Introduction

This article provides an in-depth exploration of leak detectors.

You will learn about key topics including:

- What is a leak detector?

- Different types of leak detectors

- Applications of leak detectors

- Materials that require leak detection

- And more...

Chapter One – What is a Leak Detector?

A leak detector is an essential sensor used to monitor systems containing liquids, gases, or other materials to ensure they remain contained and don't escape. The detection process employs various sensors, tools, and equipment specifically designed to identify faults in closed systems.

Selecting a leak detector depends primarily on the leak characteristics, determined by the escape rate of gases or liquids. Key factors include the pressure difference between the system's interior and exterior, leak size, and substance density. Leak rate calculators can determine leakage rates through different hole shapes using specific gravity values for fluids like water, seawater, diesel fuel, SAE 30 oil, and gasoline. This data helps estimate leak diameters accurately. Engineers often use complex mathematical formulas to assess leakage rates.

Leak detection can be performed manually with handheld inspectors providing immediate readings or through automated systems offering continuous monitoring. The primary goal is to prevent, control, and minimize unintended releases of gases or liquids.

Chapter Two – What are the advantages and disadvantages of using lead screws?

Leaks pose significant risks in fluid transport and process systems, occurring at junctions like pumps, valves, pipe fittings, and compressors. Effective leak detection is crucial for predictive maintenance, safety compliance, and asset management across residential plumbing, water supply networks, and industrial pipelines. Reducing leaks protects assets, ensures environmental safety, and maintains regulatory compliance, especially in chemical processing, HVAC, pharmaceuticals, and oil & gas sectors.

Accurately determining leak size, rate, and location remains challenging for maintenance teams. Selecting the right detection system requires identifying acceptable leak sizes—often defined by industry standards—and critical failure thresholds. These factors guide the choice of detection technology, whether for gaseous or liquid leaks.

In industrial settings, leak detection monitors product flow in manufacturing lines, refineries, and utility plants. Commercial applications like HVAC and food processing rely on advanced detectors to prevent product loss and maintain performance. Detection methods include chemical analysis, pressure decay, thermal conductivity, ultrasonic monitoring, and mass spectrometry. System selection depends on the environment, medium, and required sensitivity.

Modern methods like tracer gas technology track specific substances such as helium, hydrogen, or UV-reactive dyes. These systems detect minute concentrations based on the tracer's unique properties, triggering visual, audible, or digital alerts for proactive maintenance.

Leak Detection Devices

Acoustic Leak Detector

Acoustic detectors identify leaks by recognizing sound frequencies from escaping fluids or gases. Integrated with building management systems, they play a key role in water, steam, or gas leak maintenance.

Leaks produce distinct sounds based on pressure, material, and fluid type. Piezoelectric transducers capture these sounds, differentiating leaks from normal operational noise. This technology is particularly effective for water and gas pipelines.

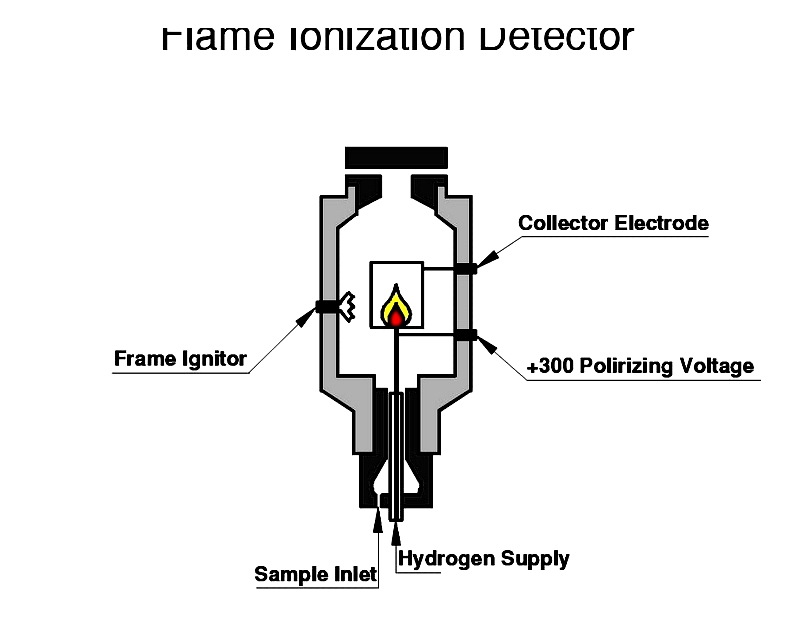

Flame Ionization (FID) Detection Device

FID detectors measure organic compounds and vapors at ppm to ppb levels. They combust samples in a hydrogen flame, ionizing substances for trace-level hydrocarbon detection in petrochemical and storage facilities.

Fluorescent Leak Detection

This method uses UV-compatible dyes to locate leaks in systems like refrigeration or hydraulics. Technicians introduce the dye, then scan with UV light to pinpoint leaks quickly.

