Introduction

This article provides an in-depth exploration of laser coolers and laser cooling technology.

Key topics covered include:

- Principles of Laser Cooling & Laser Coolers

- Laser Cooling Instruments and Chiller Types

- Applications of Laser Coolers & Laser Cooling

- And More...

Chapter 1: Principles of Laser Cooling and Laser Cooler Operation

This chapter examines the fundamentals of laser cooling, discusses various cooling techniques, and explains the working principles of laser coolers.

What is Laser Cooling?

Laser cooling refers to techniques that reduce atomic and molecular sample temperatures near absolute zero. These methods utilize photon re-emission momentum changes to decrease overall kinetic energy.

Thermodynamic temperature relates to particle velocity distribution - more uniform distributions indicate lower temperatures.

Laser cooling combines atomic spectroscopy with light's mechanical effects to narrow velocity distributions, thereby cooling particle groups.

Laser Cooling Methods

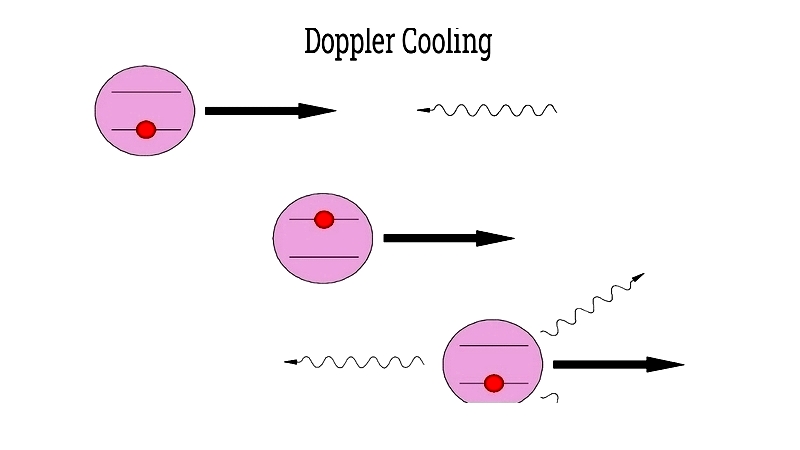

Doppler cooling is the most practical and widely used technique, often synonymous with laser cooling itself.

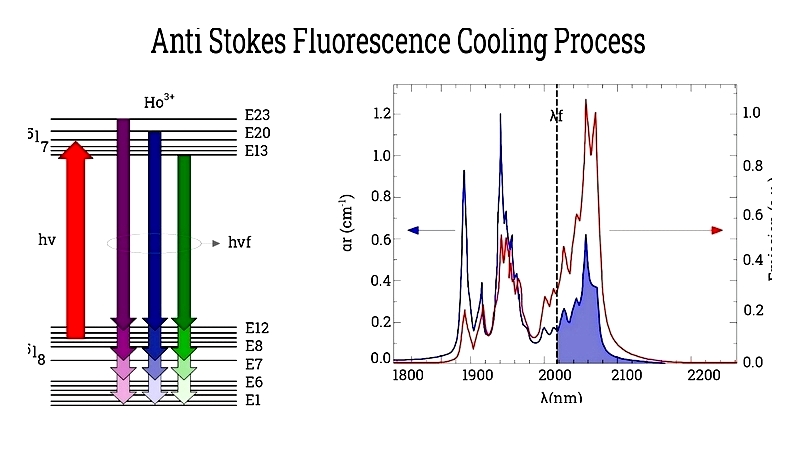

Other techniques include Sisyphus cooling, resolved sideband cooling, Raman sideband cooling, VSCPT, gray molasses, cavity-mediated cooling, polarization gradient cooling, anti-Stokes cooling in solids, EIT cooling, and Zeeman slower applications.

