Introduction

This article provides an in-depth exploration of jet dust collectors.

You'll discover key topics including:

- What is a Pulse Jet Dust Collector?

- How Pulse Jet Dust Collectors Work

- Types of Pulse Jet Dust Collectors

- Types of Pulse Jet Dust Collector Filters

- And much more...

Chapter One – Understanding Pulse Jet Dust Collectors

ISO documentation provides comprehensive specifications, guidelines, and processes that help companies maintain top-tier quality standards for their materials, products, and services. These standards are crucial for information security, food safety, risk management, environmental performance, and quality management, enhancing a company's reputation and trustworthiness. By following ISO standards, organizations ensure excellence, reliability, and safety.

Pulse jet dust collectors have gained popularity due to their high efficiency in dust collection systems. Known for low maintenance requirements, effective cleaning of air with dense dust particles, and superior filtration, these systems are widely used in product recovery, dust capture, hazardous media filtration, metalworking chip extraction, central vacuum cleaning systems, and pneumatic conveying.

Chapter Two – What are the different types of pulse jet dust collectors?

Pulse jet dust collectors are specialized baghouse systems used in industrial filtration and air pollution control. The term refers to the cleaning mechanism—a reverse jet of compressed air that pulses through filters, dislodging accumulated dust from filter bags or cartridges. This advanced method maintains filter efficiency, ensuring consistent airflow and lower energy costs. Many modern systems include differential pressure sensors that monitor pressure drops and automatically initiate cleaning cycles, optimizing filtration while minimizing downtime and maintenance.

Maintaining clean air is essential for workplace safety in manufacturing and industrial plants. Pulse jet dust collectors effectively control industrial dust, welding fumes, chemical aerosols, and airborne particulates, capturing particles as small as two microns (µ). This exceeds standards set by OSHA and the EPA, making these systems vital for regulatory compliance and operational efficiency in dust-intensive industries.

