Introduction

This article provides a comprehensive overview of air dryers.

Continue reading to explore key topics including:

- What is an air dryer?

- Dew point and relative humidity

- The importance of air dryers

- Types of air dryers and their working principles

Chapter 1: Understanding Air Dryers

An air dryer is a specialized device designed to remove moisture from air, particularly in compressed air systems. Ambient air typically has a relative humidity between 30% and 50%. However, when air is compressed, its moisture content increases within the confined space, raising the relative humidity to 100% and causing excess water to condense.

Excessive moisture can negatively impact equipment performance and lifespan, leading to issues such as process stream contamination, premature equipment failure, accelerated part wear, and machinery corrosion.

Moisture removal isn't exclusive to compressed air processes. Various industrial and manufacturing operations also require moisture extraction, including dewatering, baking, industrial drying, food dehydration, steam heating, and cleaning. These processes use different dryer types primarily focused on drying, solidifying, and purifying materials through moisture removal, employing heat transfer principles like conduction, convection, and radiation. Air drying distinguishes itself by using methods such as refrigeration, adsorption, absorption, diffusion, and filtration.

Chapter 2: Dew Point Temperature and Relative Humidity

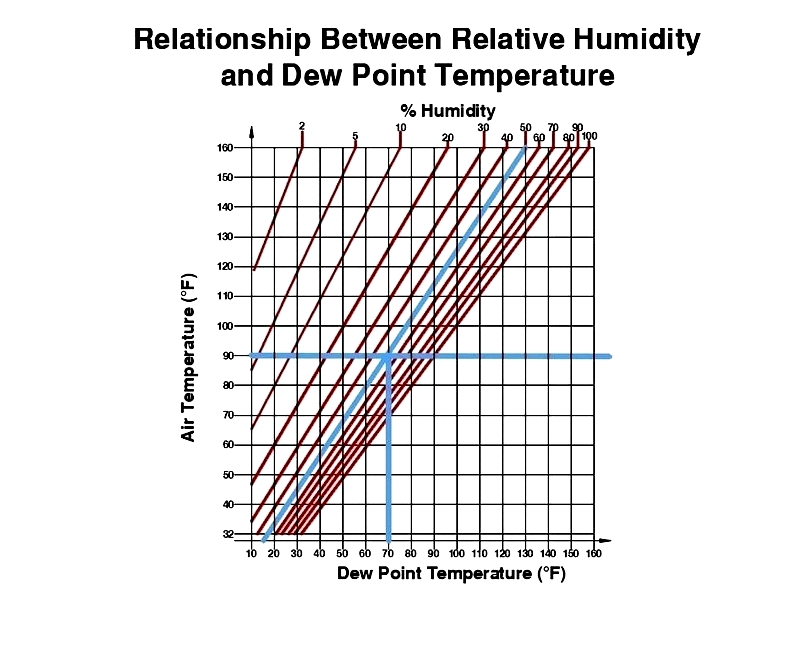

The dew point temperature is crucial in climate control, HVAC systems, and industrial drying processes. It represents the temperature at which air becomes saturated with water vapor, causing moisture to condense into liquid. In industrial settings, this leads to condensate formation on equipment surfaces, pipe walls, tank interiors, or finished products. Understanding dew point is essential for applications like compressed air dryers, desiccant dryers, and refrigerated dryers, where minimizing moisture content is vital for product quality and equipment longevity.

Relative humidity (RH) measures the current water vapor in air relative to its maximum capacity at a specific temperature. Expressed as a percentage, RH helps gauge comfort, prevent corrosion, and control biological growth like mold. In manufacturing, maintaining lower RH levels prevents unwanted condensation and protects sensitive components. When RH reaches 100%, the air is fully saturated, and any additional vapor or temperature decrease causes condensation at the dew point temperature.

While RH can be adjusted by changing air temperature, the absolute water vapor content and dew point remain constant unless moisture is physically added or removed. This distinction is critical in food processing, pharmaceuticals, and chemicals, where precise humidity control and moisture removal ensure product integrity and regulatory compliance.

Monitoring dew point temperature accurately indicates air quality and moisture load in industrial drying environments. Higher dew points mean more water vapor retention, increasing condensation risks that can compromise industrial drying equipment efficiency and product quality. For example, a drying system consistently achieving a 3°C (37°F) dew point demonstrates effective moisture removal. Facility managers often use dew point meters and humidity sensors to optimize operations for energy efficiency and moisture control.

Air pressure also affects dew point temperature. Pressurized air, as in pneumatic systems, increases dew point since air's moisture-holding capacity changes. Professionals refer to pressure dew point when discussing dew points under non-standard pressures. Proper pressure dew point management in compressed air systems prevents corrosion, instrument failure, and product spoilage from condensation.

Selecting the right air dryer depends on understanding both dew point and relative humidity. Desiccant dryers achieve ultra-low dew points for sensitive applications, while refrigerated dryers suit general industrial use with moderate humidity control. Customizing air treatment based on accurate measurements enhances performance while reducing energy costs and maintenance needs.

Chapter 3: The importance of Air Dryers

Air dryers are essential components in industrial compressed air systems. Compressing air also compresses water vapor, leading to moisture buildup and condensation throughout the system. Without effective dryers, water accumulation can severely impact operations, increase maintenance, and shorten equipment lifespan. Properly sized and installed dryers—including refrigerated, desiccant, membrane, and regenerative types—offer critical benefits for industries relying on clean, dry compressed air.

Removing Water Contamination

Water contamination is a major issue in industries requiring high-purity compressed air, such as laser cutting, microelectronics, food processing, pharmaceuticals, and painting. Contaminants like water, oil, and particulates can cause product defects, equipment malfunctions, and reduced efficiency. For example, in laser cutting, moisture-contaminated compressed air can lead to inefficient cooling, overheating, and system shutdowns. Air dryers help remove harmful vapor and meet ISO 8573 air quality standards.

Preventing Water Buildup

Compressed air systems naturally carry water vapor that condenses when temperatures drop or pressure increases. This condensation can pool in piping, air receivers, or control lines, causing issues for precision instruments, sensors, and pneumatic valves. Effective dryers minimize water carryover, protecting downstream equipment and reducing maintenance needs.

Reducing Corrosion

Moisture accelerates corrosion in metallic components like pipes, tanks, and mixing equipment. This degradation can contaminate products, clog air lines with rust, and impact regulatory compliance. Desiccant or refrigerated dryers significantly reduce this risk, extending equipment lifespan.

Preventing Freezing

In cold environments, unremoved water vapor can freeze in pipelines, valves, or actuators, causing blockages and safety hazards. Dryers designed for low dew points, like regenerative desiccant types, protect against freeze-ups in freezing temperatures.

Enhancing Equipment Efficiency

Dry, oil-free air is critical for the performance and longevity of pneumatic tools and automated systems. Water contamination increases friction, wear, and failure rates in cylinders, motors, and drills. Quality dryers improve performance, lower repair costs, and maximize uptime in manufacturing, construction, and automotive industries.

Inhibiting Microbial Growth

In food, pharmaceutical, and packaging industries, sterile compressed air is essential. Residual moisture promotes bacteria, mold, and yeast growth, threatening product integrity and compliance. Specialty dryers like membrane or high-efficiency desiccant types remove both moisture and microorganisms, ensuring air quality in production lines and cleanrooms.

Choosing the Right Dryer

Selecting an air dryer requires considering dew point requirements, system capacity, ambient conditions, power efficiency, and compatibility with existing