Doppler Cooling

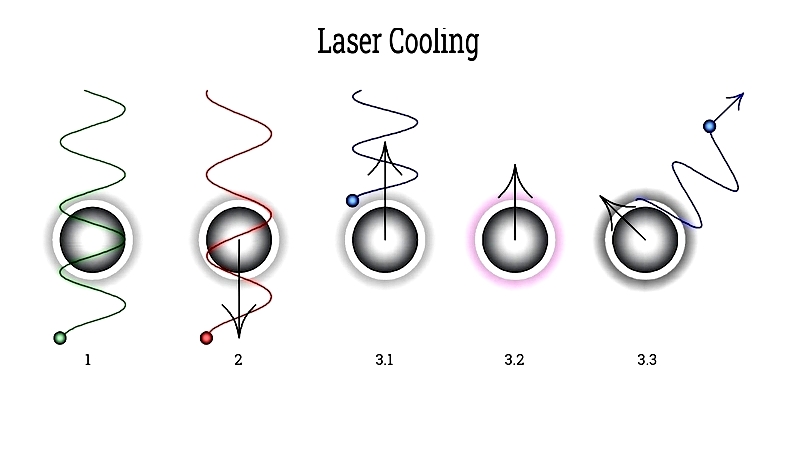

This method traps and reduces atomic motion to cool substances. Stationary atoms don't absorb photons, while moving atoms experience frequency shifts that enable selective absorption and deceleration.

When atoms absorb photons moving toward the laser, they slow down. Subsequent photon emissions in random directions create no net momentum change over multiple events.

The technique relies on atoms being transparent to most photon frequencies, interacting only at specific resonant bands. Carefully tuned laser frequencies below resonance allow selective interaction with moving atoms.

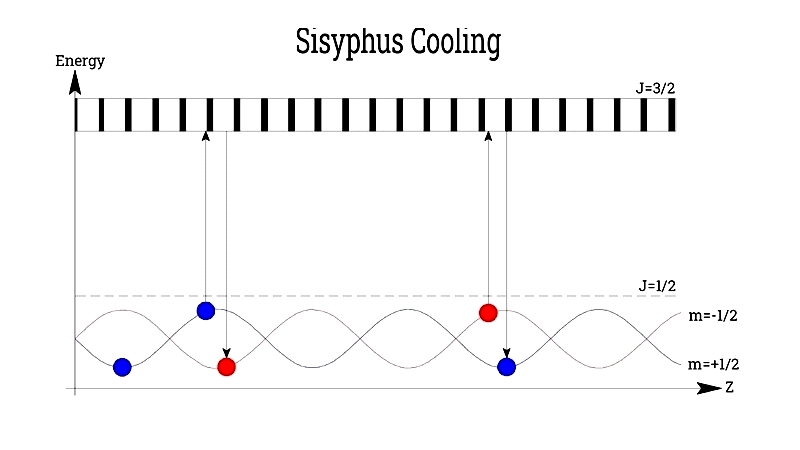

Sisyphus Cooling

This sub-Doppler technique uses counter-propagating orthogonally polarized lasers to create potential landscapes where atoms lose kinetic energy through optical pumping.

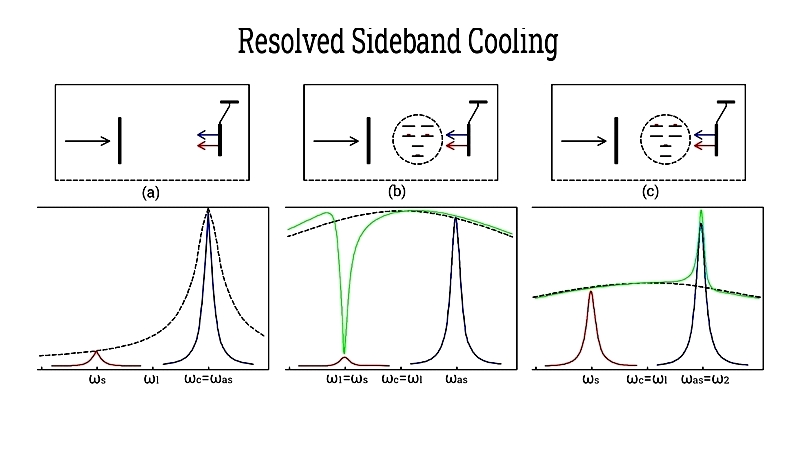

Resolved Sideband Cooling

This method cools tightly bound atoms beyond Doppler limits by aligning laser frequencies to red sidebands, enabling transitions to lower vibrational states.

