Introduction

This article provides an in-depth exploration of metal Injection Molding.

Continue reading to learn about key topics including:

- The fundamentals of metal Injection Molding

- Key stages in the metal Injection Molding process

- Benefits and limitations of metal Injection Molding

- important considerations for metal Injection Molding

- And much more...

Chapter 1: Understanding metal Injection Molding

metal Injection Molding (MIM), also called powder injection molding (PIM), is an advanced manufacturing process that creates solid metal parts using injection molding technology. Originally developed for ceramic materials, this innovative method was adapted for metal applications in the 1970s by Raymond Wiech. Since the 1990s, MIM has become widely adopted in metal manufacturing.

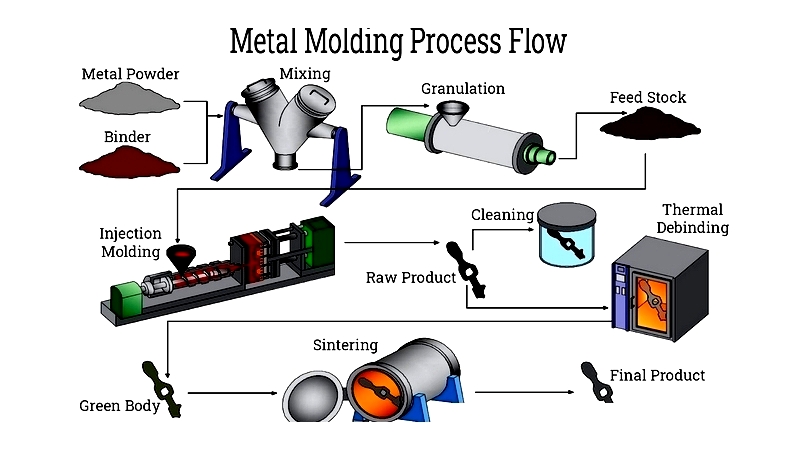

The MIM process combines fine metal powders with a plastic binder to create feedstock suitable for injection molding. This mixture is melted, shaped, and cooled using standard molding equipment. After molding, parts undergo binder removal and sintering to eliminate the plastic binder and enhance metal density and strength. These steps ensure the final components meet required specifications for geometry, composition, and physical properties.

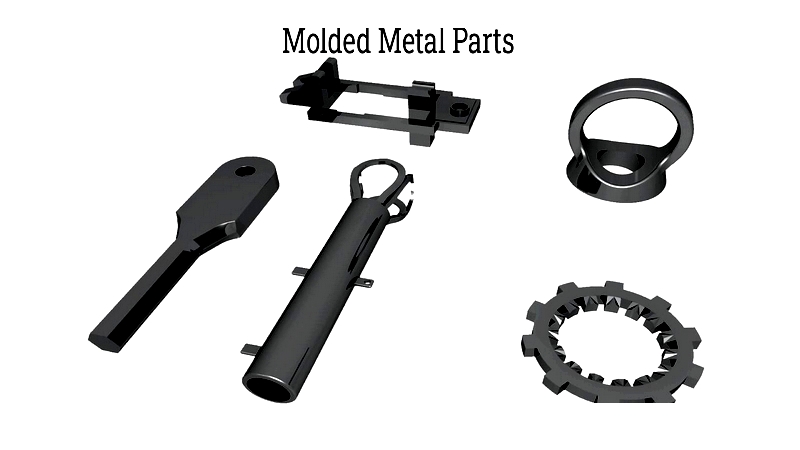

MIM excels at producing large quantities of small, complex parts with intricate features. It enables precise manufacturing without additional machining. The process works with various ferrous and non-ferrous metals and typically offers cost advantages over traditional methods like casting and forging. MIM components serve diverse industries including automotive, aerospace, medical, and consumer products where precision and complexity are crucial.

