Introduction

This guide covers all essential information about graphite crucibles available online.

You'll discover:

- The definition of graphite crucibles

- Common applications of graphite crucibles

- Manufacturing process of graphite crucibles

- Maintenance tips for graphite crucibles

- Additional valuable insights

Chapter One – Understanding Graphite Crucibles

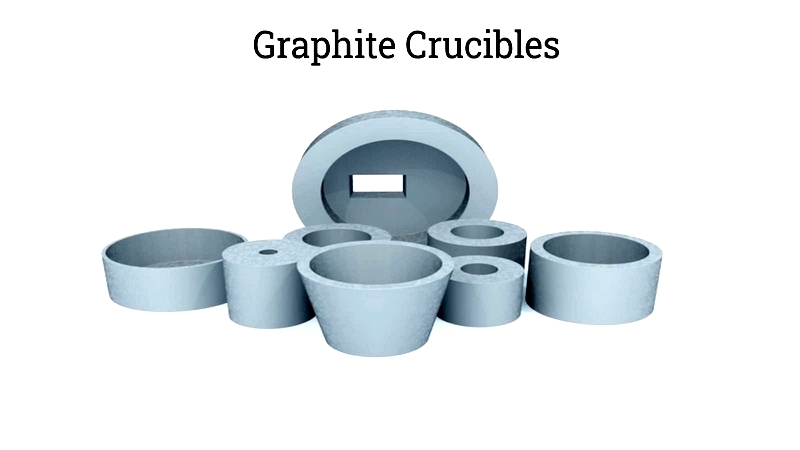

Graphite crucibles serve as essential containers for melting and pouring various metals like gold, silver, aluminum, and brass. Their popularity stems from excellent thermal conductivity, high-temperature resistance, and minimal thermal expansion under extreme conditions. These crucibles can withstand rapid temperature fluctuations, making them ideal for metal casting. Additionally, they demonstrate remarkable resistance to chemical corrosion from both acidic and alkaline solutions, ensuring long-term durability.

Manufactured from natural crystalline carbon, graphite is combined with heat-resistant materials like clay or carbon dioxide to enhance its high-temperature performance.

Synthetic graphite is produced from petroleum byproducts such as pitch and coke during oil refining. This type features high carbon content, minimal impurities, and low sulfur levels, delivering superior performance across various applications.

Graphite crucibles preserve metal purity as their integrated material remains stable without contamination. Quality depends on manufacturing processes that determine structure, density, porosity, and strength.

Chapter Two – Applications of Graphite Crucibles

Graphite crucibles excel in metal casting due to their inert properties and exceptional thermal characteristics. These specialized containers play a vital role in melting and refining both ferrous and non-ferrous metals, including aluminum, copper, gold, silver, platinum, steel, and brass across various industries. Their superior heat conductivity enables rapid, uniform metal melting, enhancing efficiency and reducing production cycles. Chemical and corrosion resistance maintains material purity while minimizing waste, offering durability that benefits both small jewelers and large foundries.

Precise temperature control during metal casting is crucial for modifying alloy properties. Graphite crucibles maintain structural integrity beyond 1600°C (2912°F), accommodating diverse metals in various environments.

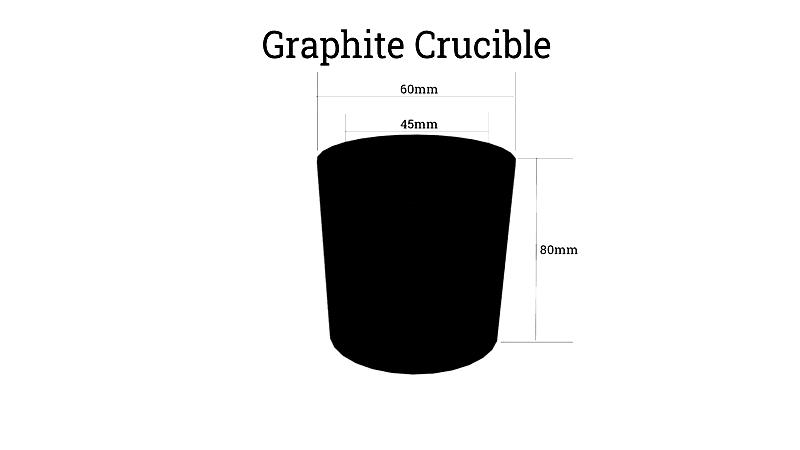

Available in multiple shapes and sizes, graphite crucibles follow a classification system starting with "A," with specifications based on dimensions and capacity. Designs vary from simple cylinders to complex configurations with spouts or lids for specific applications.