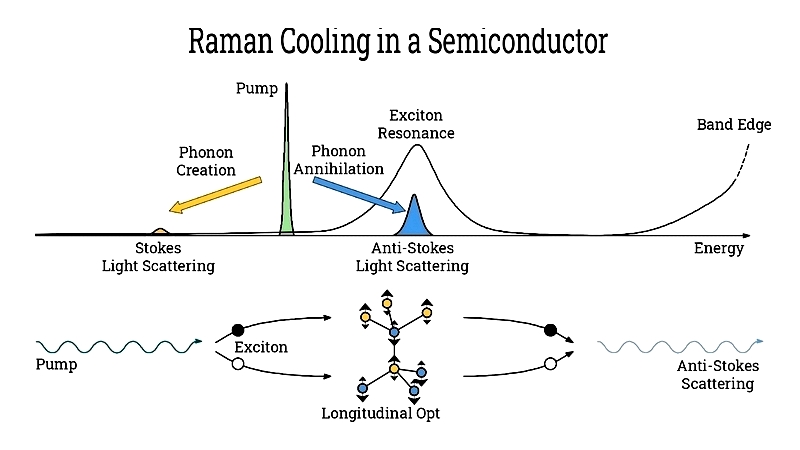

Raman Cooling

Raman cooling surpasses Doppler limits using optical molasses or optical lattices for precise atomic temperature control.

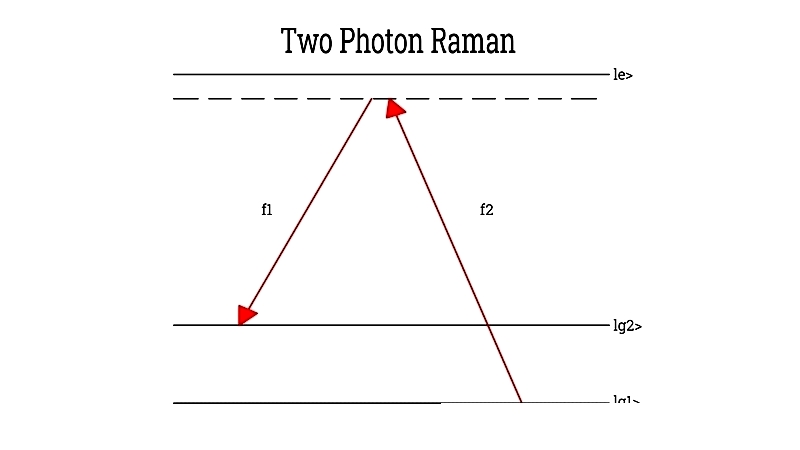

Two Photon Raman Process

Uses dual lasers to transition atoms between hyperfine states via virtual states.

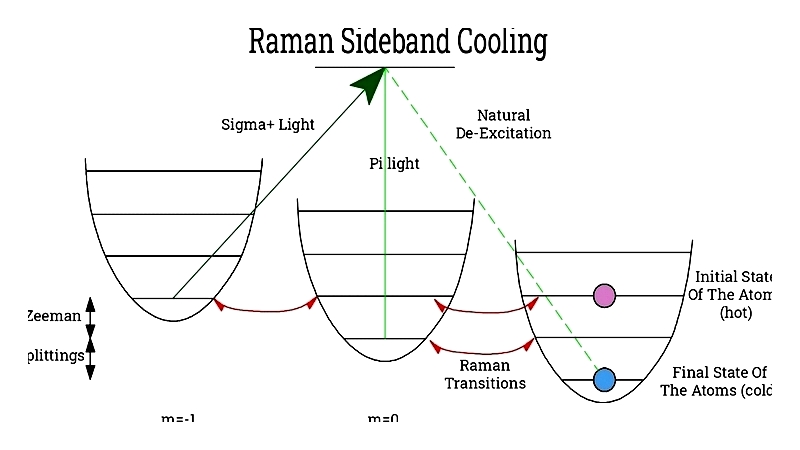

Raman Sideband Cooling

Begins with magneto-optical trapped atoms, transferring them to ground states through carefully controlled Raman processes.

