Introduction

This article provides information about altitude chambers and their applications.

You will explore topics including:

- What an Altitude Chamber is

- Applications of Altitude Chambers

- Construction of Altitude Chambers

- Regulations and Standards for Altitude Chambers

- And More...

Chapter One – What is an Altitude Chamber?

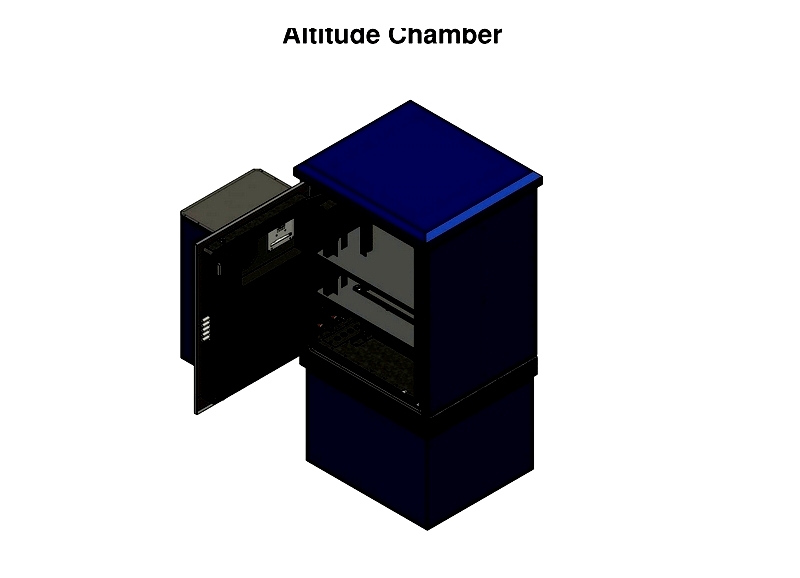

An altitude chamber is a specialized testing environment designed to simulate high-altitude conditions, including altitude, vacuum, and temperature variations that mimic aircraft flight conditions. These chambers test the performance and durability of aircraft components, particularly those exposed to airborne transportation, ensuring their reliability under extreme circumstances.

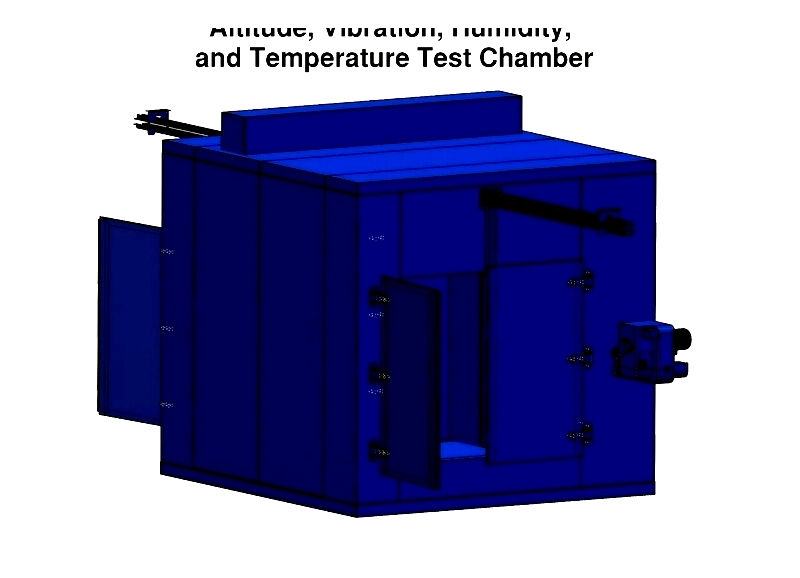

Unlike hypobaric test chambers that only simulate low-pressure conditions, altitude test chambers incorporate multiple factors such as temperature, humidity, icing, and sometimes vibrations. This comprehensive approach enables accurate replication of real-world high-altitude environments.

Chapter Two – Applications of Altitude Test Chambers

Altitude test chambers are often confused with hypobaric test chambers due to their shared focus on altitude effects. However, their purposes differ significantly. Those unfamiliar with the industry sometimes mistakenly associate chambers used for athletic training or terrestrial altitude studies with industrial altitude test chambers. While these terms are frequently used interchangeably, they serve distinct purposes.

Industrial altitude test chambers simulate much more extreme conditions than those used for human performance evaluation. This difference stems from the need to test the strength, durability, and resilience of aircraft components and equipment transported under demanding conditions. These chambers create rigorous environments to ensure critical equipment reliability.