Chapter 2: Key Stages of the metal Injection Molding Process

The metal injection molding process (MIM) is a sophisticated manufacturing technique that produces complex, precision metal components with properties comparable to traditional methods. Industries like automotive, aerospace, and medical devices favor MIM for its efficiency, quality, and cost-effectiveness in producing intricate parts. The core MIM process stages include:

Feedstock Mixing

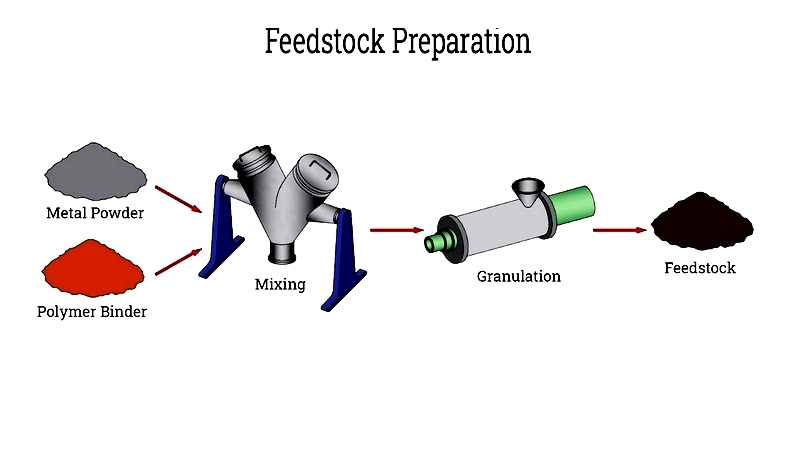

The initial stage involves feedstock preparation, where fine metal powder (such as stainless steel or titanium alloys) is blended with a thermoplastic binder to create feedstock. This uniform mixture is critical for achieving desired mechanical properties and dimensional accuracy. The binder system performs several important functions:

- Adjusts feedstock viscosity to ensure proper flow for filling complex molds

- Provides cohesion and strength to maintain part shape after molding

- Facilitates clean release from precision tooling

The binder system typically contains:

- Lubricants/plasticizers for improved flow

- Backbone polymers for structural stability

- Surfactants to prevent powder clumping

Complete binder removal is essential for final part quality. Ideal binder characteristics include:

- Easy decomposition or solubility

- Compatibility with metal powders

- Recyclability and environmental safety

During preparation, manufacturers carefully blend fine metal powders (typically 20 microns) with binder at a 60:40 ratio. The resulting homogeneous mixture is granulated and pelletized for use in injection molding machines.

Injection Molding

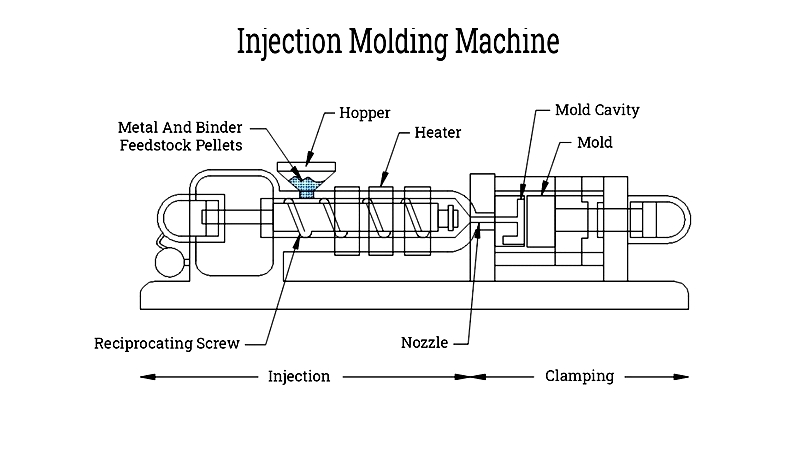

The injection molding step uses specialized MIM machines to melt and inject feedstock into precision molds. These molds replicate complex geometries that would be difficult or expensive to machine. Since sintering causes 15-25% shrinkage, molds are intentionally oversized. The resulting "green parts" are fragile but contain the desired shape and features.

