Introduction

This article provides an in-depth examination of hydraulic pumps.

It covers detailed information on various topics, including:

- Principle of Hydraulic Pumps

- Types of Hydraulic Pumps

- Applications and Benefits of Hydraulic Pumps

- And Much More…

Chapter 1: What is the principle behind hydraulic pumps?

This chapter explores the structure and functionality of hydraulic pumps.

Understanding Hydraulic Pumps

Hydraulic pumps are essential components in hydraulic systems, converting mechanical energy into hydraulic energy by moving fluid. They are sometimes mistakenly called "hydrolic" pumps.

In hydraulics—a branch of power transmission—hydraulic pumps control pressurized fluids to convert energy into mechanical power. These pumps are widely used in commercial, industrial, and consumer applications.

Power transmission involves converting energy into usable forms. It includes three main categories: mechanical, electrical, and fluid power. Fluid power uses gases and liquids to transmit energy, with hydraulics focusing on liquids and pneumatics on compressed gases.

Constructing a Hydraulic Pump

According to Pascal's Law, hydraulic systems require confined liquids. A hydraulic power unit consists of basic components like a reservoir, valves, piping, pump, and actuators. These components work together to form the foundation of all hydraulic systems.

Hydraulic Pump Reservoir

The reservoir stores fluid, dissipates heat, removes impurities, and releases air and moisture from the fluid.

Hydraulic Pump

The pump converts mechanical energy into hydraulic energy by moving fluid against resistance or pressure.

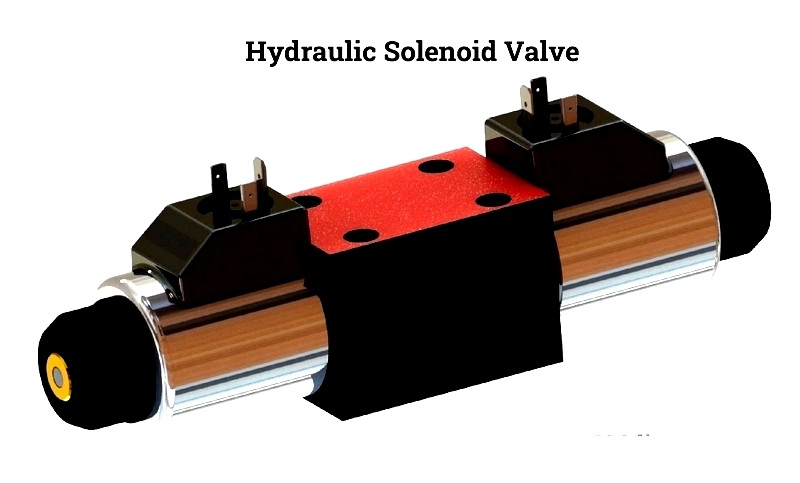

Hydraulic Pump Valves

Valves control fluid flow, starting, stopping, and directing it through the system. They can be operated hydraulically, pneumatically, manually, electronically, or mechanically.

Hydraulic Pump Actuators

Actuators convert hydraulic energy back into mechanical energy, producing linear or rotational motion.

The Mechanics of Hydraulic Power

Hydraulics relies on the incompressibility of fluids to transmit force efficiently. Pascal's Principle states that pressure applied to a fluid is evenly distributed throughout it.

Force can be amplified in hydraulic systems by adjusting piston areas. For example, a small force on a small piston can produce a larger force on a larger piston.

Hydraulic systems allow significant force application with minimal effort, using fluids like oil or water.

Operational Dynamics of Hydraulic Pumps

- The reservoir stores hydraulic fluid.

- The pump circulates fluid through the system.

- Tubes or hoses transport the fluid to actuators.

- Actuators convert hydraulic energy into mechanical energy.

- Valves regulate pressure and flow direction.

Factors in Selecting Hydraulic Pumps

Hydraulic systems should integrate with other power transmission methods for optimal performance. Choosing the right pump depends on its intended application.

Material Composition of Pumps

Pump materials must withstand operational stresses and fluid compatibility. Common materials include aluminum, stainless steel, and steel.

Pump Performance Attributes

Key specifications include operating pressure, horsepower, speed, and flow rate.

Addressing Inefficiencies in Hydraulic Systems

System inefficiencies, like air bubbles, should be minimized for optimal performance.

Chapter 2: What are the Different Types of Hydraulic Pumps?

Hydraulic pumps convert mechanical energy into hydraulic energy for various applications. The main types are gear pumps and piston pumps, each suited for specific tasks.