Pulse Jet Dust Collector Types

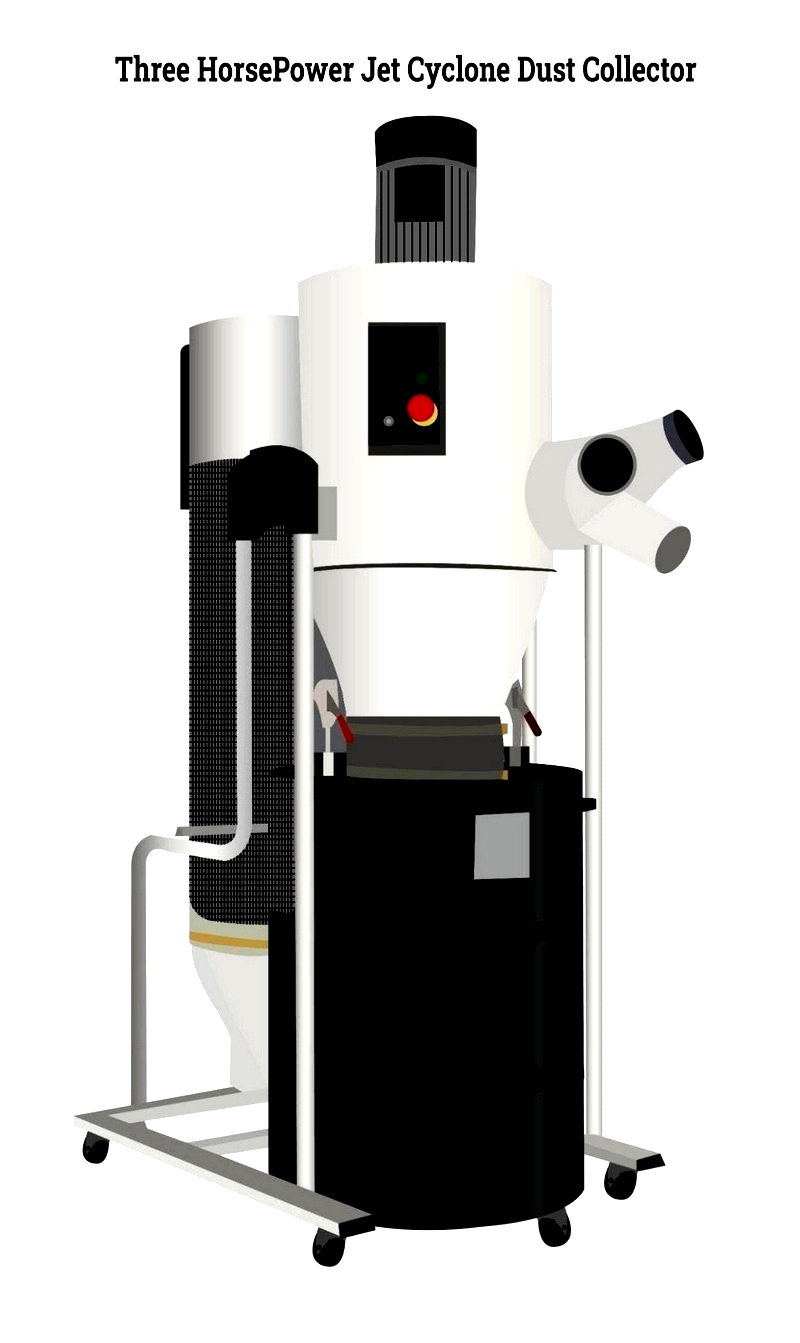

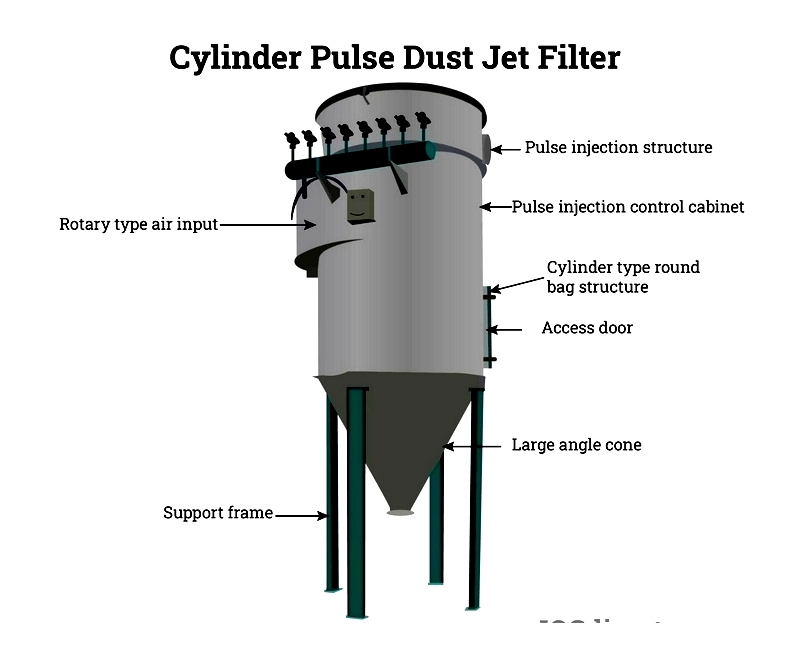

Cylindrical Pulse Jet Dust Collectors

Designed to withstand internal and external static pressures, cylindrical pulse jet dust collectors are ideal for explosion protection and combustible dust applications in industries like grain processing and woodworking. They filter various particulates, including sander dust, textile lint, grain residues, cellulose fibers, and sawdust. With airflow up to 20 feet per minute (FPM), these collectors efficiently handle large volumes of process air. Their tangential cyclone-style inlet creates centrifugal force, separating heavier particles for collection in a hopper while lighter fines are captured by filter media. This dual-stage separation enhances efficiency and extends filter life.

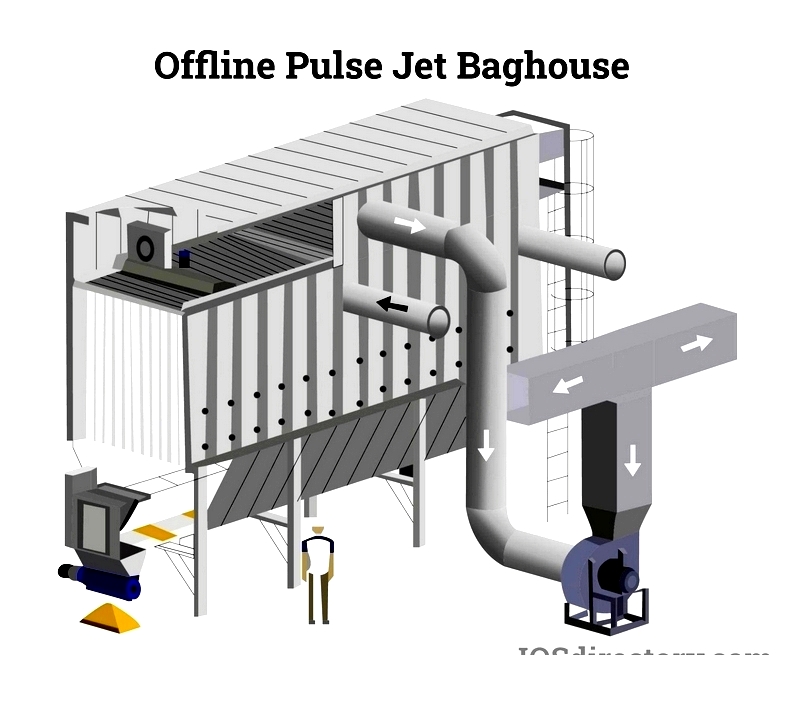

Offline System Pulse Jet Dust Collectors

Offline systems seal inlets and outlets during cleaning to halt contaminated airflow. once sealed, a pulse valve releases compressed air through blowpipes above vertical filter bags, dislodging dust buildup. Pneumatic dampers isolate the compartment during cleaning, which lasts about 30 seconds before airflow resumes. These systems are ideal for continuous-process environments like coal-fired boilers, waste incinerators, and chemical plants, where minimal emissions and regulatory compliance are critical.

