Introduction

This article provides an in-depth exploration of epoxy adhesives, covering key aspects such as:

- Principle of Epoxy Adhesives

- Classes and Types of Epoxy Adhesives

- Applications and Benefits of Epoxy Adhesives

- And Much More...

Chapter 1: Fundamentals of Epoxy Adhesives

This chapter offers an overview of epoxy adhesives, explaining their production process and working mechanisms.

Understanding Epoxy Adhesives

Epoxy: A thermosetting adhesive composed of epoxy polymer resin and hardener, epoxy glue creates durable bonds capable of withstanding extreme stresses and environmental conditions.

Adhesive: Refers to the process of bonding surfaces or objects.

As the most versatile structural adhesives, epoxy adhesives dominate industrial applications due to their exceptional bonding strength with various materials. These formulations can be easily customized to meet specific project requirements.

Different epoxy resins determine core adhesive properties. Heat-resistant epoxy resins suit high-temperature applications, while flexible epoxy resins accommodate movement.

Production of Epoxy Adhesives

Epoxy adhesives are produced through resin and hardener polymerization. While epoxy resin and curing agents form the primary components, additional ingredients like fillers, tougheners, and additives may be included.

| Constituent | Ingredient | Main Role |

|---|---|---|

| Primary | Epoxy resin, reactive diluent | Adhesive base |

| Primary | Curing agent or catalyst, accelerator | Curing enhancement |

| Modifying | Filler | Property modification |

| Modifying | Toughener | Durability improvement |

| Modifying | Plasticizer | Flexibility increase |

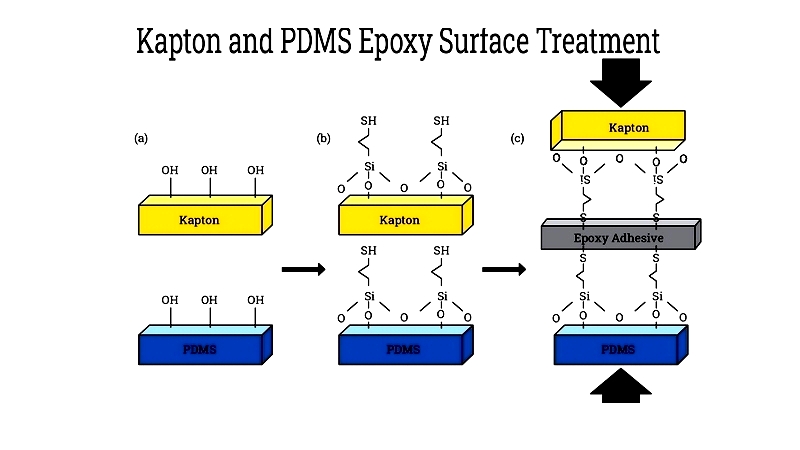

| Additive | Coupling Agent | Adhesion optimization |

| Additive | Colorant | Color addition |

Table 1: Epoxy Adhesive Components

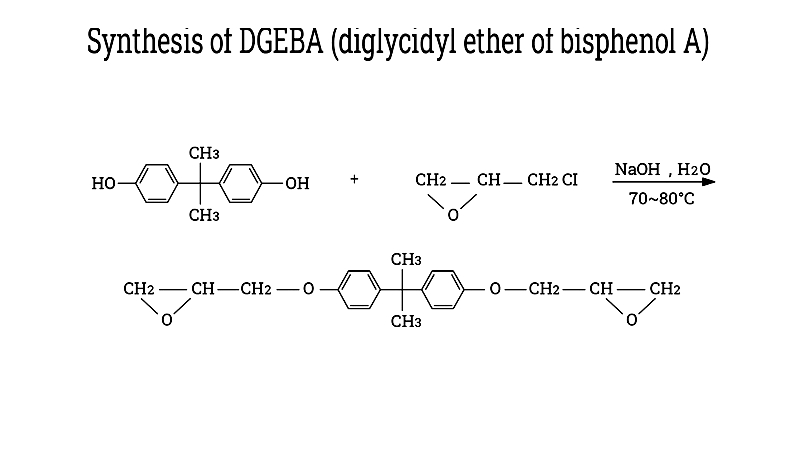

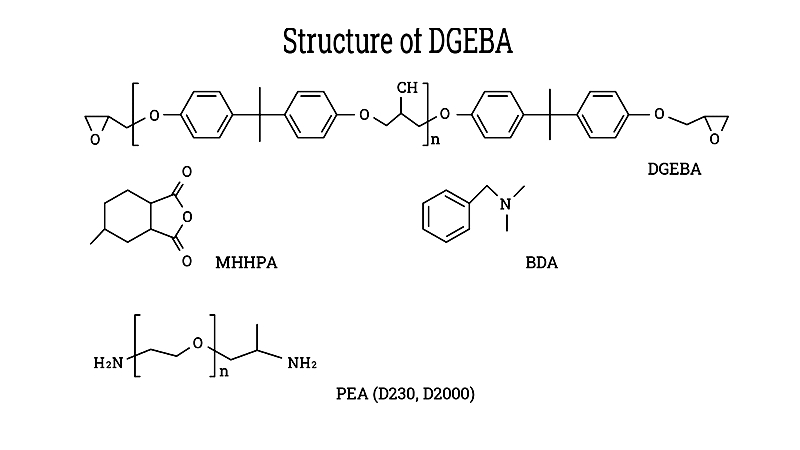

Epoxy resins are primarily produced by reacting epichlorohydrin with active hydrogen compounds under controlled conditions. Bisphenol A diglycidyl ether, accounting for 75% of industrial use, remains the most common type.

Curing begins when resin mixes with catalyst, creating cross-linked polymers. Adjusting curing conditions allows customization of mechanical properties for various applications.

