Introduction

This article provides an in-depth examination of quick disconnect couplings and their functions.

It covers detailed information on topics including:

- Couplings and Their Purpose

- Types of Quick Couplings

- Applications and Benefits

- And More...

Chapter 1: Understanding Couplings and Their Functions

This introductory chapter explores the concept of couplings and their importance across various industries.

Exploring Quick Disconnect Couplings

Quick disconnect couplings, also known as quick connect or quick release fittings, are designed for easy and rapid connection and disconnection of air and fluid lines. Unlike traditional fittings that require tools for assembly, these couplings provide a tool-free solution for diverse applications.

Couplings primarily serve to connect two rotating components while allowing for some flexibility or misalignment between them.

Roles and Applications of Couplings

Couplings play essential roles in machinery and systems, with their main function being power transmission between components. They also perform several other critical functions:

- Adjusting vibration characteristics of rotating assemblies

- linking driven and driving components

- Providing overload protection between rotating parts

- Reducing shock transmission between shafts

- Allowing slip during overload conditions

- Facilitating power transfer

- Absorbing shocks and vibrations

- Accommodating misalignment

- Blocking heat transfer

These functions will be explained in more detail below.

Power Transmission

Couplings mainly transmit power and torque between connected components or fluid lines.

Shock and Vibration Reduction

They help absorb shocks and minimize vibrations between components, reducing wear and extending equipment life.

Managing Misalignment

Misalignments may occur during initial setup or develop over time. Most couplings can handle angular, axial, or parallel misalignment.

Heat Transfer Prevention

Couplings can block heat flow between connected components, protecting machinery when the prime mover generates excess heat.

Types of Couplings

Couplings are broadly classified into rigid and flexible types, as described below.

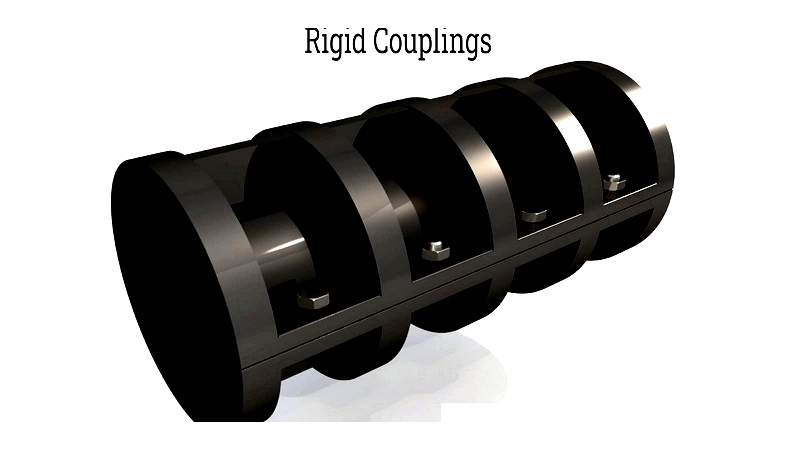

Rigid Couplings

Rigid couplings are used when components are perfectly aligned, with no tolerance for misalignment. They require precise alignment and are less versatile than flexible couplings.

Without misalignment compensation, rigid couplings are suitable for vertically aligned shafts, as misalignment can increase stress on bearings.

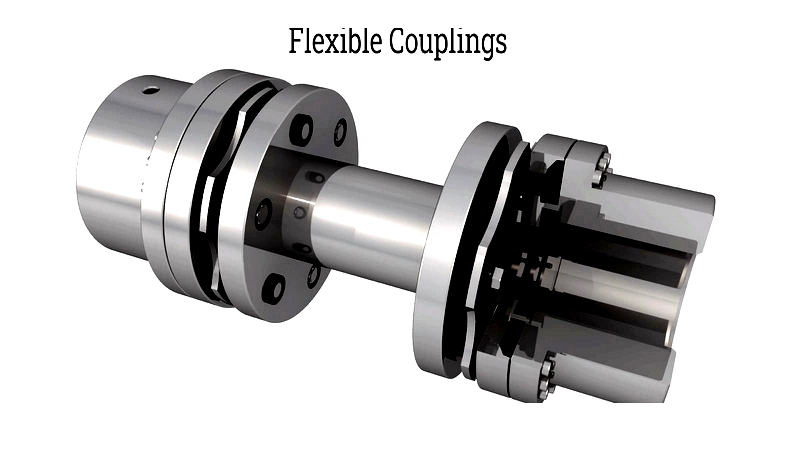

Flexible Couplings

Commonly used to transmit torque between a prime mover and rotating part, flexible couplings can tolerate some misalignment, though they shouldn't be solely relied upon for correction.

