Introduction

This is the most comprehensive online guide available

You'll discover:

- How Pressure Tanks Work

- Different Categories and Varieties of Pressure Tanks

- Practical Uses and Advantages of Pressure Tanks

- Plus additional valuable information...

Chapter 1: Understanding Pressure Tank Principles

This section explores the fundamentals of pressure tanks, their manufacturing process, and their diverse applications.

Pressure Tank Basics

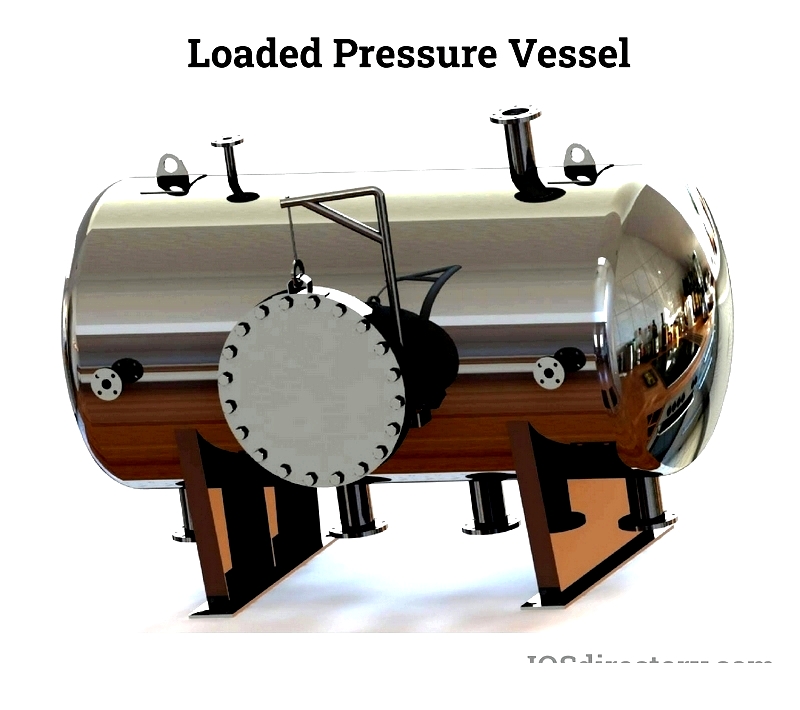

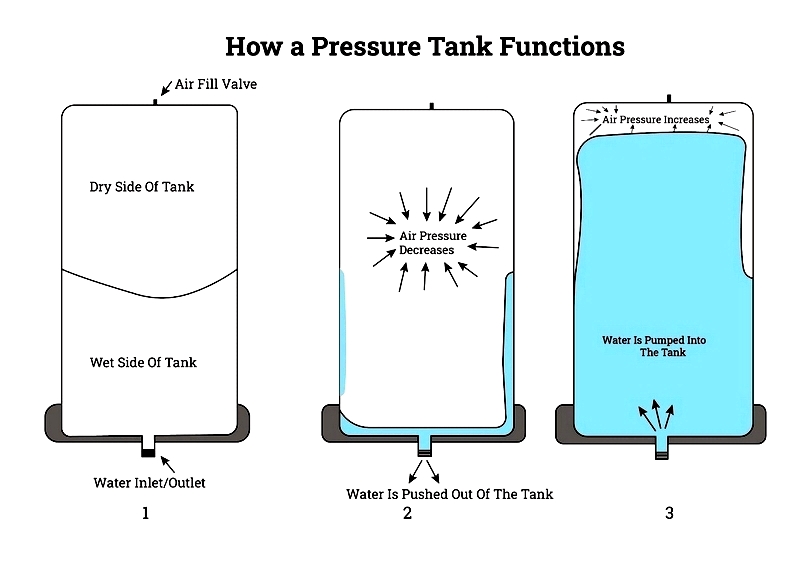

Pressure tanks are specialized containers designed to store, regulate, and transport gases, vapors, or liquids at pressures exceeding normal atmospheric conditions.