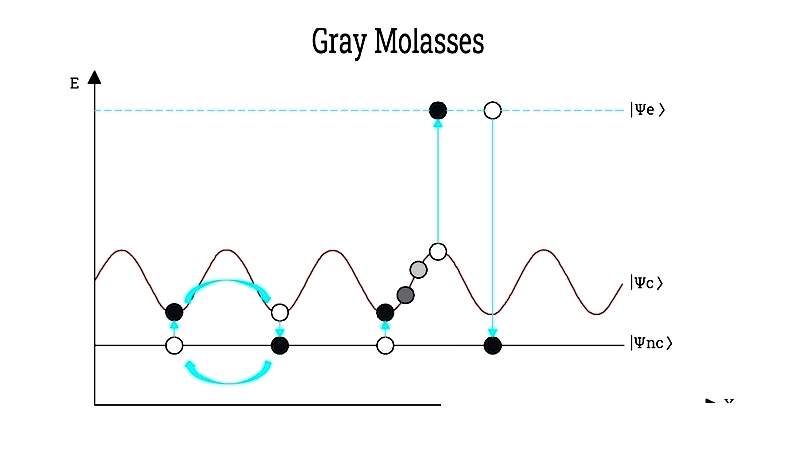

Gray Molasses

Combines Sisyphus cooling with dark states to achieve sub-Doppler temperatures for difficult-to-cool species.

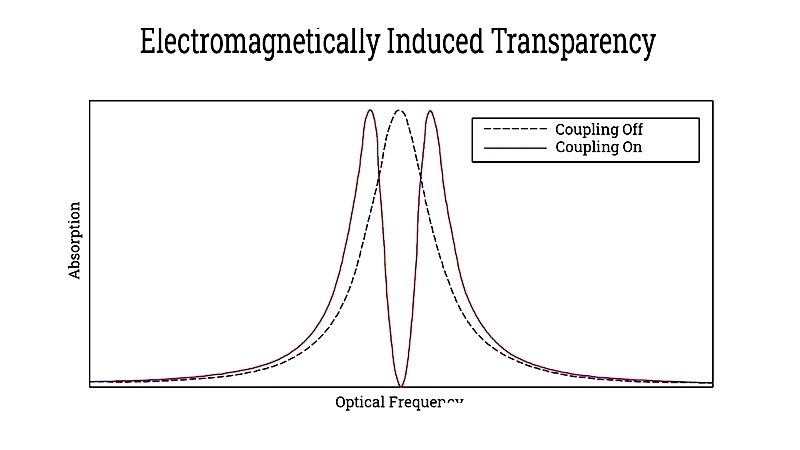

Electromagnetically Induced Transparency

Creates narrow transparent windows in opaque media using quantum interference between three atomic states.

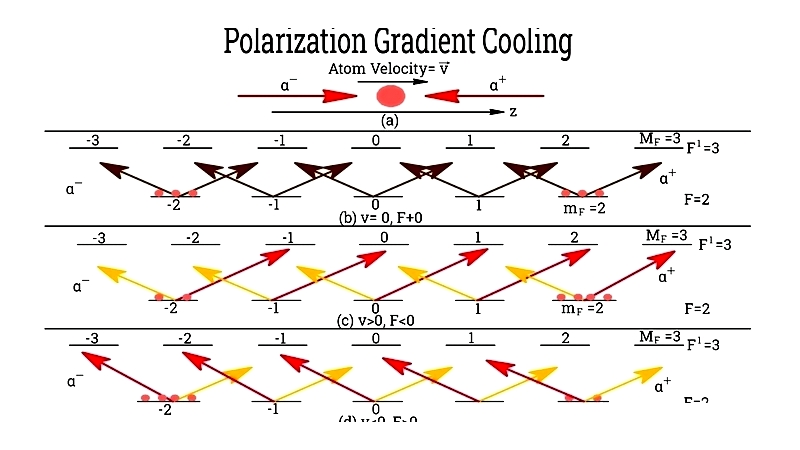

Polarization Gradient Cooling

Achieves ultra-low temperatures through spatially varying polarization states created by orthogonal laser beams.

Chapter 2: Laser Cooling Instruments and Chiller Types

This chapter examines common laser cooling devices and chiller types used for temperature control in laser systems.

