Introduction

This article provides an in-depth exploration of labeling machinery.

Continue reading to discover more about:

- The fundamentals of labeling machinery

- Label printing machines

- Label applicators

- Print and apply labelers

- Labeling systems

- And much more...

Chapter 1: Overview of Labeling Machinery

Labels serve essential functions in product packaging, identification, presentation, and traceability. They enable manufacturers to communicate with consumers and provide crucial product information while enhancing brand recognition. Furthermore, labels facilitate item tracking throughout the supply chain. This section examines the different types of labeling machinery and systems available.

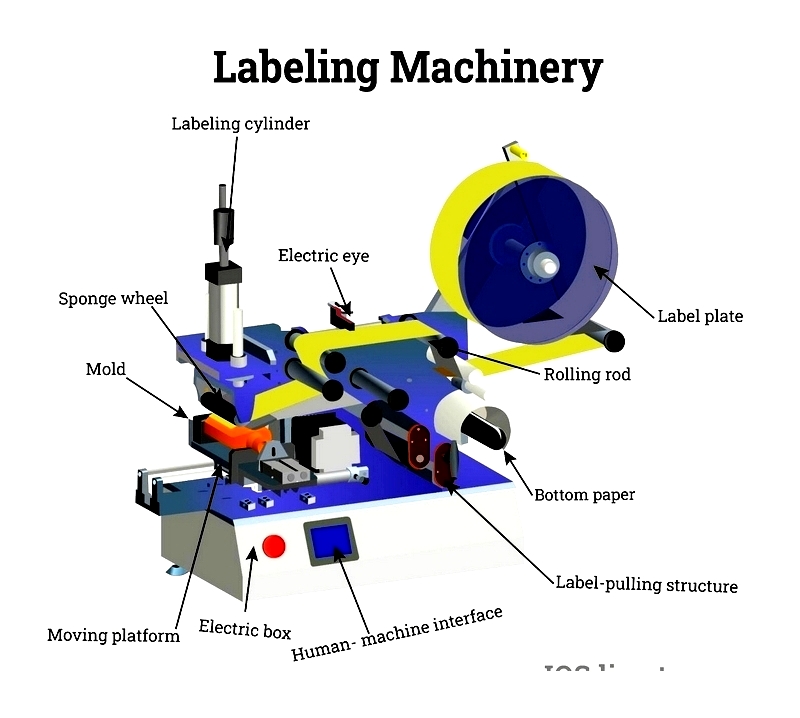

Labeling Machinery

Labeling machinery refers to specialized equipment designed for printing and applying labels to products.

These machines are indispensable across multiple industries, as nearly all commercial products require labeling on both items and packaging. They are also used for labeling cases, cartons, and pallets, serving sectors such as food and beverage, pharmaceuticals, agriculture, office supplies, and electronics. Highly versatile, these machines produce everything from basic barcodes and batch numbers to complex images and logos.

Labeling machines are typically classified by their specific functions in the labeling process, including printing, dispensing, and applying labels. Most systems integrate multiple functions into a single machine.

Labeling machinery operates at two automation levels:

- Semi-automatic labeling machinery requires operator involvement for certain steps. For example, the operator places the product on the labeling platform and initiates the applicator. The machine then automatically performs subsequent steps like label cutting and application. once labeled, the operator removes the product manually. This setup is cost-effective for small-scale operations but may have minor accuracy limitations.

- Automatic labeling machinery handles all labeling tasks with minimal human intervention. Typically configured inline with conveyor systems, these machines apply labels as products move along the production line. Ideal for large-scale operations, they ensure high precision and efficiency.

The following sections will explore various labeling equipment types and their specific applications.

Chapter 2: Label Printing Machines

The first step in product labeling is label printing. This process transfers designs onto materials like plastics, papers, vinyl, and metal foils using advanced printing technologies. After printing, labels are precisely cut and prepared for application, featuring adhesives that may be permanent, removable, pressure-sensitive, or heat-activated. Proper printing and adhesive systems are crucial for maintaining label durability and visual quality.

