Introduction

This article covers everything you should know about vacuum chambers.

You will learn about:

- The definition of a vacuum chamber

- Different types of vacuum chambers

- Industries utilizing vacuum chambers

- Tests and operations conducted in vacuum chambers

- And more...

Chapter One – Understanding Vacuum Chambers

A vacuum chamber creates a sealed environment where air and pressure are removed to study how materials, components, and assemblies behave under vacuum conditions. These chambers are crucial for assessing manufacturing process efficiency. Built to withstand pressure differentials, they can simulate various environmental scenarios.

In aerospace and space industries, vacuum testing verifies component durability against extreme space conditions. This testing is equally important for ensuring packaging security during air transport.

Industrially, vacuum chambers facilitate high-altitude simulations, drying processes, and offgassing operations. These procedures are essential for validating product integrity and durability.

Chapter Two – Types of Vacuum Chambers

Vacuum chambers are designed to meet industry demands, offering precise environmental control for various testing and manufacturing needs. They range from compact benchtop models for small-scale testing to room-sized enclosures for large aerospace components.

As specialized environmental test chambers, they simulate controlled conditions for vacuum testing, altitude testing, and thermal cycling. While standard models are available, industries often require custom solutions for specific applications.

Types of Vacuum Chambers

Available in multiple configurations, vacuum chambers are categorized by geometry: box, sphere, cylinder, D-shaped, and bell jar designs. Each type offers unique advantages for different pressure ranges and applications.

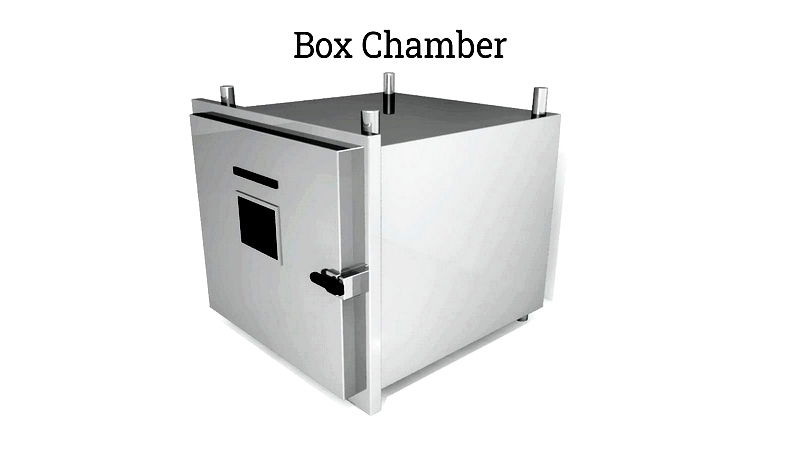

Box Vacuum Chambers

Box-shaped chambers come in rectangular and cubic forms, suitable for various industrial and laboratory uses. Rectangular chambers excel in ultra-high vacuum applications, supporting processes like thin film deposition and space simulation.

Built with thick walls and precision welding, these chambers maintain structural integrity under pressure. Materials like stainless steel or aluminum ensure durability and minimize outgassing.

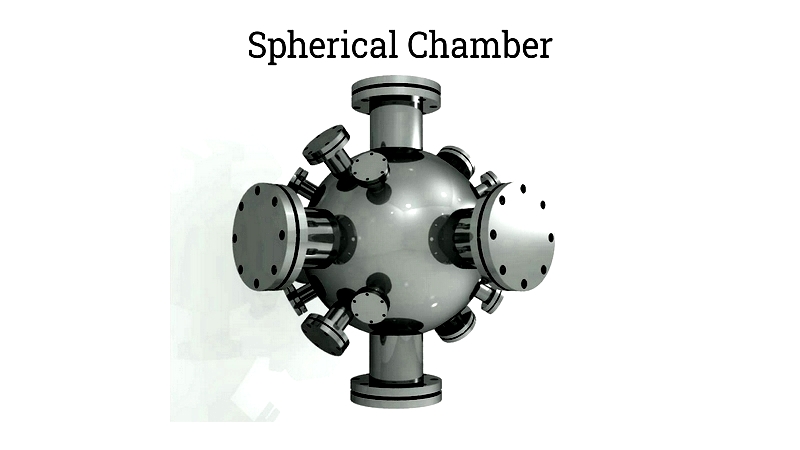

Spherical Vacuum Chambers

Spherical chambers provide uniform pressure distribution and multi-angle access, ideal for surface science and plasma research. Their design allows for multiple instrument connections.