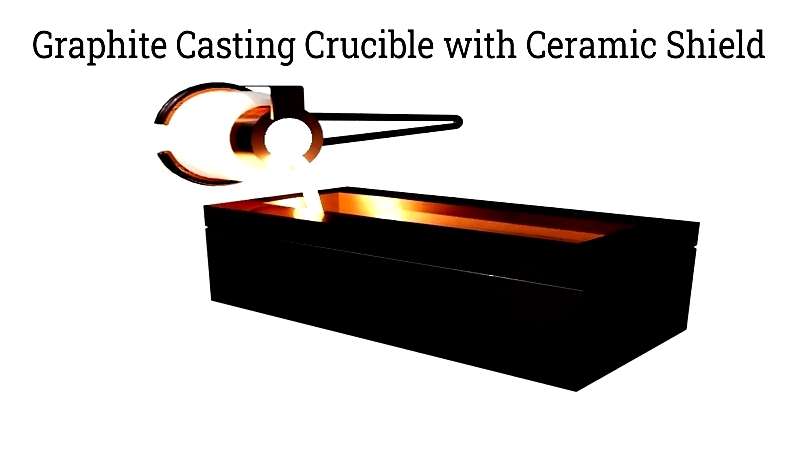

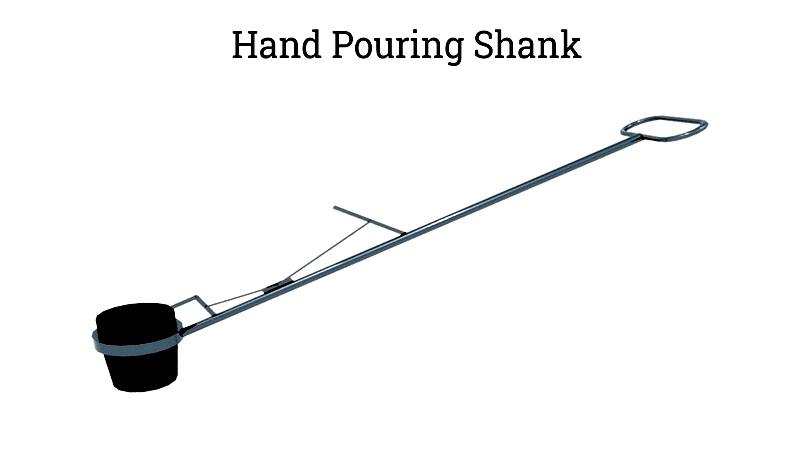

Custom features like lifting grooves or handles improve safety and functionality. These crucibles serve applications ranging from jewelry making to industrial-scale production, integrating seamlessly with furnace systems.

Their versatility extends to different furnace types, including fuel-fired, electric resistance, and induction models, adapting to various melting environments and purity requirements.

Fuel Fired Furnace

Fuel-fired furnaces utilize gas, oil, propane, or coke, requiring crucibles that can withstand maximum energy output. Their tapered design ensures even heat distribution, making them suitable for alloy steel, bronze, brass, and cast iron melting while preventing oxidation and slag buildup.