Various industrial label printing machines cater to diverse industry needs, including packaging, pharmaceuticals, and retail. Common printing technologies include:

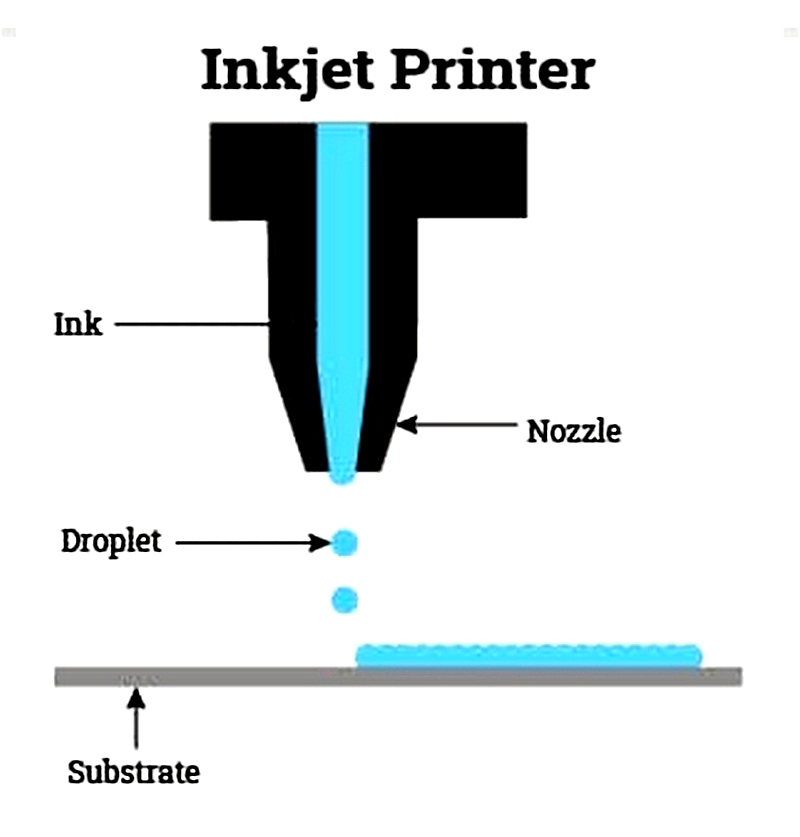

Inkjet Printers

Industrial inkjet printers use nozzles to deposit microscopic ink droplets, creating high-resolution images and text. They excel in variable data printing, such as barcodes and QR codes, and support materials like plastic films and coated papers. While affordable initially, ink costs can be higher for large-scale production.