Flexible couplings handle temperature variations and axial movements while ensuring power transmission.

They are used in miniature applications (office equipment, precision tools) and industrial sectors (petrochemicals, heavy machinery).

Chapter 2: Different Types of Quick Couplings

This guide explores various fittings, quick-connect couplings, and quick-disconnect connectors used in fluid transfer systems. Understanding these solutions helps in selecting products optimized for specific needs.

Fittings

Fittings are installed at pipe ends to regulate flow, control pressure, change direction, or adjust diameter. They ensure reliable, leak-free performance in industrial and plumbing applications.

Types of Fittings

Common pipe fittings include:

Adaptor Fittings

These convert non-threaded pipes to threaded connections, essential for joining flexible tubing to threaded systems.

Caps

Pipe end caps seal pipe ends, preventing leakage in hydraulic and pneumatic systems.

Copper Tubing Fittings

Used with copper piping, these fittings include couplings, tees, and reducers for water and refrigerant systems.

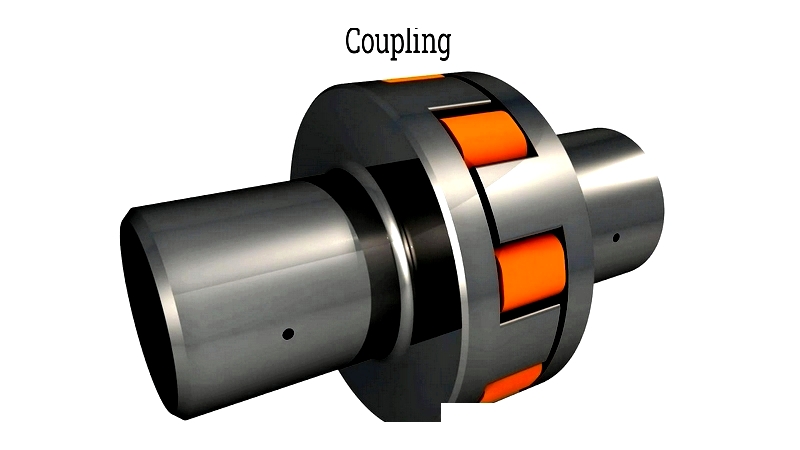

Couplings

Couplings connect straight pipe sections, available in various materials for different applications.

Elbows

Elbow fittings change flow direction, typically at 45° or 90° angles.

Hex Bushings

These reduce pipe size abruptly, useful in compressed air and water systems.

Nipples

Short threaded pipe sections for connecting fittings or extending pipelines.

Plugs

Plugs seal threaded fittings for maintenance or temporary blockage.

PVC Fittings

Lightweight, corrosion-resistant fittings for irrigation and wastewater systems.

Reducers

Allow transition between different pipe diameters.

Street Elbows

Compact elbows with male and female threads for tight spaces.

Tee Fittings

Form T-shaped intersections for branch lines, used in various industries.

Unions

Enable easy pipe connection/disconnection without rotation.

Valves

Control fluid flow, available in multiple types for different applications.

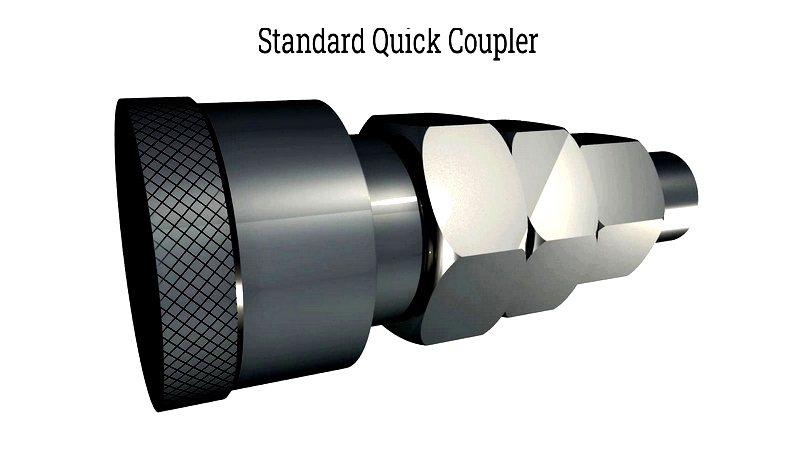

Quick Connect Couplings

These enable rapid, tool-free connection of fluid or air lines, minimizing leakage during maintenance.