Laser Cooling Instruments

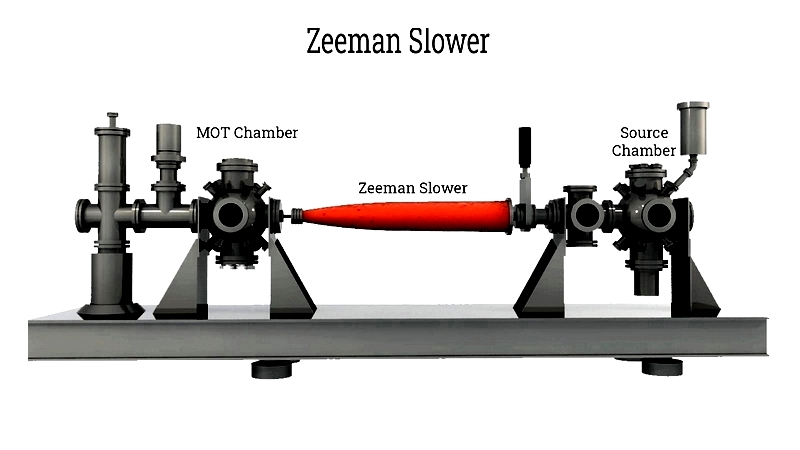

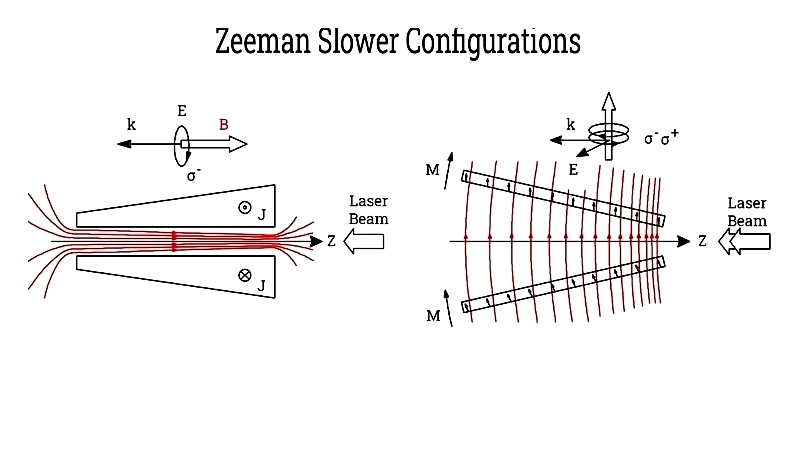

Zeeman Slower

Reduces atomic beam velocities from hundreds of m/s to a few Kelvin using Doppler cooling principles.

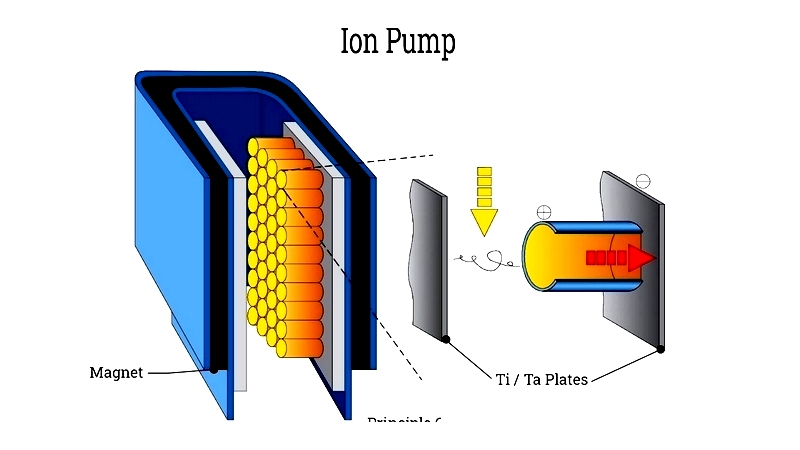

Ion Pump

Creates ultra-high vacuum environments (10-11 mbar) through sputtering for laser cooling experiments.

Laser Chiller Types

Centrifugal Chiller

Uses centrifugal compression for high-capacity cooling in industrial laser applications.

Laser Chiller System

Maintains precise temperature control for various laser types with advanced monitoring features.

Dimplex Thermal Solutions Drop-in Chiller

Dimplex Thermal Solutions Drop-in Chiller Thermal Care Dual Zone Chillers

Thermal Care Dual Zone Chillers