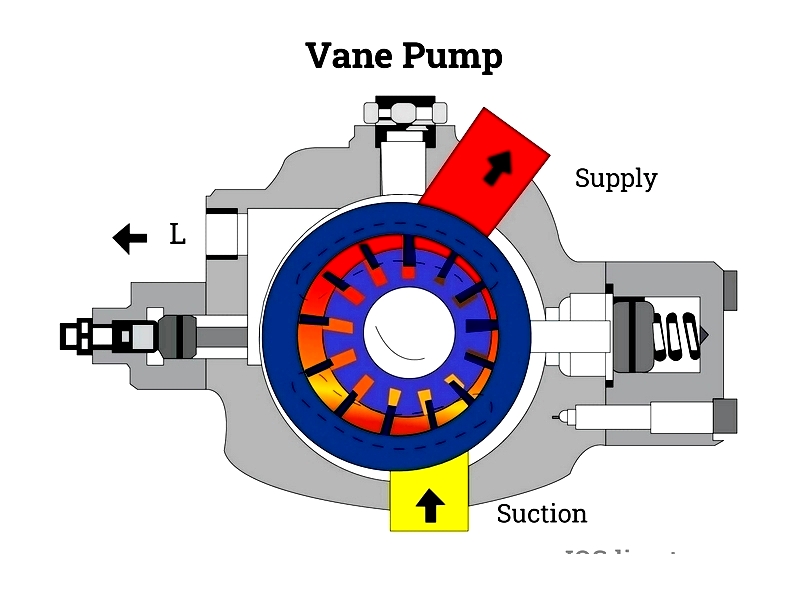

Vane Pump

Vane pumps provide consistent flow and are known for quiet operation.

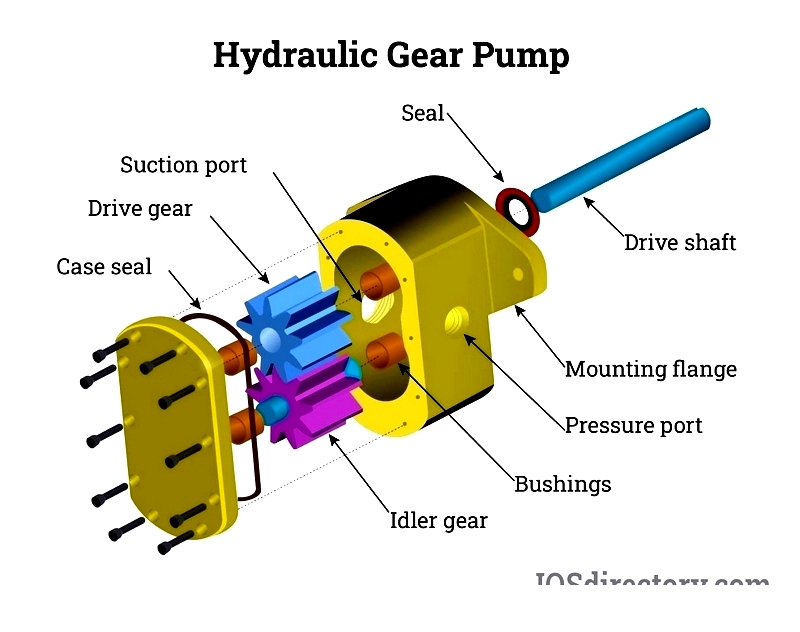

Hydraulic Gear Pump

Gear pumps include external and internal types, offering durability and steady flow.