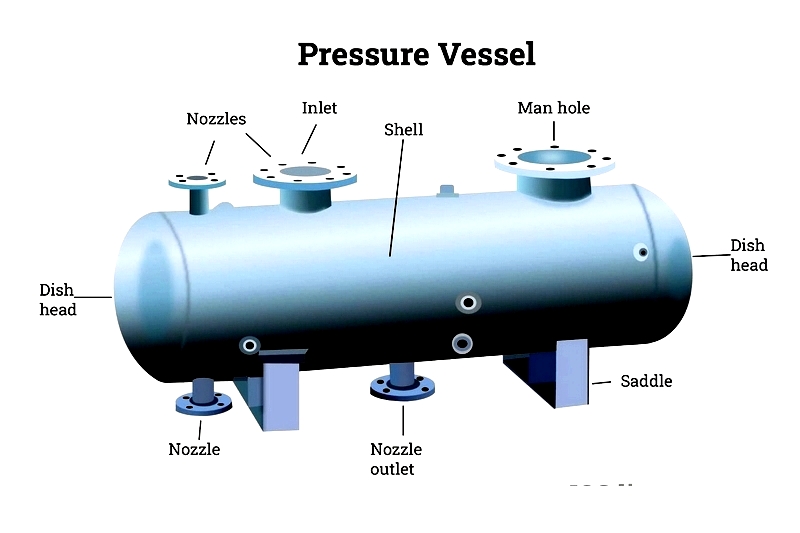

Understanding Pressure Vessels

Pressure vessels are sealed containers that store liquids, vapors, and gases at pressures significantly different from ambient conditions. Widely used across industries including petrochemical, oil and gas, chemical processing, and food production, they include various equipment like reactors, separators, and heat exchangers.

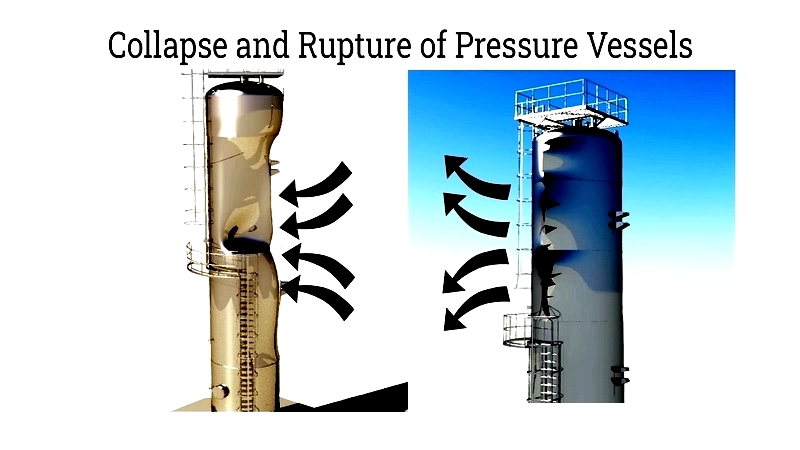

These vessels operate within strict temperature and pressure limits to maintain safety. Certified professionals design, manufacture, and inspect them according to rigorous standards like API 510 and ASME Section 8 to prevent hazardous incidents.

Comparing Pressure Tanks and Vessels

The key difference lies in their pressure handling capacity. Pressure vessels manage much higher pressures (often above 15 PSI, sometimes reaching 3000 PSI), while pressure tanks typically store liquids at lower pressures (15 PSI or below).

Pressure vessels follow ASME Section VIII standards, while pressure tanks adhere to industry-specific guidelines like API 650, API 620, and AWWA D100. Generally, pressure vessels are fully enclosed, whereas tanks may be open or sealed, with tanks usually having greater capacity but vessels requiring more careful maintenance.

Pressure Tank Production

Manufacturing involves several critical steps:

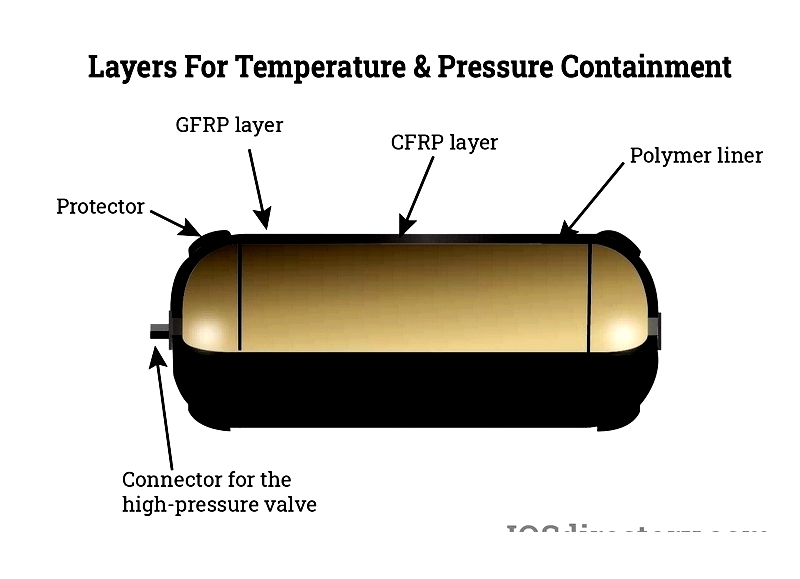

Material Selection

Steel and stainless steel are common choices for their strength and durability. Stainless steel offers additional benefits like corrosion resistance, making it ideal for food, medical, and laboratory applications.

