Introduction

This article provides an in-depth exploration of fiberglass sheets.

You'll gain insights into various aspects including:

- What Fiberglass Sheets Are

- Key Properties of Fiberglass

- Different Types of Fiberglass

- Applications and Uses of Fiberglass

- Advantages and Disadvantages of Fiberglass Sheets

- And Much More...

Chapter 1: What is a Fiberglass Sheet and the Manufacturing Process?

Fiberglass sheets consist of fine glass fibers reinforced with plastic, known for their exceptional tensile strength and resistance to corrosion, fire, and chemicals like organic solvents, bleach, and acids. Their primary advantage lies in the remarkable strength-to-weight ratio achieved through fiber reinforcement and even weight distribution by the plastic matrix. These sheets are available in thicknesses ranging from 1.5 mm to 75 mm.

Composition of Fiberglass

Fiberglass combines glass fibers with a resin matrix. While the basic structure remains consistent, variations occur in material proportions and types. Key components include silica sand, soda ash, and limestone, along with additives like borax, calcined alumina, magnesite, kaolin clay, and feldspar. Silica sand forms the glass fiber foundation, while soda ash and limestone lower the melting point. Additional additives modify specific properties to enhance performance characteristics.

Chapter 2: How Fiberglass Panels and Sheets are Made

Fiberglass sheet production begins with creating the fiberglass material itself. Although proprietary methods exist, the fundamental process involves forming glass fibers. These lightweight, durable materials find extensive use in construction, industrial, marine, and automotive applications due to their strength-to-weight ratio and corrosion resistance. Understanding the manufacturing process helps in selecting appropriate composite materials based on load-bearing capacity, flexibility, and weather resistance.

The manufacturing process involves extrusion, where molten material passes through a bushing. Raw materials are melted and extruded through spinnerets with 200 to 3000 fine orifices. As filaments emerge, they're coated with resin for shaping and solidification, creating reinforced composite panels used in building insulation, wall cladding, and translucent roofing.

Two main filament types exist: continuous and staple. These filaments receive a chemical finish coating and are gathered into rovings. The glass fiber weight (yield) depends on filament count and thickness in each roving, influencing the final product's structural integrity, flexibility, and suitability for various applications.

Batching of Fiberglass

The initial manufacturing stage involves batching - preparing raw materials for furnace feeding. Materials must be precisely weighed, mixed, and transported using automated systems with computerized weighing. Accurate batching ensures consistent mechanical properties and quality, particularly important for structural applications.

Melting of Fiberglass

After batching, materials enter the furnace for melting. Heating occurs through electricity, fossil fuels, or both, with precise temperature control crucial for smooth molten glass flow and product quality.

The furnace comprises three sections: melting/homogenizing, refining (cooling), and the fire hearth containing bushings for fiber extrusion. This process achieves the homogeneity and durability required for FRP panels and architectural composites.

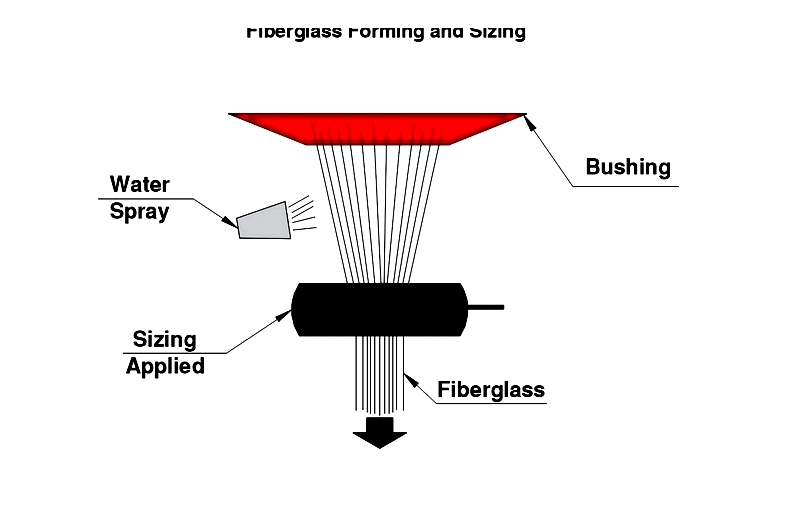

Fiber Formation

Fiberization transforms molten glass into fibers through extrusion and attenuation. Molten glass passes through platinum/rhodium alloy bushings, cooled by water jets to create uniformly sized fibers optimized for resin reinforcement.

Attenuation draws molten streams into filaments (4-34 µm diameter) using high-speed winders. Filament diameter and uniformity directly affect tensile strength, dimensional stability, and chemical resistance of final products.