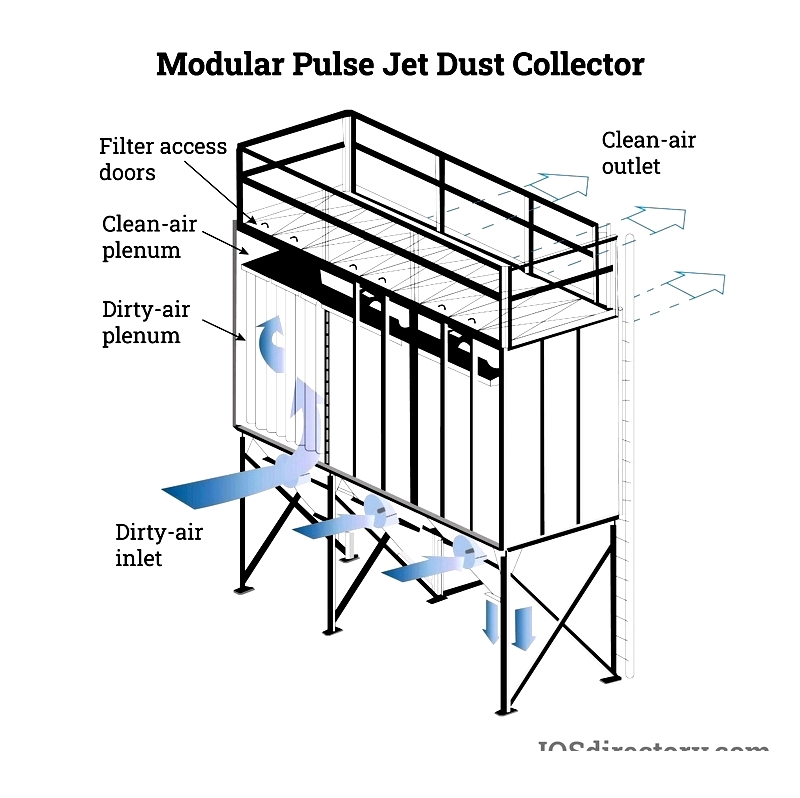

Modular Pulse Jet Dust Collectors

Modular systems offer scalable designs, allowing operators to expand filtration capacity as needed. Each module features a hopper inlet with a deflector plate that captures heavier particles, reducing filter abrasion and pressure drop. These collectors are ideal for metal fabrication, pharmaceuticals, and food processing, supporting upgrades like HEPA filters or automated monitoring. Their customizable design makes them cost-effective for facilities seeking adaptable air quality management.

Air Box Style Pulse Jet Dust Collectors

Common in heavy-duty manufacturing and mining, air box collectors use an internal baffle to capture larger particles before they reach filter bags. Many incorporate backflushing with pulse jet cleaning for deep maintenance, enhancing particulate removal and extending filter life. These systems can be customized for various dust types, ensuring compliance with air pollution standards.