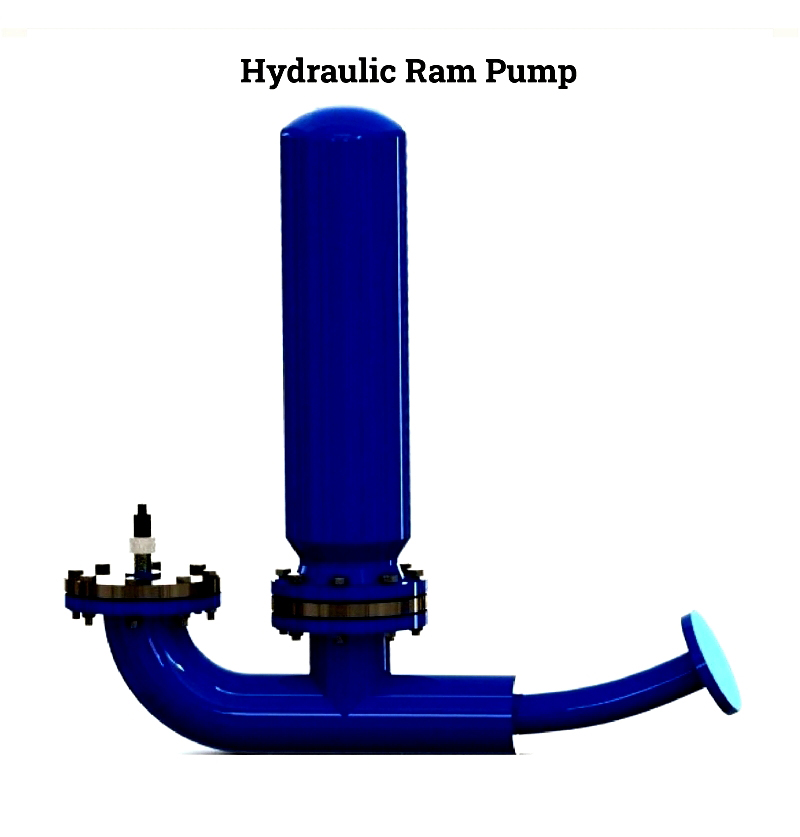

Hydraulic Ram Pump

Ram pumps use water momentum to lift water without external power.

Hydraulic Water Pump

Water pumps transfer water for various applications, including irrigation and firefighting.

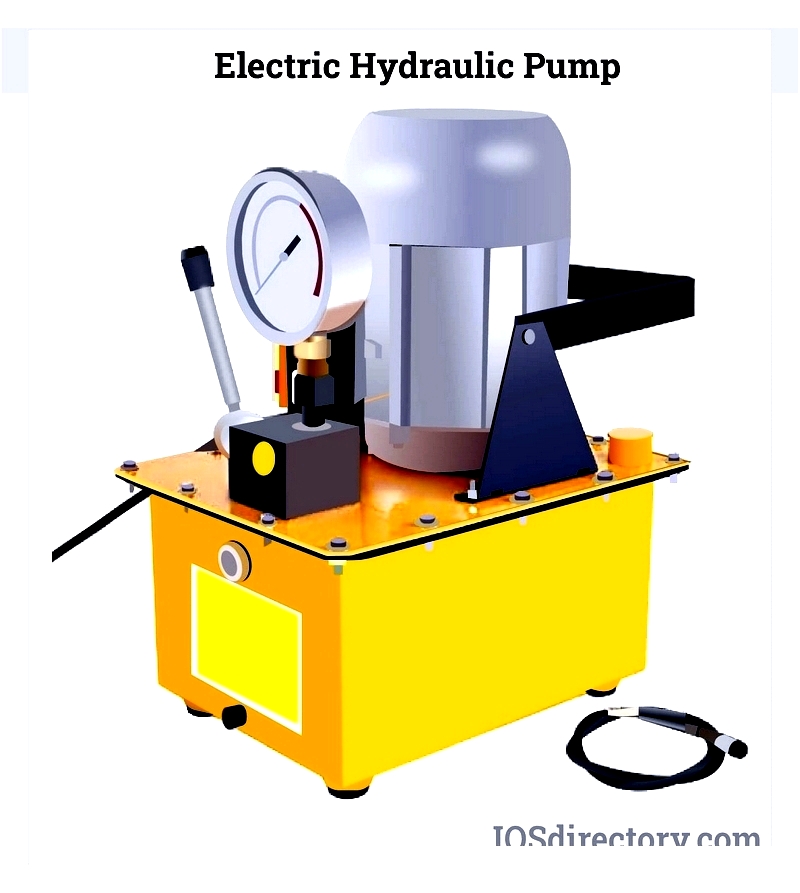

Electric Hydraulic Pump

Electric pumps use electricity to drive hydraulic fluid transfer.