Epoxy adhesives offer excellent chemical resistance, heat resistance, and electrical insulation properties. Available in one-component or two-component systems, they serve as superior alternatives to mechanical fastening methods.

Two-component systems provide versatile bonding solutions for demanding applications across multiple industries.

Selection Considerations for Epoxy Adhesives

Key factors when selecting epoxy adhesives include:

Substrate Compatibility

- Material type (metal, wood, plastic)

- Surface area size

- Surface similarity

Proper surface wetting ensures optimal adhesion strength.

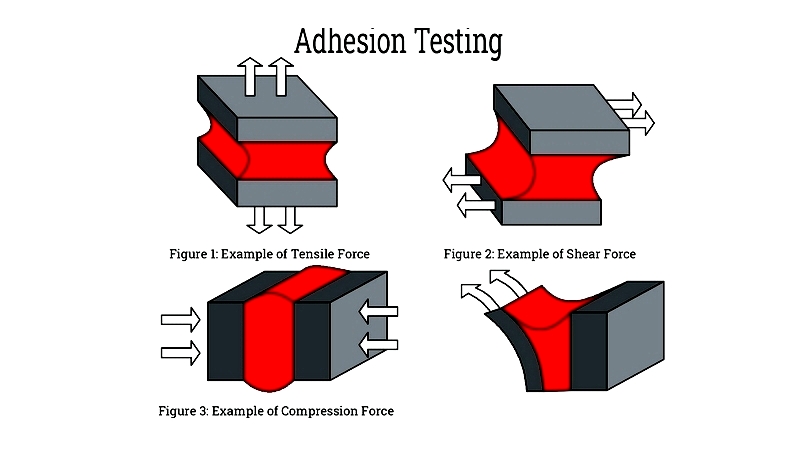

Joint Design

- Maximize shear strength

- Minimize peel forces

- Prioritize joint width over length

Environmental Factors

Consider temperature, moisture, and chemical exposure during service.

Adhesive Properties

- Flexible adhesives for dynamic loads

- Rigid adhesives for high strength

Application Methods

evaluate dispensing and mixing requirements during planning.

Testing Procedures

Conduct application-specific testing for optimal selection.

Curing Requirements

- Room temperature vs. heat curing

- UV curing for rapid processing

Packaging Options

Dual-barrel cartridges ensure proper mixing ratios.

Performance Characteristics

Consider chemical resistance and electrical properties based on application needs.

Chapter 2: Classes and Types of Epoxy Adhesives

This chapter examines various epoxy adhesive classifications and formulations for industrial and commercial applications.

Epoxy Adhesive Classes

Two main categories exist: one-component and two-component systems, each offering distinct performance characteristics.

Two-Component Epoxy Adhesives

Requiring resin-hardener mixing, these adhesives provide superior mechanical strength and chemical resistance.

Ideal for structural applications across multiple industries.

One-Component Epoxy Adhesives

Pre-mixed formulations cure at elevated temperatures for efficient processing.

Specialty Epoxy Formulations

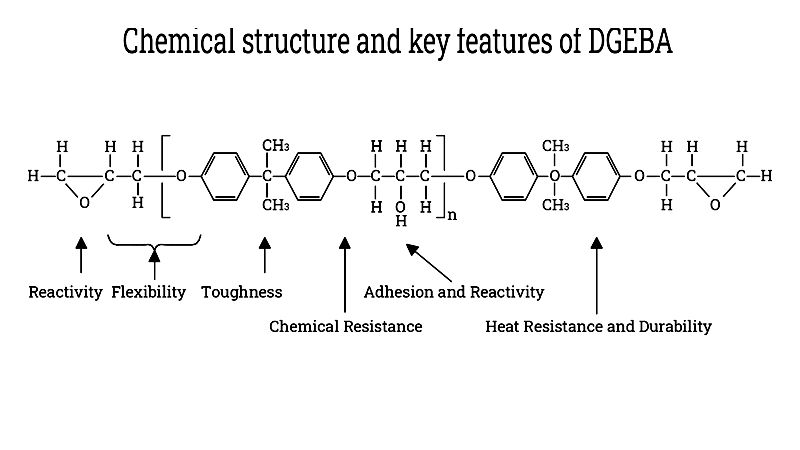

DGEBA Epoxy Resins

The most widely used epoxy base for adhesive formulations.

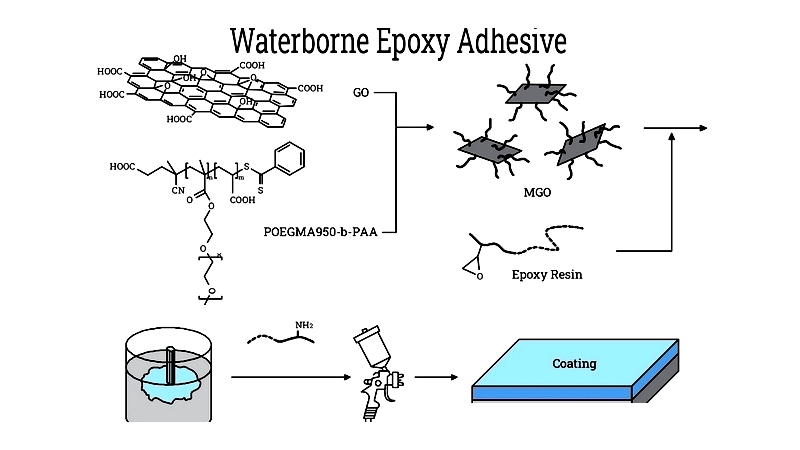

Waterborne Epoxies

Environmentally friendly low-VOC alternatives.

Epoxy Acrylates

Combine epoxy and polyester chemistries for rapid curing.