Electric Resistance Furnace

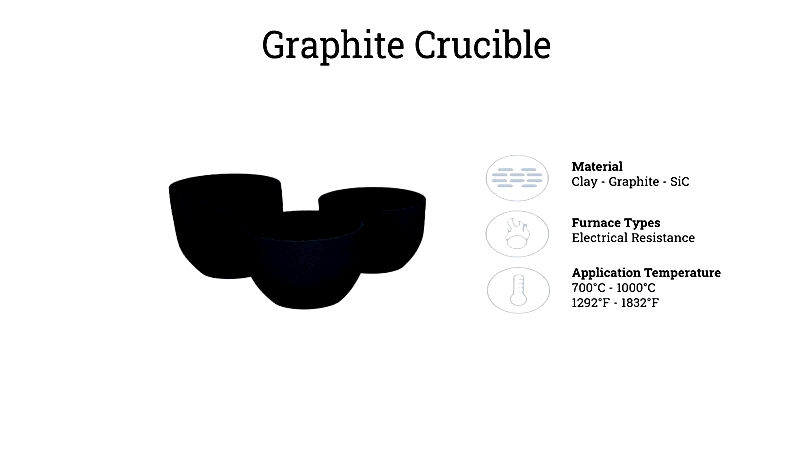

These furnaces need specially designed crucibles with high synthetic graphite content for improved efficiency. Basin-shaped crucibles surround heating elements for uniform temperature distribution, ideal for aluminum, copper, and precious metal applications requiring minimal contamination.

Induction Furnace

Induction furnaces present unique challenges, with crucibles serving dual roles in melting and electromagnetic field management. Material selection depends on operating frequency, with silicon carbide enhancing conductivity in low-frequency systems and clay graphite resisting magnetic forces in high-frequency applications.

Removable Crucible Furnaces

Designed for easy handling, these "A"-shaped crucibles facilitate batch processing and alloy changes. Their ergonomic design enhances safety and workflow efficiency in various metalworking operations.

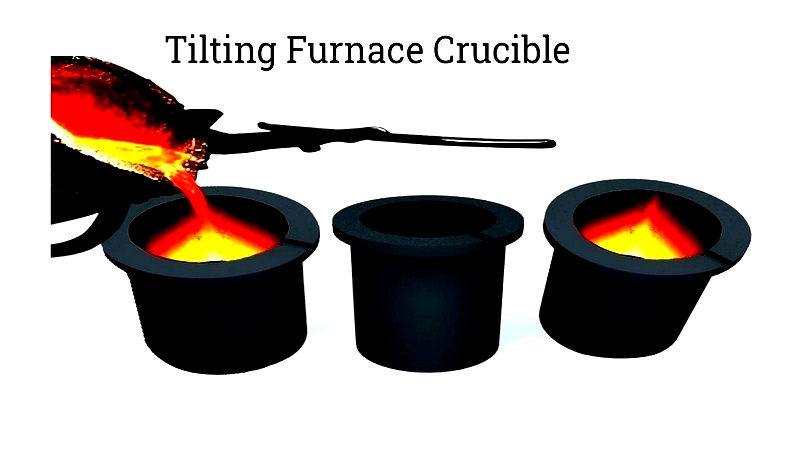

Tilting Furnace

In these systems, stationary crucibles allow furnace housing to tilt for pouring, reducing manual handling. Suitable for diverse metals, they're ideal for high-volume production requiring precise temperature control.

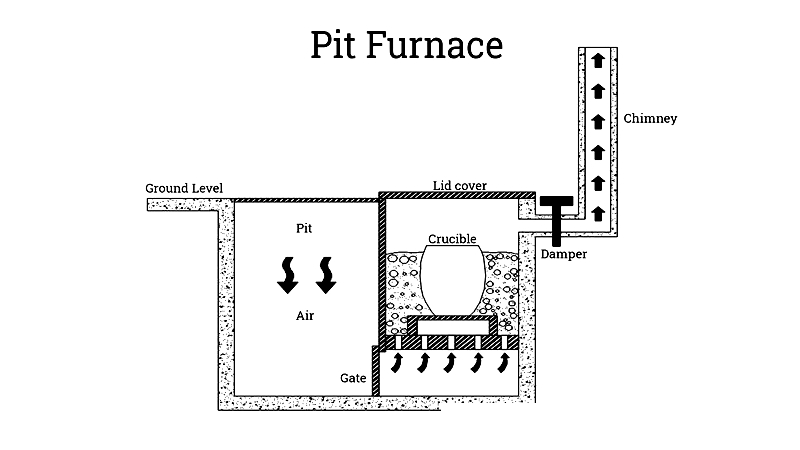

Pit Furnace

Subterranean pit furnaces provide natural insulation, using coke as both fuel and insulator. This traditional method offers stable heating for large quantities of precious and base metals, maintaining quality through controlled environments.