Introduction

This article provides an in-depth examination of pressure gauges.

You will explore various topics including:

- The definition of a pressure gauge

- Pressure gauge operation principles

- Different pressure gauge types

- Practical applications of pressure gauges

- Additional relevant information

Chapter One: What is a Pressure Gauge?

A pressure gauge measures fluid, gas, water, or steam pressure in pressurized systems. These instruments are vital for detecting leaks or pressure variations that could impair system performance. Systems function best within specific pressure ranges, and deviations can significantly reduce efficiency.

Pressure gauges have evolved over a century to meet changing application demands. Their importance has grown alongside the expanding use of pressure systems across multiple industries.

Chapter Two: Pressure Gauge Types

Pressure gauges monitor and regulate pressure in industrial settings, ensuring safety, efficiency, and process control. Their design varies by application, with different sizes, styles, and materials for specific uses. Classification methods include:

- Application (industrial, process, HVAC, digital)

- Measured media (gases, liquids, steam)

- Measurement technique

Pressure measurement involves calculating perpendicular force per unit area. Accuracy depends on the reference point, affecting device selection. The two primary categories are hydrostatic and mechanical gauges, serving industries from oil & gas to pharmaceuticals.

- Hydrostatic Pressure: Created by stationary liquid weight above a measurement point. Liquid height determines pressure, influenced by density and gravity. Common in tank monitoring and groundwater applications.

- Mechanical Pressure: Measured through bellows, diaphragms, or Bourdon tubes that convert fluid pressure into force. Used in automation, hydraulics, and industrial maintenance.

Pressure measurement methods include absolute, gauge, differential, and atmospheric pressure. Understanding these is crucial for proper instrument selection.

- Absolute Pressure: Measured against perfect vacuum, essential for scientific and vacuum applications.

- Gauge Pressure: Relative to atmospheric pressure, positive or negative. Common in tires and industrial systems.

- Differential Pressure: Measures difference between two pressures, useful for filtration and flow monitoring.

Types of Pressure Gauges

Selection considerations include range, media, accuracy, conditions, and compliance. Common types include:

Absolute Pressure Gauge

Measures pressure independent of atmospheric changes using a vacuum reference. The diaphragm's deformation converts to pressure readings. Unaffected by altitude or weather, ideal for laboratories and aerospace.

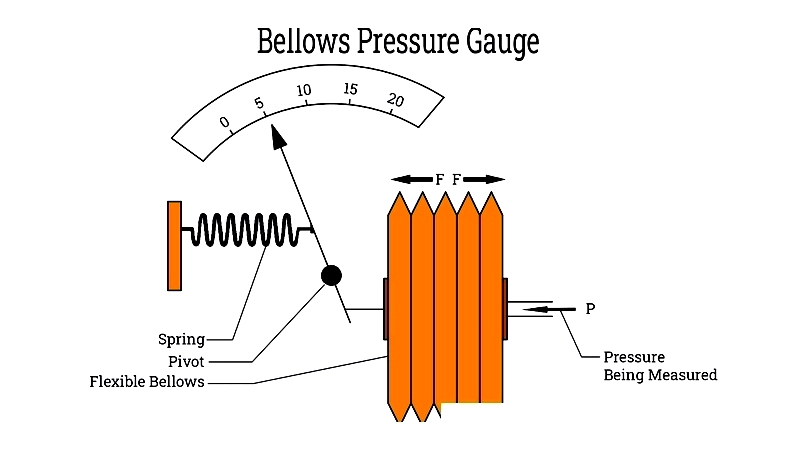

Bellows Pressure Gauge

Uses accordion-shaped metal tubes that expand under pressure. Suitable for low-pressure applications like medical equipment and gas systems.