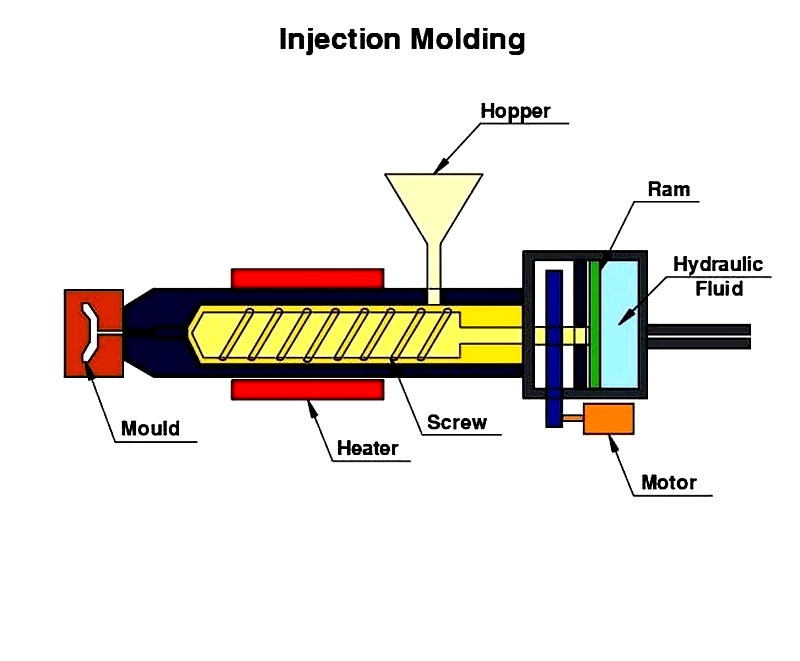

A MIM injection molding machine consists of key components:

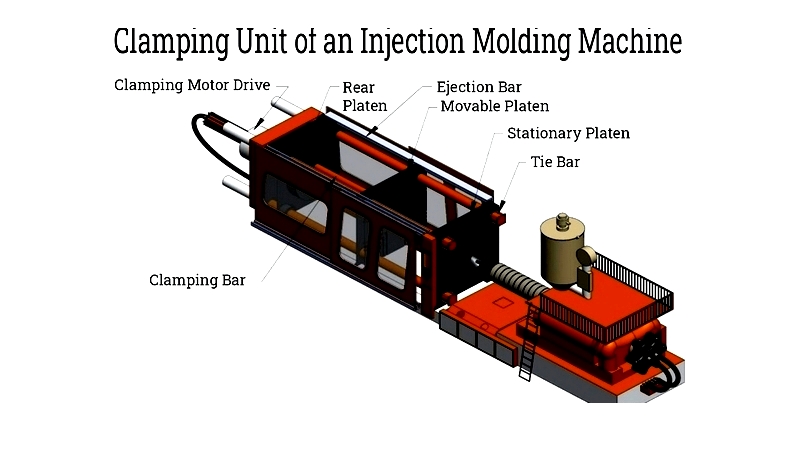

Clamping Unit

The clamping unit applies force to keep molds closed during injection and cooling, while ensuring precise alignment for precision metal injection molding.

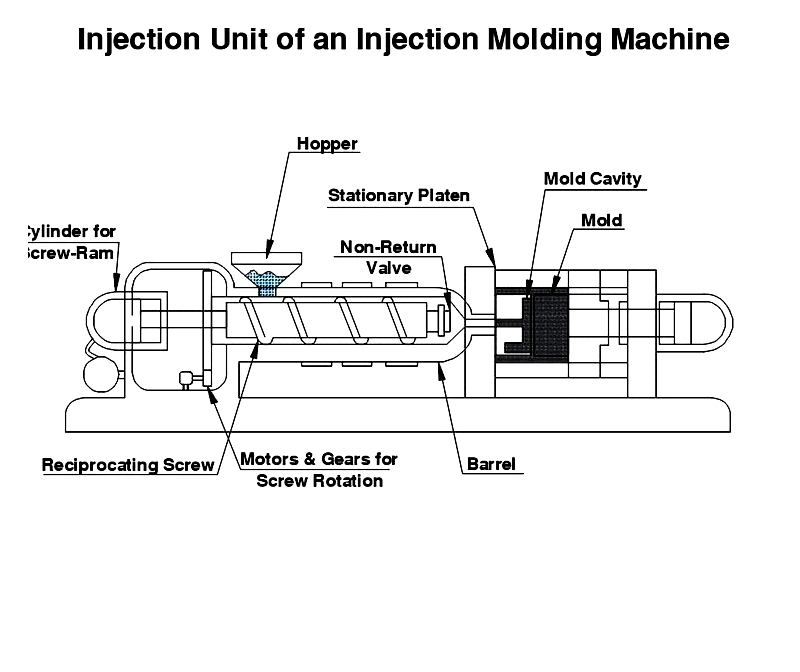

Injection Unit

The injection unit melts and injects feedstock, containing:

