Introduction

This article provides a comprehensive examination of anodized aluminum.

Continue reading to learn about:

- What is Anodized Aluminum?

- The Aluminum Anodizing Process

- Types of Anodized Aluminum Finishes

- And more...

Chapter 1: What is Anodized Aluminum?

Anodized aluminum undergoes an electrochemical treatment that creates a durable, corrosion-resistant, and visually appealing surface. This process forms an anodic layer directly on the aluminum's surface through a series of baths. The resulting layer bonds with the aluminum, preventing chipping, peeling, or flaking. Anodized aluminum is approximately three times more durable than untreated aluminum and lighter than stainless steel or copper.

The anodizing process produces a strong aluminum oxide layer that enhances hardness and strength. This porous layer allows for dye, paint, lubricant, and adhesive application while improving corrosion and wear resistance for harsh environments.

The anodized layer chemically bonds with the aluminum, resisting chipping, peeling, and scratching. Its porous structure accepts various treatments while offering superior protection against weathering.

Anodizing maintains aluminum's recyclability and is more environmentally friendly than electroplating or painting. The process creates a glossy finish that enhances appearance and allows for vibrant, fade-resistant colors, making it popular for decorative and architectural applications.

Chapter 2: The Aluminum Anodizing Process

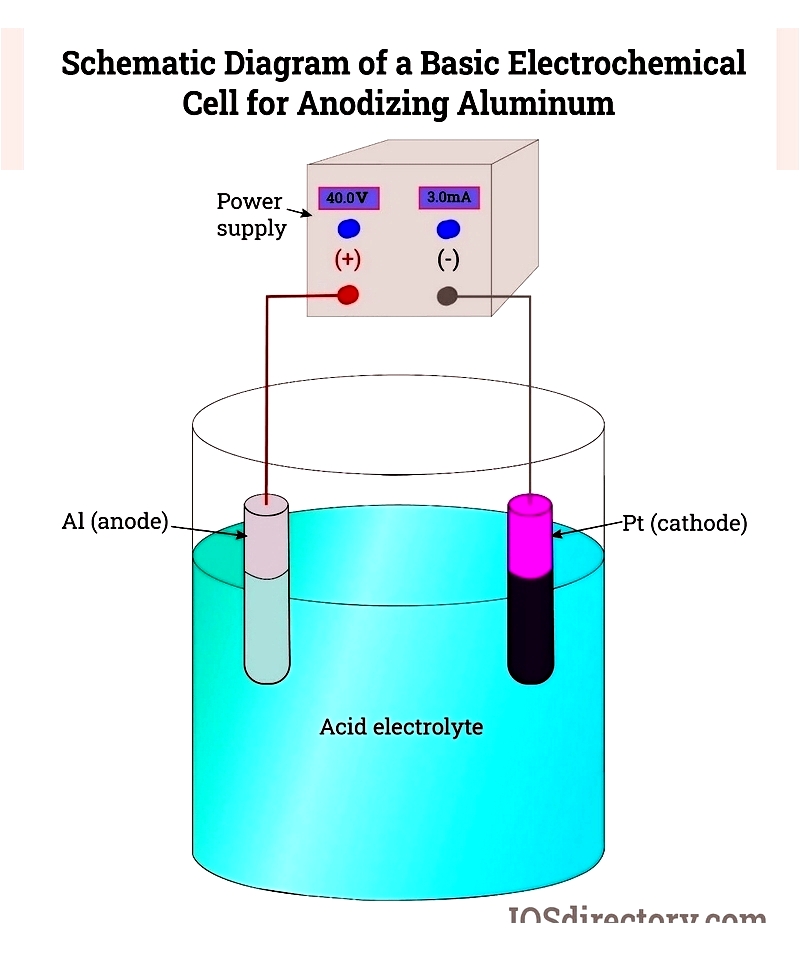

Anodizing increases the natural oxide layer's thickness through electrolytic passivation. This involves immersing aluminum in an acidic electrolyte bath and applying direct current to promote oxidation.

During anodizing, aluminum acts as the anode while a cathode (typically platinum, stainless steel, lead, or carbon) completes the circuit. Voltage application causes positive ion release and negative ion attraction, forming a protective aluminum oxide layer.

While primarily used for aluminum, anodizing can also treat magnesium, zinc, titanium, and some conductive plastics. It's unsuitable for ferrous metals like carbon steel, which form rust instead of stable oxide films.

Anodizing methods include:

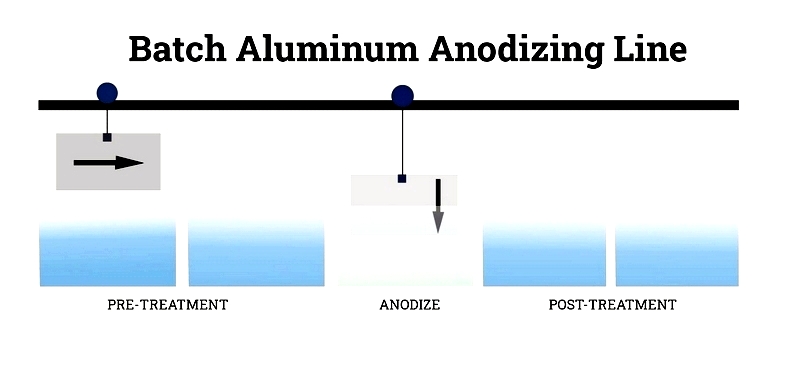

- Batch anodizing: Items are racked and processed through sequential baths, ideal for cookware, castings, and machined components.