Altitude Test Chamber Applications

High and Low Altitude Simulation

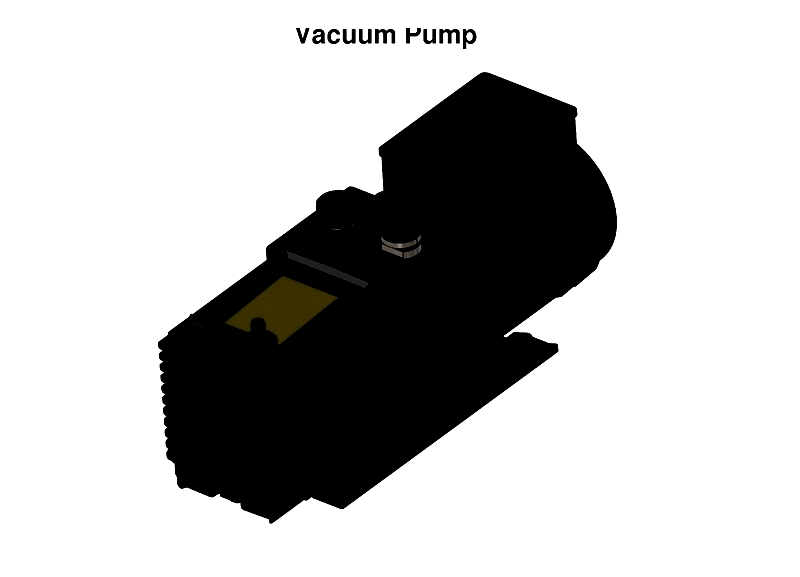

Specialized equipment is required to accurately replicate high-altitude conditions at thousands of feet. Various vacuum pump sizes create atmospheric conditions equivalent to altitudes up to 100,000 feet, with some systems reaching 200,000 feet.

High altitudes present challenges like significant cabin pressure loss. Altitude chambers can simulate this through rapid decompression in 15 seconds or less.

While primarily designed for high-altitude simulation, these chambers can also reproduce pressure variations below sea level.

Programmable controls and instrumentation can model factors like high altitude, rapid decompression, and sub-sea level pressure. These advanced systems quickly establish test conditions that meet specific parameters, enhancing safety, improving product quality, and providing vital data for personnel and equipment protection.

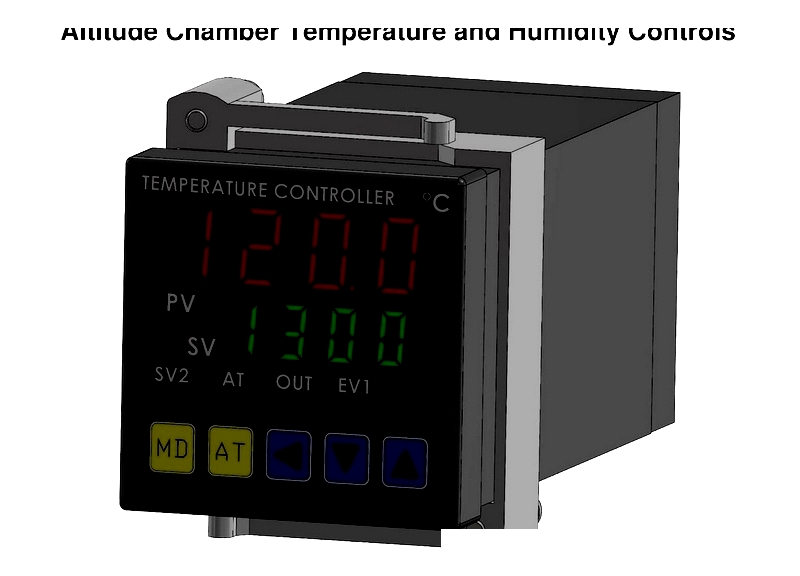

Temperature Control

Altitude test chambers replicate various extreme high-elevation conditions, with temperature matching achieved through single-stage or cascade refrigeration systems.

Precise temperature control is essential, requiring chambers to both heat and cool while maintaining uniform temperatures throughout. This precision characterizes high-quality altitude test chambers.

Single Stage Refrigeration System

In single-stage systems, refrigerant undergoes compression in one cycle with separate pressure settings for evaporator and condenser. This cost-effective system effectively manages specific temperature ranges.

Cascade System

Cascade refrigeration systems use one refrigerant to condense another at the desired evaporator temperature. The high-stage circuit cools a low-stage circuit, achieving temperatures as low as -120°C. Known for energy efficiency, low operating costs, and easy maintenance, these systems are ideal for precise temperature regulation in altitude test chambers.

Offering wide temperature ranges and excellent precision, cascade systems are preferred for generating accurate altitude conditions.

Humidity Testing

Beyond temperature and altitude simulation, altitude test chambers conduct humidity testing to better replicate real-world high-altitude environments.

Humidity significantly impacts material durability, affecting coatings, paints, and metals. Humidity testing evaluates material resilience, contributing to improved product longevity and reliability.

Vibration Testing

Vibration testing evaluates product resilience against aviation-related vibrations, simulating conditions during transportation, flight operations, and control system use. This test identifies component failure points by applying vibrational stresses.

The results reveal product limitations and provide data for design and functionality improvements.