- Hopper: Feeds pellets consistently

- Barrel: Houses heating elements and screw

- Injection Screw: Mixes and delivers molten feedstock

- Nozzle: Connects to mold for precise delivery

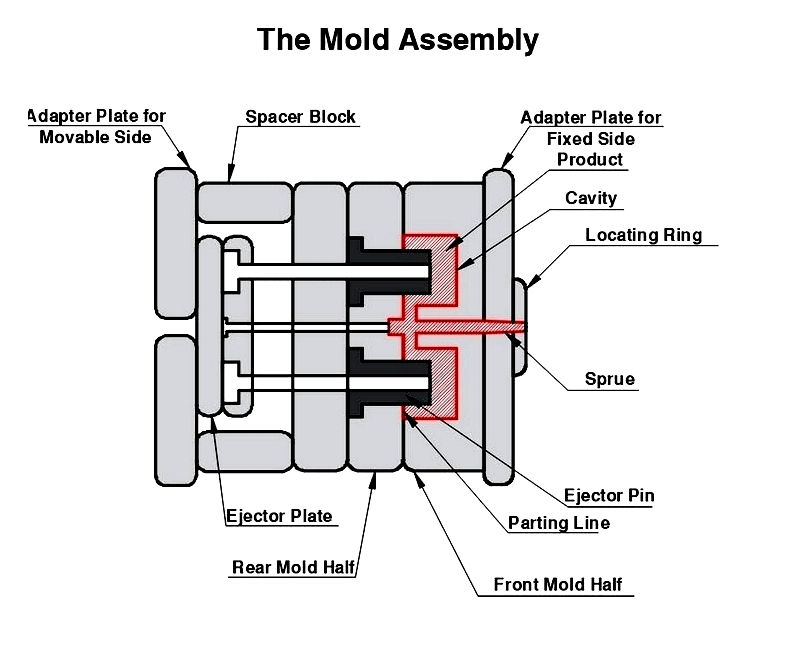

Mold Design

The MIM mold shapes each part with precision. Design considerations include runner systems, cooling channels, and venting to ensure quality and efficiency. Proper mold engineering prevents defects and maintains tight tolerances.

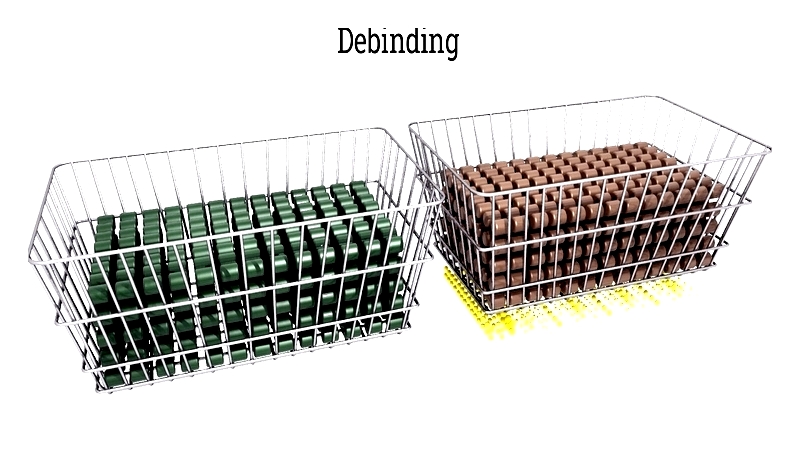

Debinding

Debinding removes most organic binders, creating porous "brown parts" that retain some binder for structural support. The process can use thermal, solvent, or catalytic methods depending on requirements.

