Introduction

This article provides detailed information about flat belts.

It covers the following topics:

- What are flat belts?

- Types of flat belts

- Materials used in flat belt production

- Applications of flat belts

- Advantages and disadvantages of flat belts

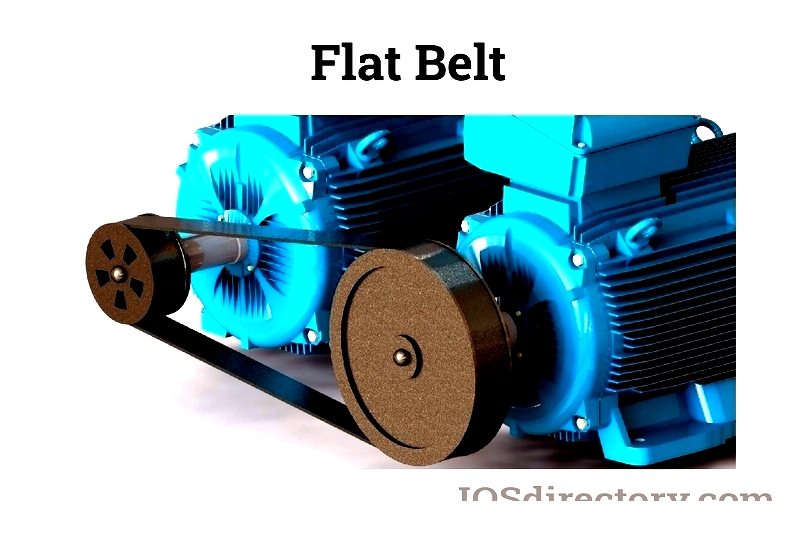

Chapter 1: What are Flat Belts?

Flat belts are essential power transmission components made from materials like rubber, synthetic composites, or leather. They efficiently transfer rotational power in industrial machines and conveyor systems. Their low-profile design and secure grip make them ideal for high-speed applications.

With their flat trapezoidal cross-section, these belts minimize slippage and improve power transmission efficiency. Manufactured with rubber and reinforcing fibers, they come in various sizes and strengths to meet different application needs.

Chapter 2: Types of Flat Belts

Flat belts serve as versatile power transmission components in industrial and commercial applications due to their efficiency and cost-effectiveness. This chapter examines major flat belt types, their features, materials, and selection criteria. Understanding these differences helps professionals make informed decisions to enhance productivity and reduce downtime.

Common flat belt types include:

Rubber Belts

Originally developed as leather belt alternatives, rubber flat belts were later overshadowed by V-belts due to tracking issues. Modern advancements in rubber compounds and reinforcement techniques have improved their performance. Today's rubber flat belts offer excellent elasticity, abrasion resistance, and grip, making them suitable for high-speed and heavy-duty applications.

Their popularity stems from high mechanical efficiency (over 98%) and minimal bending loss. Compared to V-belts, they experience less wear and are available in various widths for specialized uses like packaging systems. Requiring less maintenance and operating quietly, they're preferred where energy efficiency and reliability matter.

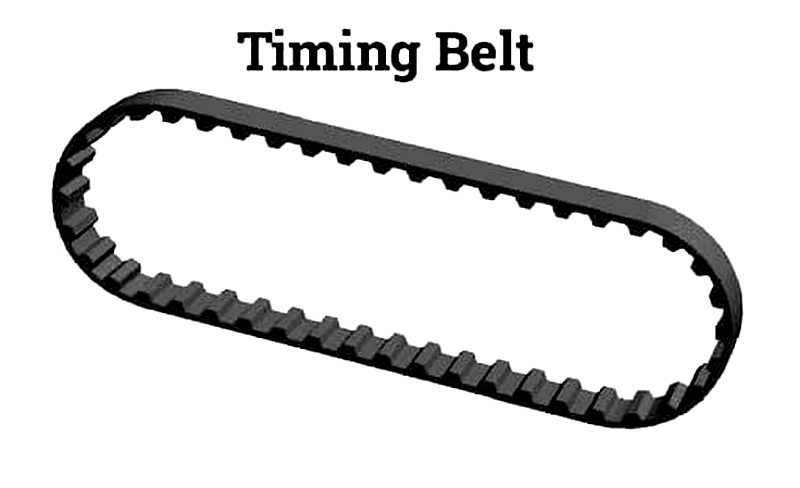

Timing Belts

Featuring rubber teeth for precise grip, timing belts ensure accurate synchronization in machinery. They're crucial for maintaining performance in conveyor automation, textile machines, and automotive engines where misalignment causes problems.