Other materials include aluminum, carbon fiber, and high-strength polymers. Selection considers factors like strength requirements, corrosion resistance, cost-effectiveness, manufacturability, and material availability.

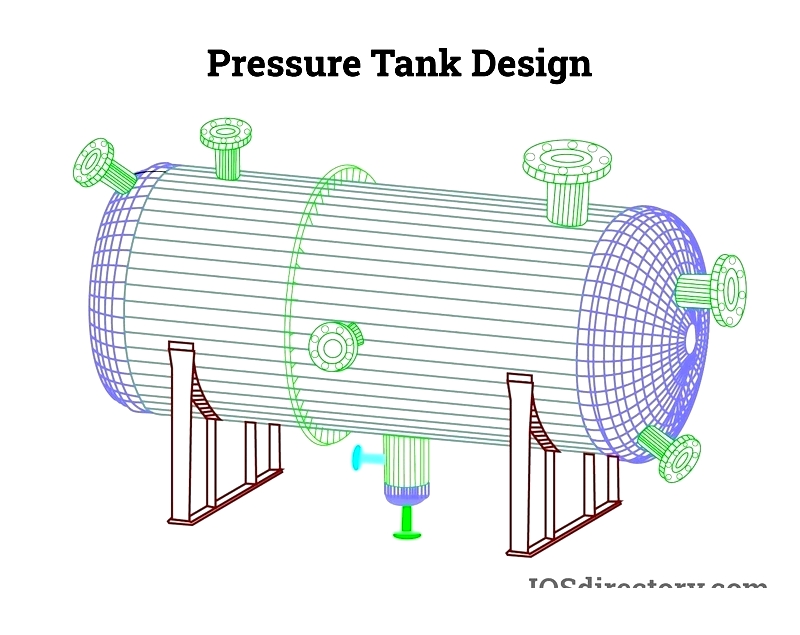

Design Considerations

Key design parameters include:

Design Pressure: Set 5-10% above maximum operating pressure to account for process variations.

MAWP: The maximum safe operating pressure determined by material limits.

Design Temperature: Accounts for operational temperature ranges and potential fluctuations.

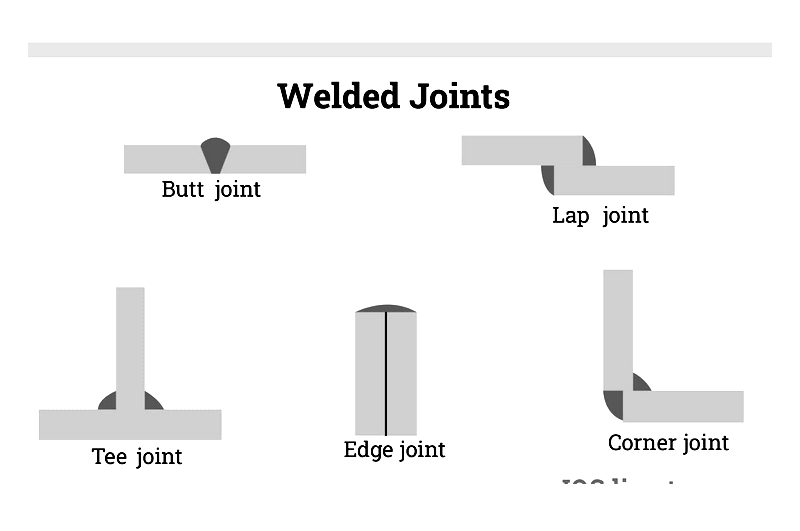

Additional factors include maximum stress tolerance, joint efficiency in welded connections, and appropriate corrosion allowances based on the operating environment.

Fabrication Process

Manufacturing involves shaping metal plates through forging and welding, then adding components like nozzles, relief valves, and support structures. Post-weld heat treatment reduces residual stresses.

Pressure Tank Specifications

ASME-certified tanks meet rigorous standards for design and safety. Other relevant standards include UL, ASTM, TUV, and ISO. Regular inspections maintain certification, though non-code vessels are also available.

Pressure Tank Operation

These vessels maintain specific pressure levels through valves and gauges, handling pressures from 15 psi to extreme levels in specialized applications.

Selection Criteria

Key factors when choosing pressure tanks:

Material Choice

Options range from carbon steels to specialized alloys, selected based on operating conditions and budget.

Design Quality

Proper design ensures durability, with welding quality being particularly crucial.

Compliance Standards

important certifications include ASME Section 8, TUV, and ISO 9001:2015.

Testing Procedures

Manufacturers conduct various tests including hydro-testing, radiographic examination, and non-destructive evaluations to ensure quality and safety.