controls for enhanced precision.

Process Overview

This hot forming method accommodates various sizes through controlled deformation, optimizing material properties.

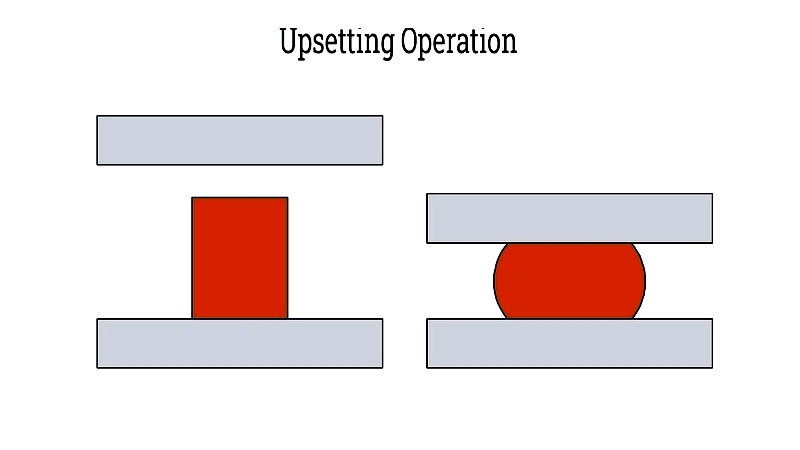

Upsetting Operation

Increases cross-section while reducing length, improving material integrity.

Cogging Operation

Refines grain structure through incremental deformation.

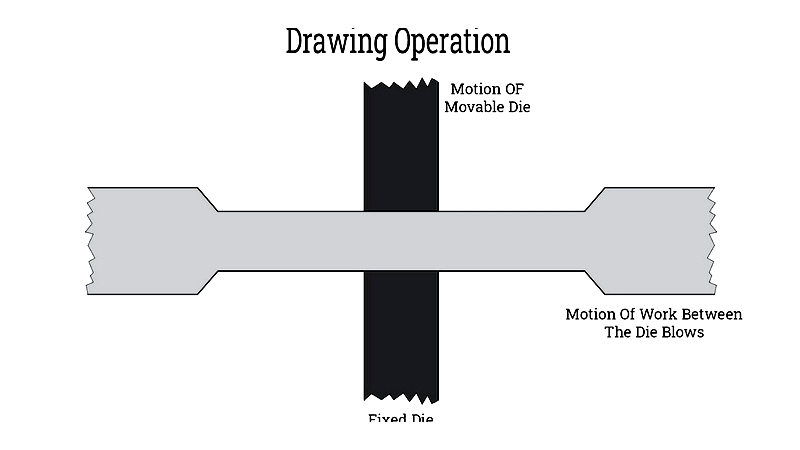

Drawing Process

Produces elongated components with aligned grain structure.

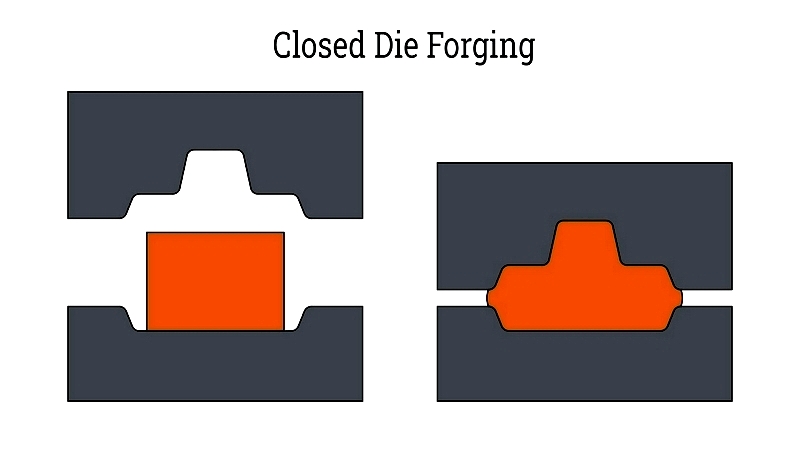

Closed Die Forging

This precision method uses detailed dies to create near-net-shape components with minimal machining.

Comparative Analysis

Chapter 3: Leading Forging Equipment

Modern forging relies on specialized machinery for consistent, high-quality production across industries.

Notable Machines

Industry-leading equipment includes Ajax-CECO's Bulldog 600, SMS Group's hydraulic presses, and Erie Press Systems' MultiForge™ series, each offering unique capabilities for different forging requirements.

For current specifications and purchasing guidance, consult manufacturers directly as technology evolves continuously.