Made from natural rubber or synthetics like neoprene and polyurethane, these belts incorporate reinforcing cords (fiberglass, Kevlar, or steel) for strength. Their teeth mesh securely with pulleys, eliminating slippage in applications requiring precise positioning.

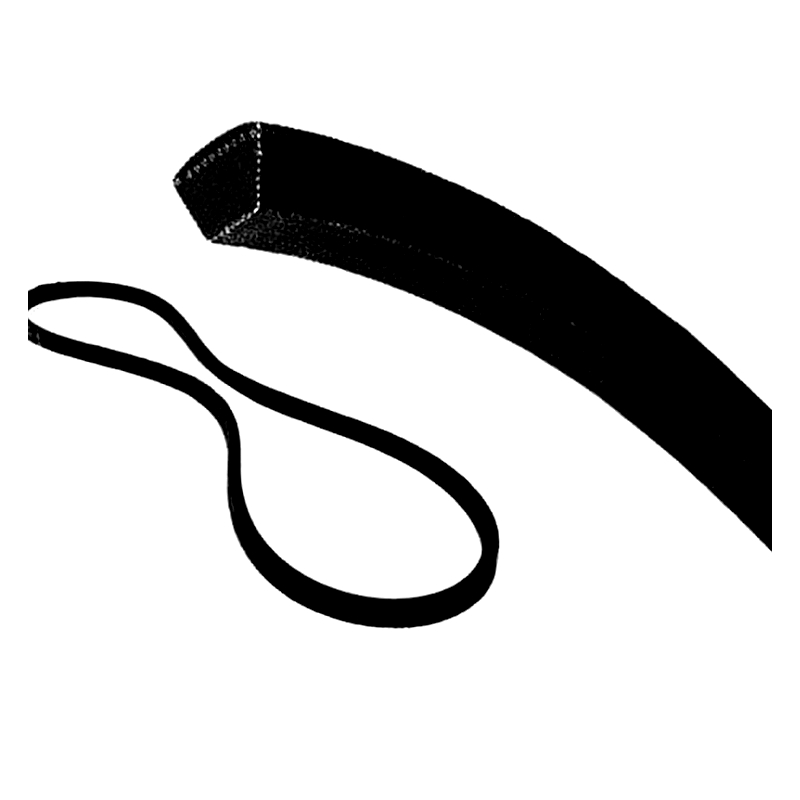

V-Belts

V-belts have a trapezoidal cross-section that prevents slippage by increasing pulley contact area. Their design makes them reliable for high-torque applications requiring shock absorption.

Constructed with rubber and reinforcing cords (polyester or aramid), they're often fabric-covered for protection. Widely used in HVAC systems, industrial conveyors, and agricultural equipment for their versatility.

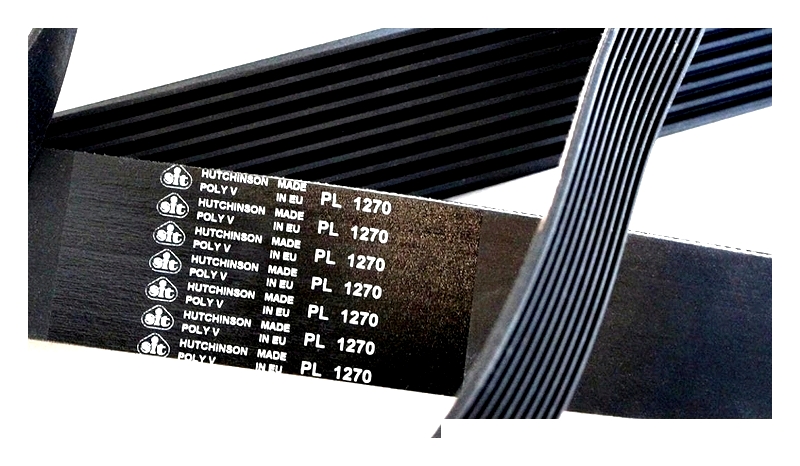

Poly-V Belts

Also called multi-ribbed belts, these feature multiple V-shaped ribs for enhanced grip. The ribs ensure balanced tension and torque transfer while allowing tighter pulley bends.