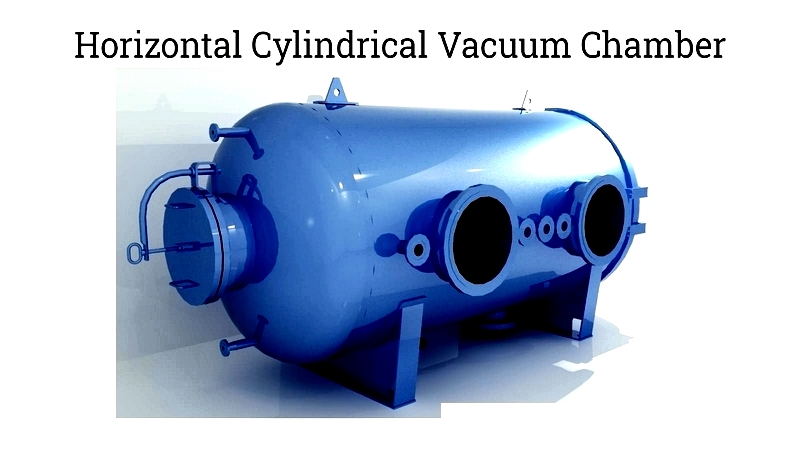

Cylindrical Vacuum Chambers

Cylindrical chambers, available in vertical and horizontal orientations, are cost-effective and widely used. Horizontal models offer easy access, while vertical versions enable rapid evacuation for space simulation and drying applications.

Bell Jar Vacuum Chambers

Bell jar chambers feature domed tops and are common in labs for basic vacuum processes. Available in metal or glass, they allow visual monitoring and support various testing applications.

Glass versions offer chemical resistance and visibility, while metal jars provide higher durability and vacuum compatibility.

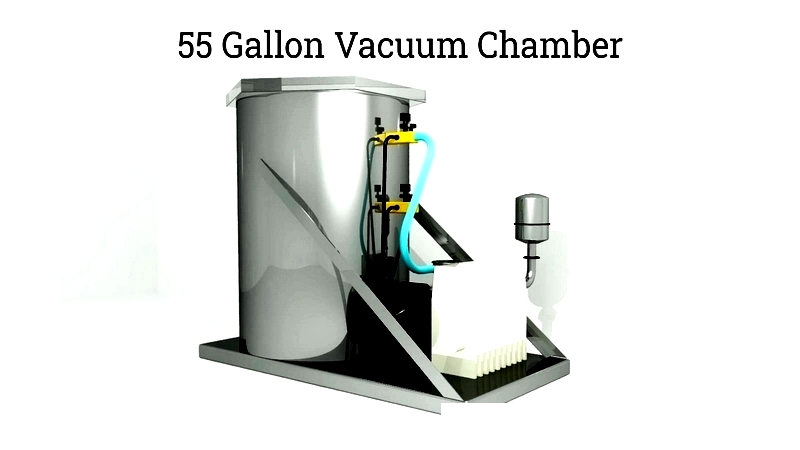

55 Gallon Drum Vacuum Chambers

These economical chambers handle bulk degassing and material processing. Ideal for resin casting and composite manufacturing, they offer large capacity with robust construction.

Comparing Vacuum Chamber Types

Selection depends on factors like vacuum pressure requirements, size, material compatibility, and testing protocols. Choosing the right geometry affects performance, maintenance, and system integration.