The dye circulates with the fluid, marking leaks for easy identification. Safe for system materials, it supports ongoing maintenance programs across industries.

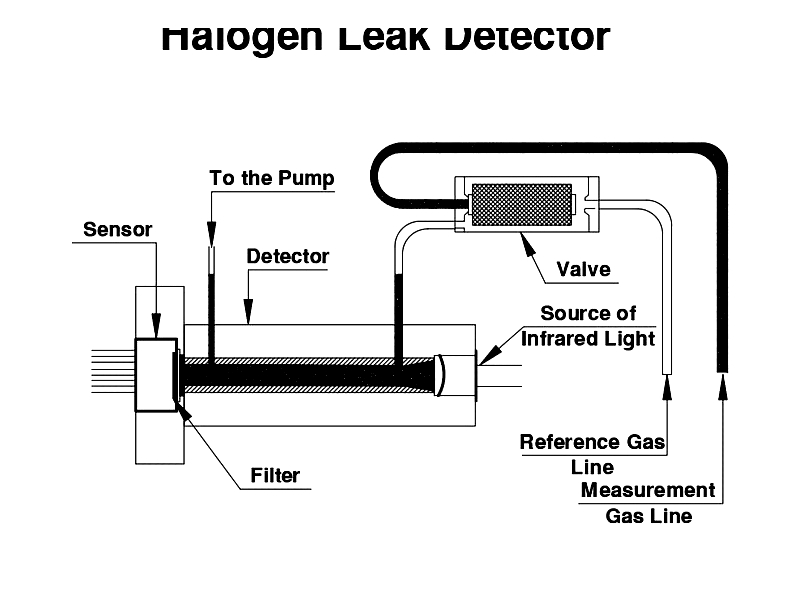

Halogen Leak Detector

These detectors identify halogenated refrigerants using chemical or heated diode sensors. While traditional flame tests show color changes, electronic sniffers offer better accuracy for low leak rates.

Environmental regulations often mandate continuous monitoring to prevent ozone depletion from refrigerants.

Helium Leak Detector

Helium detectors provide ultra-sensitive leak detection for high-purity systems. Using mass spectrometry, they detect leaks as small as 1×10-12 mbar·L/s, ideal for semiconductor and aerospace applications.

Helium's inert properties make it perfect for vacuum and pressure testing, though dry conditions are required for optimal performance.

High Voltage (HVLD)

HVLD identifies micro-defects in non-conductive packaging by applying high voltage. It detects pinholes as small as 2 microns, crucial for pharmaceutical and sterile packaging.

This method requires insulating materials capable of withstanding voltage discharge.

Hydrogen Leak Detector

Using a safe hydrogen-nitrogen mix, these detectors quickly identify leaks in automotive and industrial systems. Hydrogen's rapid diffusion enables fast testing with minimal false positives.

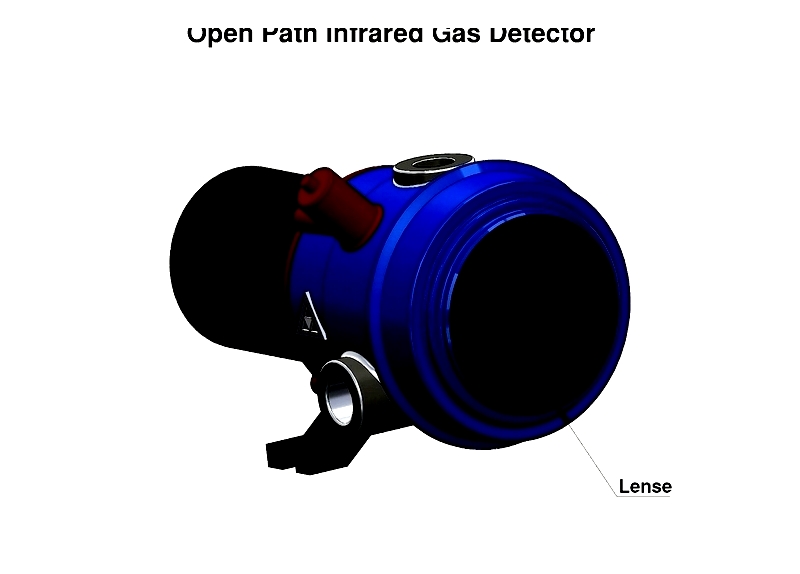

Infrared Open Path Gas Leak Detector

These systems monitor large areas for combustible or toxic gases using infrared beams. They integrate with control platforms for real-time monitoring in oil & gas and chemical plants.

Pressure Decay

This method measures pressure drops to identify leaks in sealed components. It's widely used in automotive and medical device industries for its simplicity.

- Differential or Vacuum Decay - Compares test samples to references under vacuum.

- Occlusion - Checks for flow blockages.

- Burst - Tests maximum pressure tolerance.

- Crack Pressure - Verifies valve opening pressures.

- Ch