They feature automatic shut-off valves and are available in various materials for different fluids.

Types of Quick Connect Couplings

Common types include:

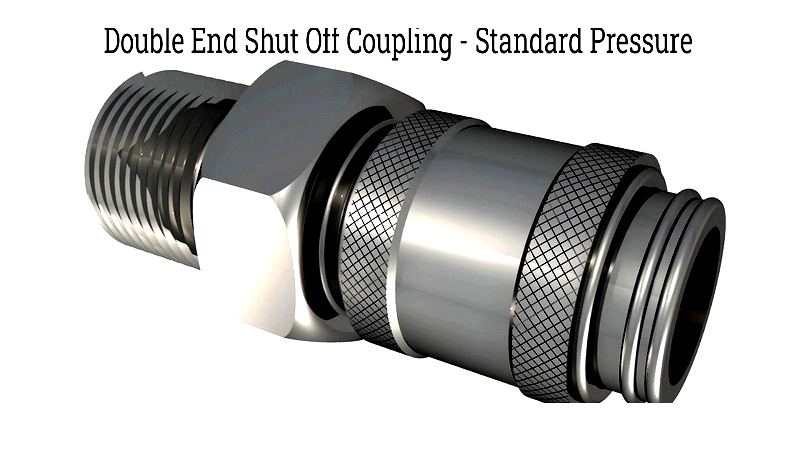

- High Pressure Double End Shut Off: For water and hydraulic systems up to 215 bar.

- Standard Pressure Double End Shut Off: For general industrial use up to 100 bar.

- Ultra High Pressure Double End Shut Off: For heavy-duty applications up to 2500 bar.

- Line Couplings: Connect multiple lines simultaneously.

- Single End Shut Off: For low-pressure applications up to 20 bar.

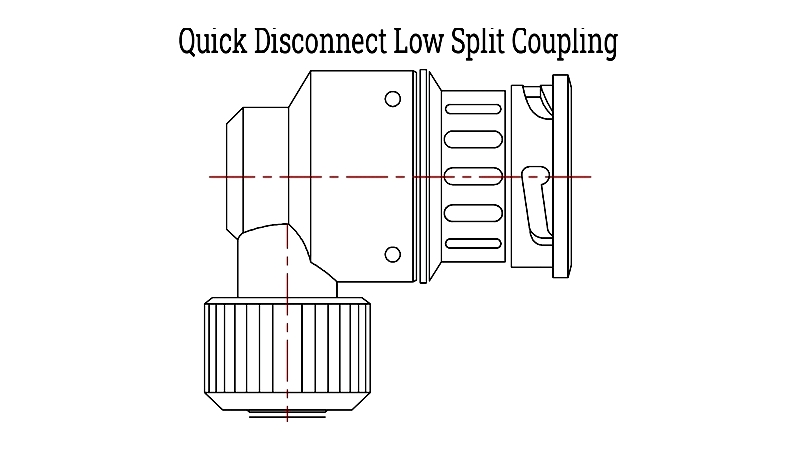

Quick Disconnect Fittings

These allow fast, tool-less connection of fluid lines, improving efficiency and safety.

Available in various styles for different pressure ratings and applications.

Types of Quick Disconnects

Popular types include:

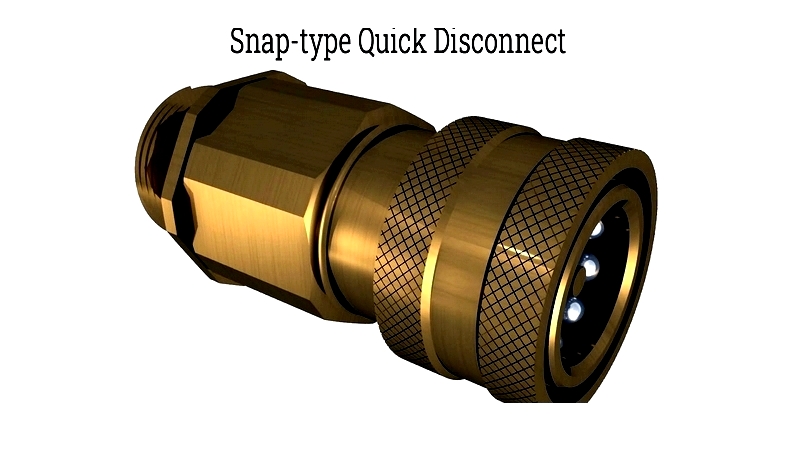

Snap-type Quick Disconnect

Feature spring-loaded ball latches for quick engagement, ideal for frequent changes.