Their flexibility and power capacity make them popular in automotive engines and industrial equipment.

Wedgelock Belts

A specialized V-belt variant with steep walls for improved load-bearing. Their design minimizes slippage and side movement in demanding industrial applications.

Made from premium rubber compounds, they excel in mining equipment and critical power systems.

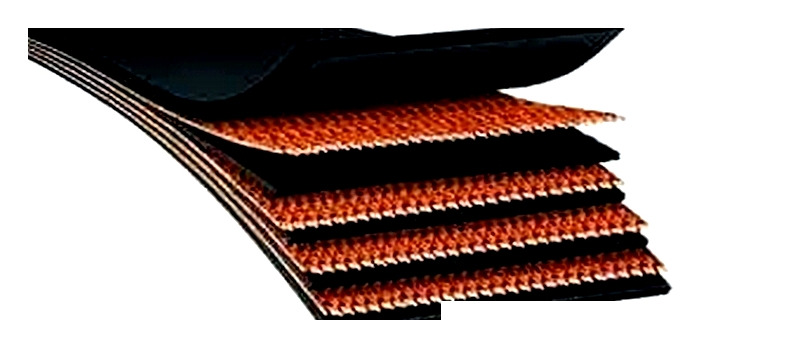

Fabric Ply Belts

Multi-layered fabric belts offering high tensile strength for conveyors and elevators. Synthetic fiber reinforcement enhances stretch resistance and durability.

Fabric Cord Belts

Similar to fabric ply belts but with parallel cords for added strength. Ideal for high-tension applications requiring dimensional stability.

Synthetic Flat Belts

Made from advanced materials like polyurethane, these resist wear and environmental factors. Used in food processing and pharmaceuticals where hygiene matters.

Selection depends on load requirements, environmental conditions, and industry standards. Consultation with suppliers ensures optimal performance.

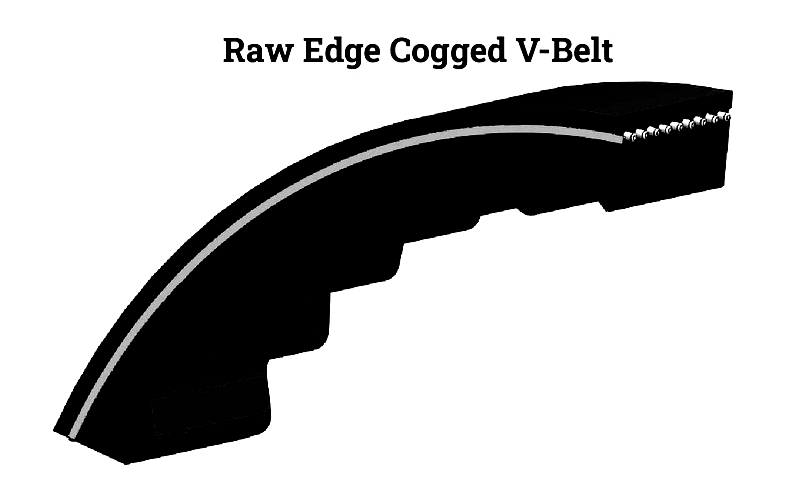

Raw Edge Belts

Designed for maximum grip in high-torque applications. Their uncoated edges allow tighter pulley radii and efficient power transfer.

Flat Wrapped Belts

Fabric-covered belts offering enhanced durability in high-stress environments. The wrapping protects against friction and extends service life.

Leather Belts

Early industrial belts still used in specialty applications. Their flexibility suits vintage machinery and low-noise operations.

Choosing the Right Flat Belt

Consider load requirements, speed, environmental factors, and maintenance needs when selecting belts. Manufacturers offer customized solutions to optimize performance and reduce costs.

For specific applications, consult knowledgeable suppliers who can provide tailored recommendations.