Continuous Filament Process

This method produces indefinite-length filaments wound at high speeds into fiberglass yarn, ideal for structural sheets, FRP, and applications requiring maximum strength and consistency.

Staple-Fiber Process

Compressed air jets convert molten material into long, thin fibers collected into slivers and woven into yarn, commonly used for insulation and lightweight panels requiring flexibility.

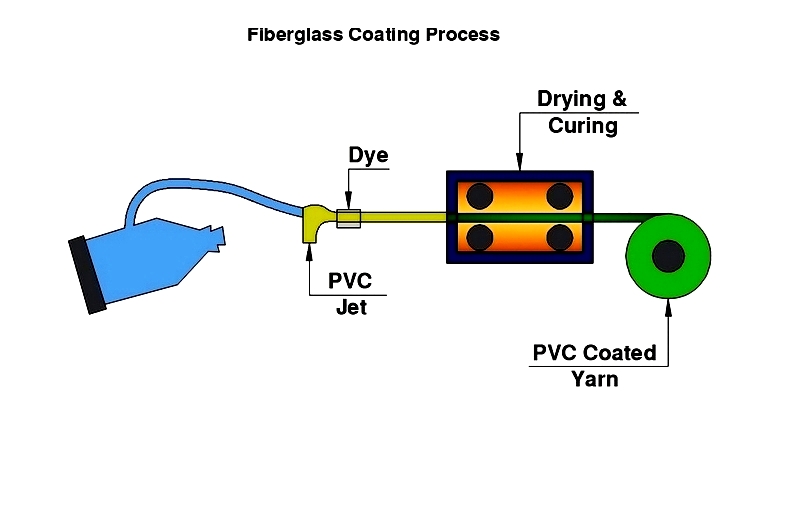

Coating of Fiberglass

The final stage applies chemical coatings (0.5-2.0% by weight) including binders, lubricants, and coupling agents. Lubricants minimize filament abrasion during collection and winding.

Fabrics are created using weaving machines, with coupling agents enhancing fiber-resin adhesion for better penetration. Sizing chemistry determines compatibility with epoxy or polyester resins, while lubricants reduce abrasion. Optimized coatings improve chemical resistance, impact strength, and product lifespan.

Unwoven Fiberglass Mats

Fiber Dispersion

Processed fibers create nonwoven mats for sheet production. Fiber length and diameter affect mat performance, with long, large-diameter fibers differing significantly from short, small-diameter ones. Nonwoven mats suit flat sheets, skylights, and GRP laminates due to uniformity and low resin consumption.

Fibers disperse in a pulping system using whitewater chemistry to maintain suspension without clumping, ensuring quality matting for construction, agriculture, and transportation applications.

Mat Forming

A closed-loop water system spreads fibers evenly across mat forming machines. Machine adjustments control final mat properties, with fiber orientation significantly impacting surface quality and strength for panels, ceiling tiles, and facade systems.

Binding

Formed mats require binders for strength. Modern binders are formaldehyde-free and bio-based, with options ranging from cloth-soft to rigid for laminates. Eco-friendly binders are prioritized for green buildings and cleanroom applications.

Drying

This phase removes water and cures binders. Controlled drying prevents warpage and ensures performance in moisture or temperature-variable environments like exterior panels and roofing sheets.

Woven Fiberglass

Woven fiberglass forms dense cloth through interlacing warp and fill threads. Primary techniques include twill and satin weaves, offering strength, formability, and crack resistance for aerospace, marine, and architectural applications.

Satin weaves pass fill yarn over multiple warp threads for strength, while twill weaves balance strength and flexibility. Weave selection affects appearance, impact resistance, and workability for construction or factory settings.

Woven Roving Fiberglass

Continuous filament woven roving adds laminate thickness. Its rough texture requires mat fiberglass layers between sheets for heavy-duty applications like industrial panels and aerospace components.

Making Fiberglass Panels and Sheets

Fiberglass production yields various products, with fiber type determining thickness and weight. Material and process selection is crucial, considering fire resistance, chemical durability, impact strength, and lifecycle cost for specific applications.

Pultrusion creates panels and sheets by pulling materials through resin mixtures (polyester, epoxy, or vinylester) with fillers and reinforcing fibers. This continuous process ensures uniform thickness and smooth finishes for architectural and industrial uses.

During pultrusion, resin-saturated mats pass through heated dies for curing into rigid profiles. Variations accommodate different geometries, with product evaluation based on thickness, surface finish, insulation values, and UV protection.

Exiting the resin impregnator, materials are shaped in preformers before die curing. Post-curing processes include cutting, cooling, and finishing (trimming, sanding