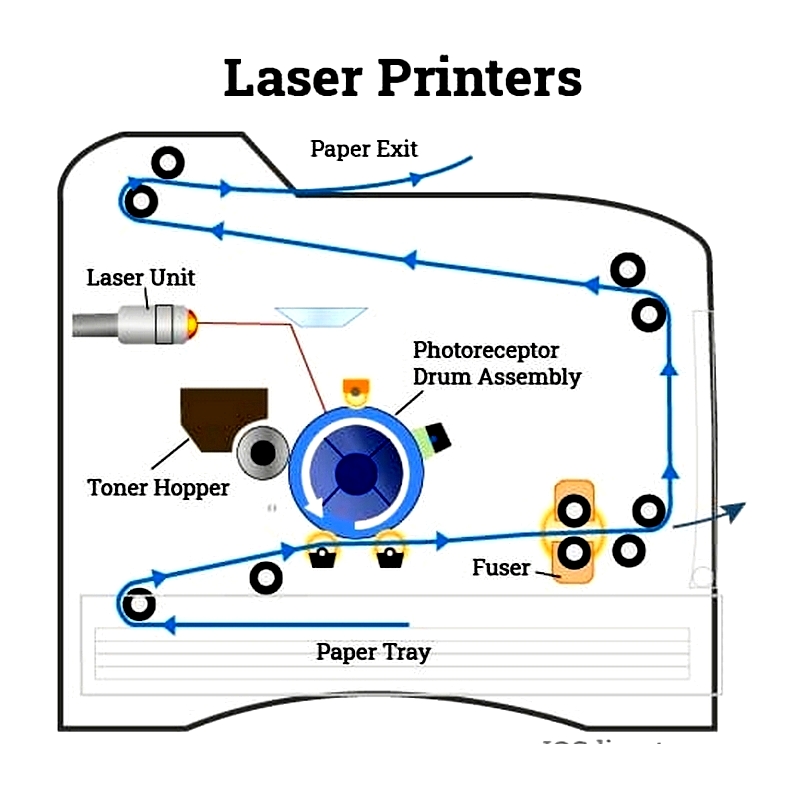

Laser Printers

Laser printers fuse powdered toner onto substrates using laser beams and heat. They produce durable, high-speed prints resistant to UV exposure and chemicals. Preferred for high-volume production, they offer consistent quality but support fewer materials than inkjet printers.

RFID Label Printers

RFID printers produce smart labels with embedded chips for data storage and transmission. They encode product information and print graphics simultaneously, essential for supply chain automation and inventory management. These printers support various frequency bands and are used in logistics, healthcare, and retail.

Thermal Printers

Thermal printers are cost-effective and efficient for label production, commonly used for shipping labels and barcodes. They come in two main types:

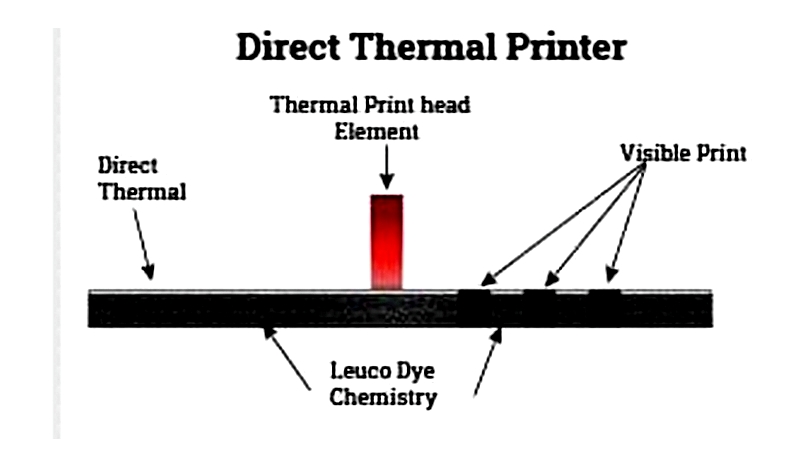

Direct Thermal Printer

Direct thermal printers use heat-sensitive materials that change color when heated, eliminating the need for ink or ribbons. Ideal for short-term labels, they are susceptible to fading under sunlight or heat.

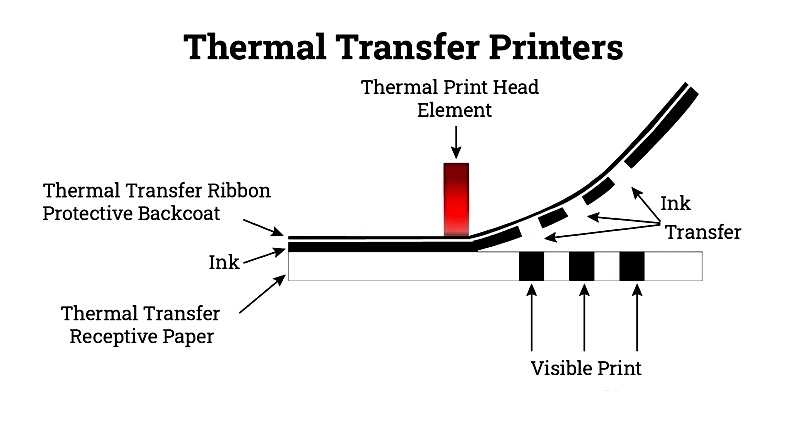

Thermal Transfer Printers

Thermal transfer printers melt ink from ribbons onto labels, creating durable prints resistant to UV, chemicals, and abrasion. They support various materials and are ideal for long-term applications like asset tags and compliance labeling.

Choosing the Right Label Printing Machine

Selecting the appropriate printer depends on factors like print speed, resolution, material compatibility, and durability requirements. Consider maintenance costs, consumables, and integration with existing systems. Consulting reputable manufacturers ensures access to tailored solutions for your industry needs, whether for short-run digital prints or high-volume industrial applications.