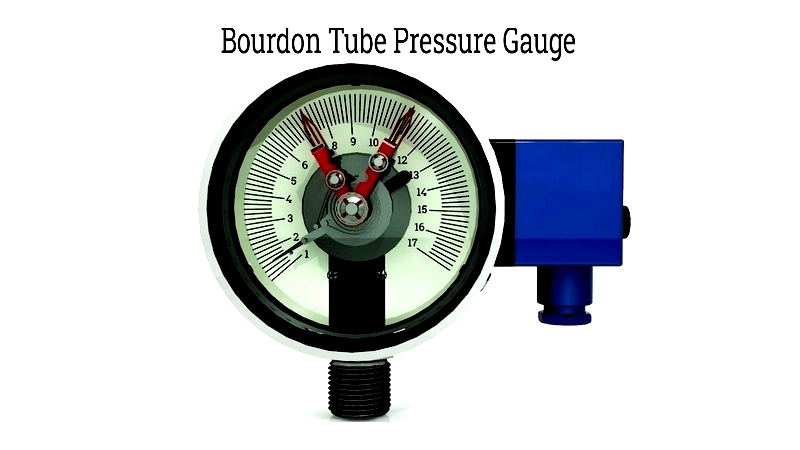

Bourdon Tube Pressure Gauge

Features a curved tube that straightens under pressure, moving a pointer. Measures from vacuum to 1000 bar, widely used in industrial processes.

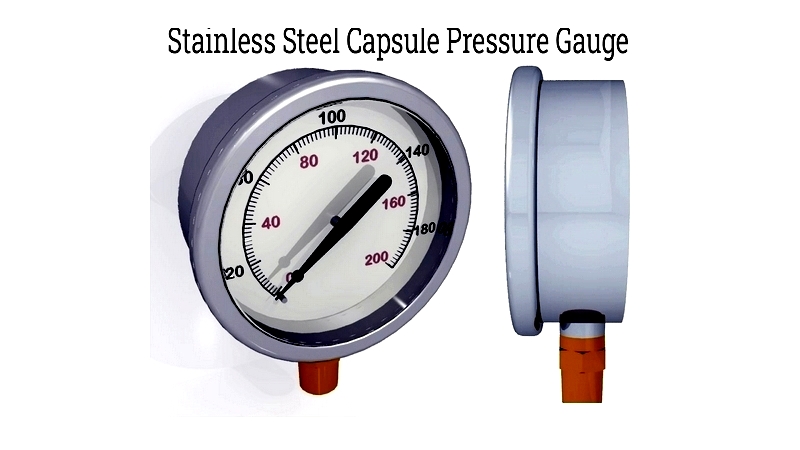

Capsule Pressure Gauge

Contains corrugated diaphragms for low gas pressure measurement (up to 600 mbar), used in ventilation and labs.

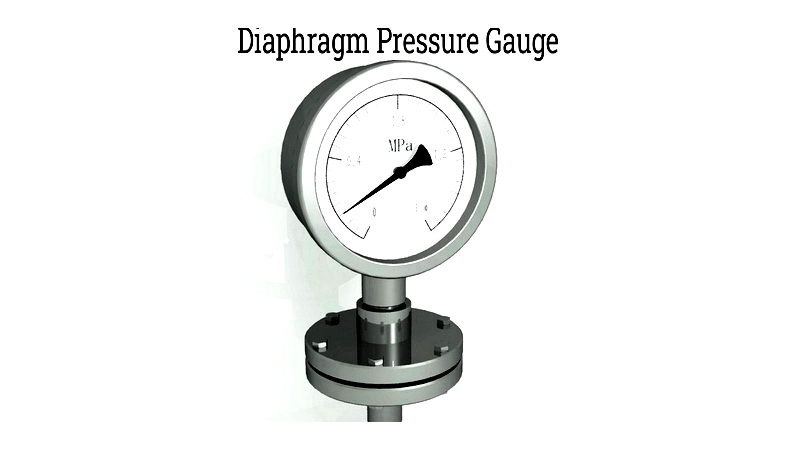

Diaphragm Pressure Gauge

Uses a flexible diaphragm instead of a tube, resistant to corrosive media. Common in chemical and wastewater applications.