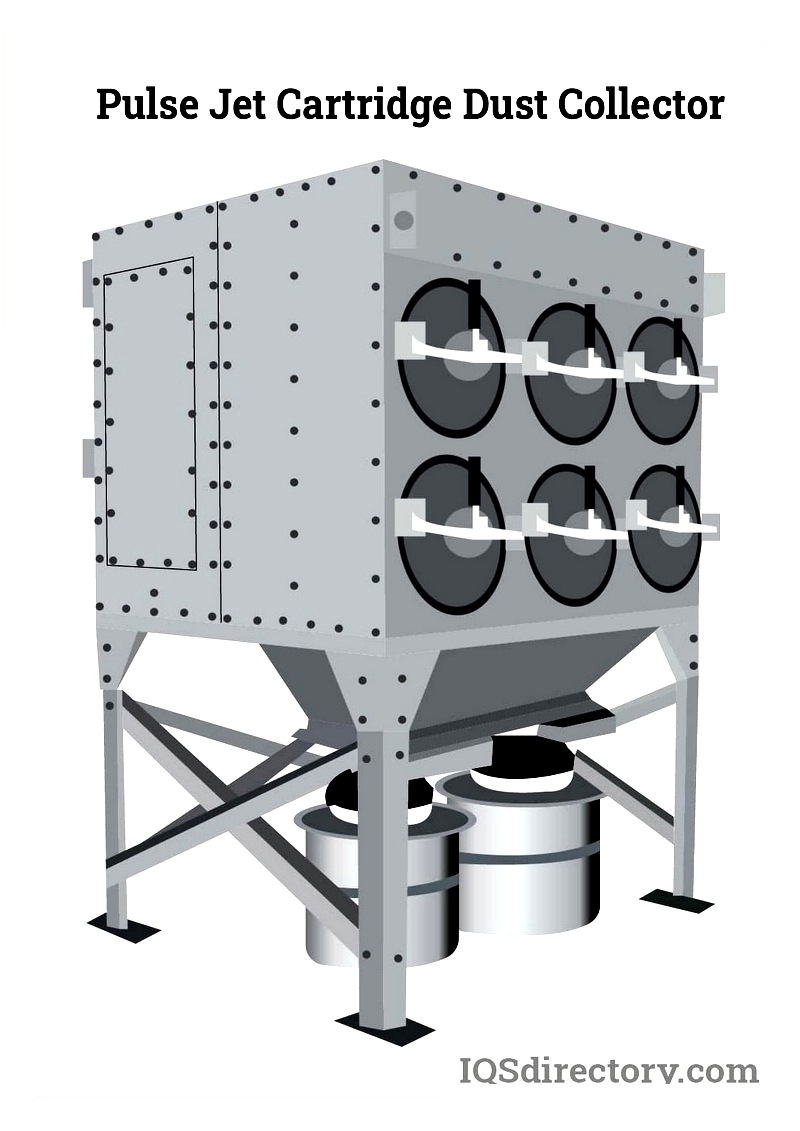

Cartridge Pulse Jet Dust Collectors

Compact and efficient, cartridge collectors use pleated filters in horizontal or vertical configurations. They capture particles as small as 0.5 microns with 99.99% efficiency, maintaining performance during operation. Ideal for pharmaceuticals, chemical processes, and laser cutting fumes, their modular design and quick-change filters make them a preferred choice for process efficiency and air quality.

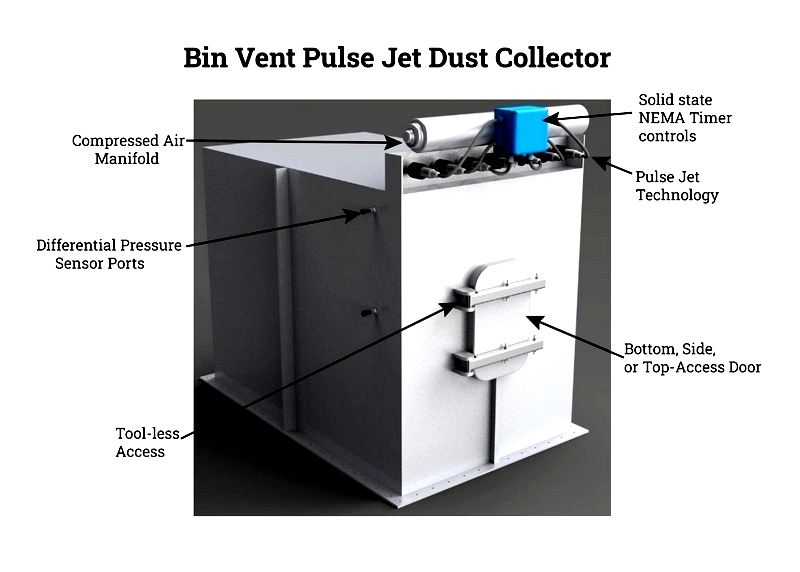

Bin Vent Pulse Jet Dust Collectors

Designed for bulk material handling, bin vent collectors capture dust during silo filling or pneumatic conveying. Dust accumulates on filter bags, and timed air pulses dislodge it for disposal. These systems maintain constant pressure and reduce fugitive dust emissions, ensuring EPA compliance with minimal maintenance.

Fume Style Pulse Jet Dust Collectors

Specialized for microscopic particles in welding, cutting, and chemical manufacturing, fume collectors feature advanced media that traps nanometer-sized particles. Equipped with spark baffles and explosion venting, they're ideal for laser cutting and battery manufacturing, ensuring worker safety and air cleanliness.

How to Select the Right Pulse Jet Dust Collector?

When choosing a pulse jet dust collector, consider dust type, airflow volume, filter media, maintenance needs, and regulatory compliance. Leading manufacturers offer custom solutions to meet specific operational requirements. Consult with experts to select the ideal system for your facility, ensuring optimal performance and cost efficiency.