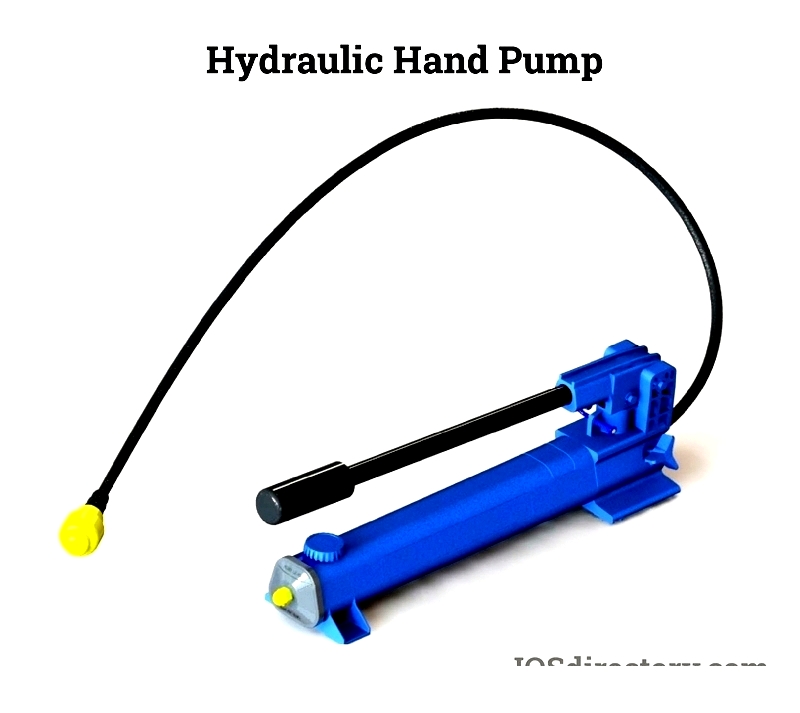

Hydraulic Hand Pump

Hand pumps are manual devices for fluid transfer in various applications.

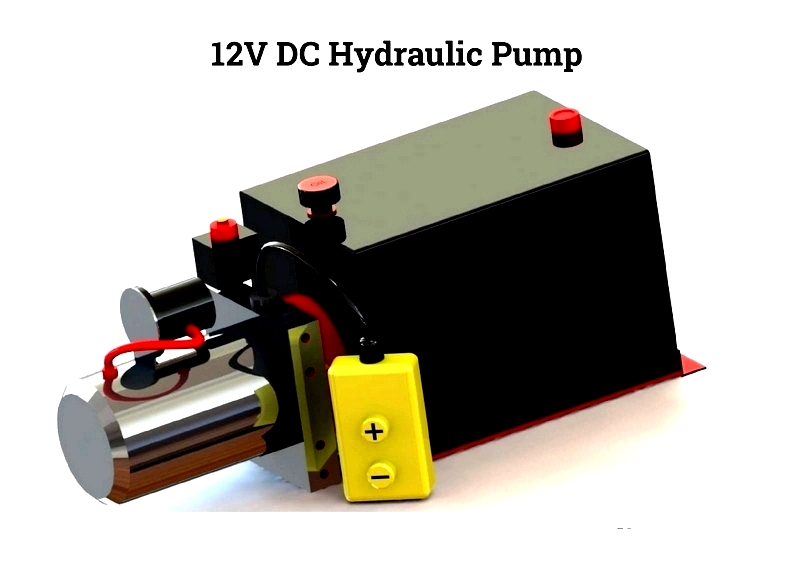

12V Hydraulic Pump

12V pumps are compact and portable, ideal for mobile applications.

Air Hydraulic Pump

Air pumps use compressed air to drive hydraulic systems.

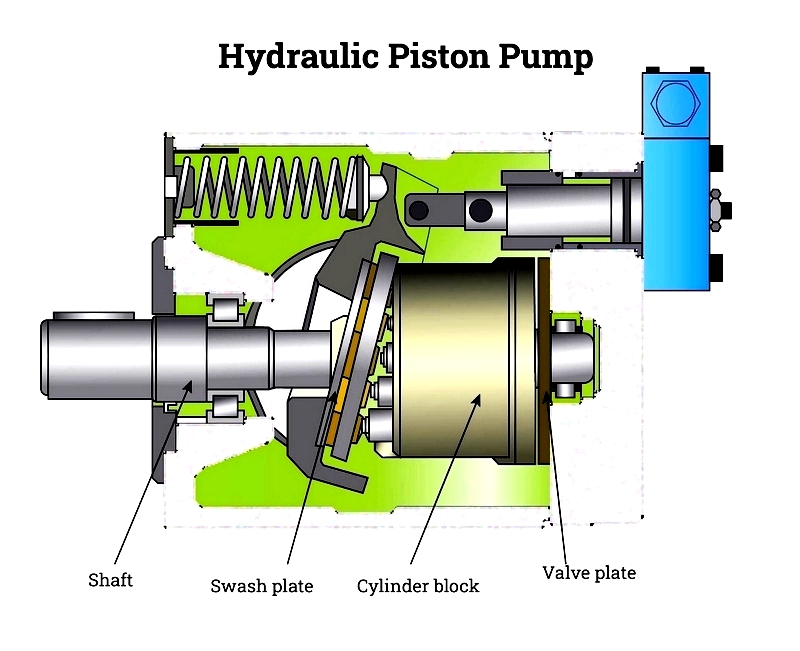

Hydraulic Piston Pump

Piston pumps generate high pressure for heavy-duty applications.

Hydraulic Clutch Pump

Clutch pumps enable precise torque transfer in transmissions.

Hydraulic Pumps

Hydraulic pumps are versatile and efficient, forming the core of hydraulic systems.