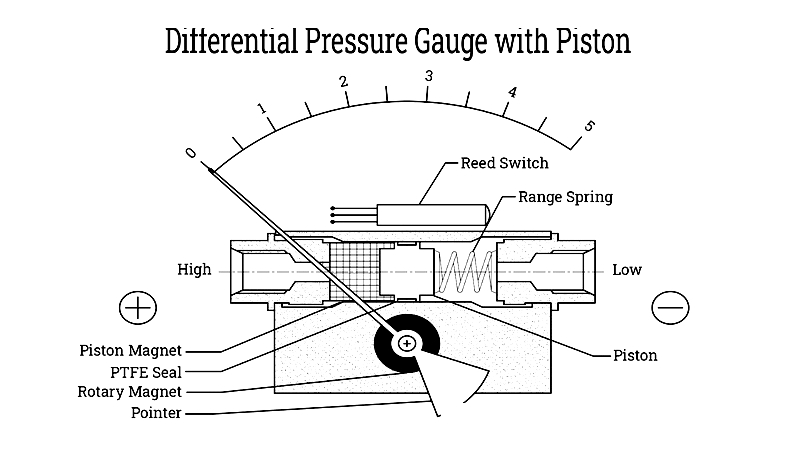

Differential (DP) Pressure Gauge

Measures pressure difference between two chambers, important for filtration and flow monitoring.

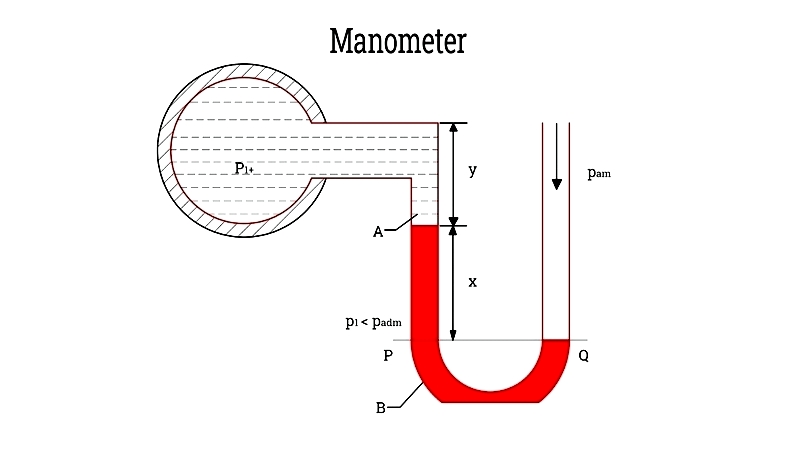

Manometer Pressure Gauge

Compares fluid columns in a U-tube, simple and reliable for calibration.

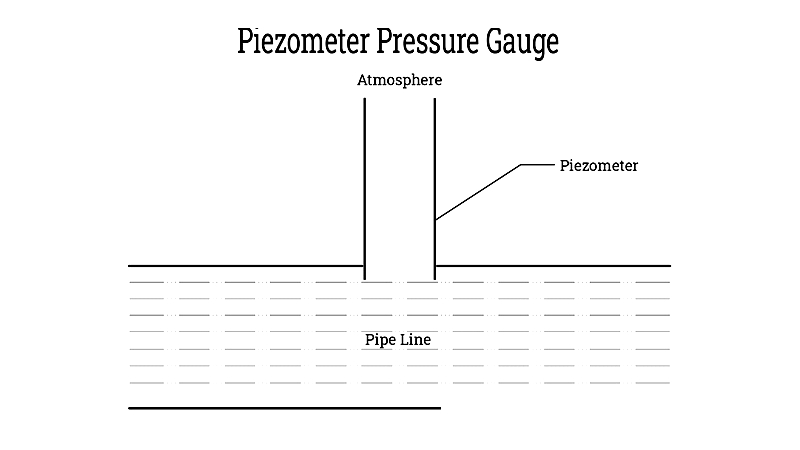

Piezometer Pressure Gauge

Measures liquid pressure through fluid height in a vertical tube, used in groundwater studies.

Specialty and Digital Pressure Gauges

Digital versions offer electronic sensing and data logging, suitable for modern industrial applications. Specialized gauges serve harsh environments like offshore platforms and food processing.