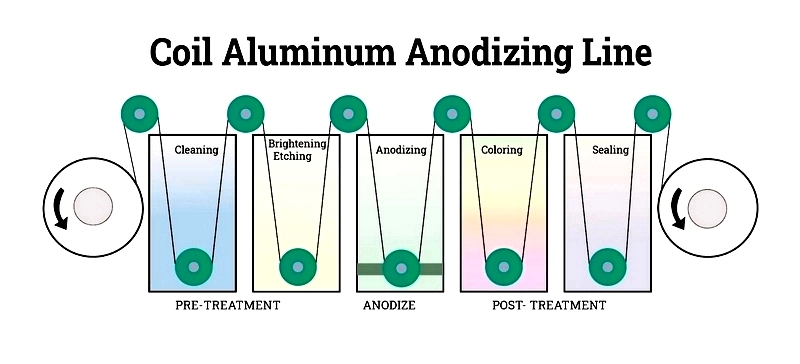

- Continuous anodizing: Pre-rolled material moves continuously through the process, suitable for wires, plates, sheets, and foils.

1. Pre-Treatment

Pre-treatment removes contaminants and prepares the surface through chemical or mechanical methods:

Chemical Pre-Treatment

Chemical cleaning uses acid or alkali solutions to remove dirt and grease, followed by etching or brightening:

- Etching: Creates a matte finish by removing surface layers with sodium hydroxide or ammonium bifluoride.

- Brightening: Produces a reflective surface using phosphoric or nitric acid baths.

Mechanical Pre-Treatment

Methods like abrasive polishing and sandblasting improve fatigue resistance and coating adhesion.

2. Electrolysis

This core process immerses aluminum in an electrolyte bath with DC current, forming an aluminum oxide layer through electrochemical reactions.

2Al³⁺ + 3O²⁻ → Al₂O₃

2Al³⁺ + 3OH⁻ → Al₂O₃ + 3H⁺

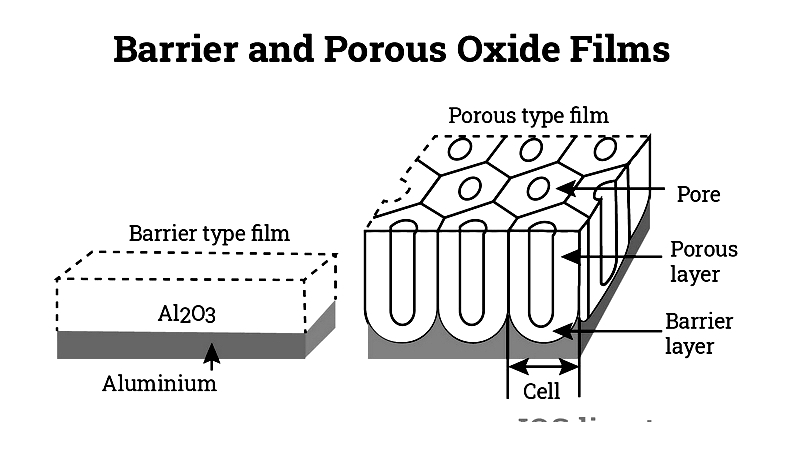

Electrolysis produces either barrier or porous oxide films depending on electrolyte composition.

3. Barrier Oxide Film

Forms in neutral solutions, creating a robust, non-reactive protective layer whose thickness depends on applied voltage.

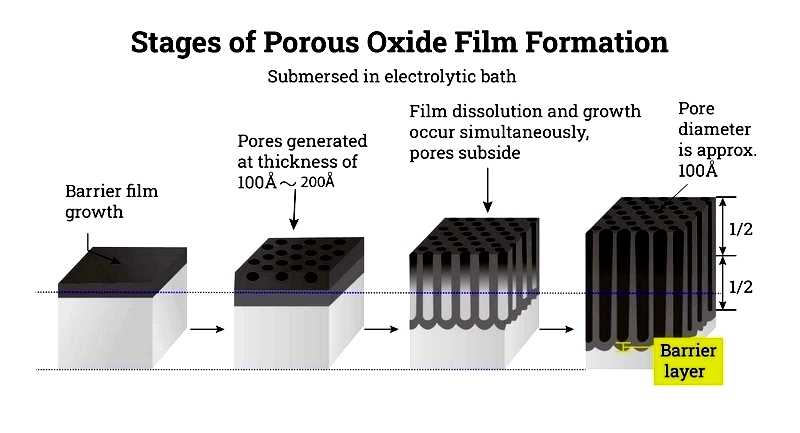

4. Porous Oxide Film

Develops in dilute acidic solutions (typically 10% sulfuric acid), with thickness controlled by electrolysis duration and voltage. The porous structure allows for dye absorption.

Anodizing Types

MIL-A-8625 specifies three primary anodizing processes:

Type I - Chromic Acid Anodizing

Produces thin (20-100 µin) films ideal for aerospace applications. Though effective, chromic acid's toxicity raises environmental concerns.

Type II - Sulfuric Acid Anodizing

The most common method, creating thicker (100-1000 µin), dye-absorbent films for decorative and functional uses. More cost-effective than Type I.

Type III - Hard Anodizing

Produces extremely thick (>1000 µin), durable coatings for demanding military and aerospace applications, though more expensive.

Specialty Anodizing Processes

Additional methods include:

- Boric-Sulfuric Acid Anodizing (BSAA)

- Phosphoric Acid Anodizing (PAA)

- Thin-Film Sulfuric Acid Anodizing (TFSAA)

- Clear Anodizing

- Bright Dip Anodizing

- Black Anodizing

- Color An