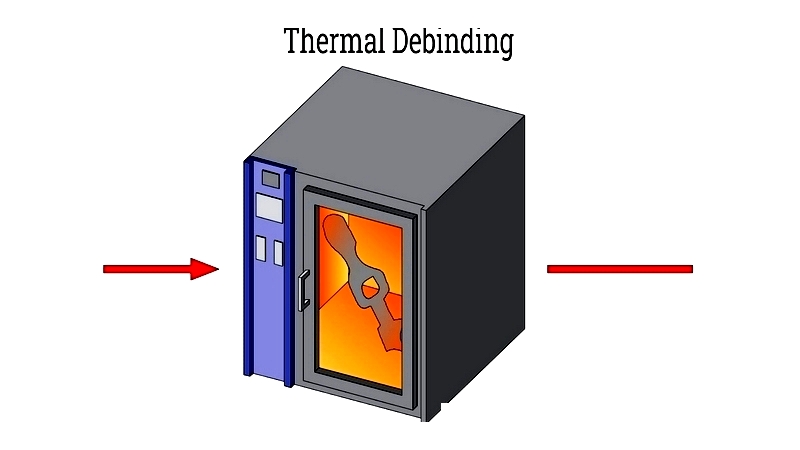

Thermal Debinding

Thermal debinding uses controlled heating to remove binders, often requiring extended processing times.

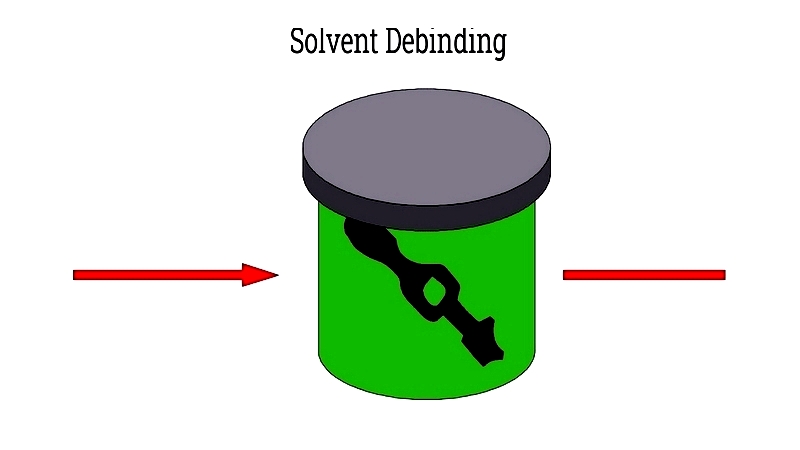

Solvent Debinding

Solvent debinding employs chemical baths for faster processing with lower thermal impact.

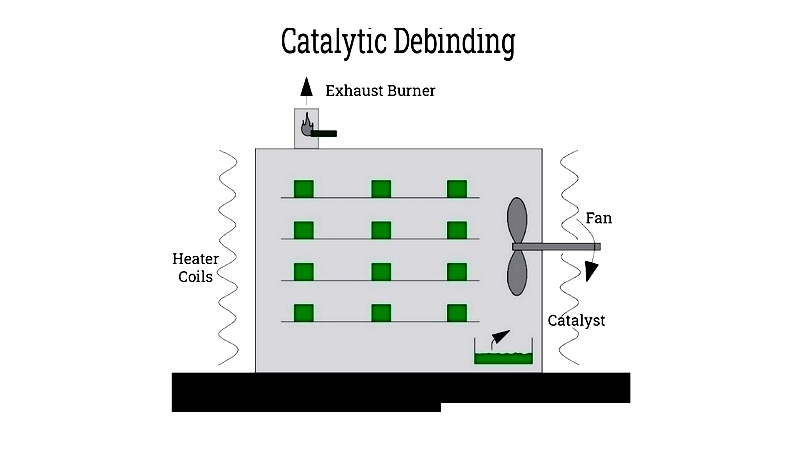

Catalytic Debinding

Catalytic debinding uses acid gases for rapid binder removal in specific applications.

Sintering Process

Sintering transforms brown parts into final products by heating them near melting point in controlled atmospheres