Introduction

This article provides an in-depth exploration of perforated aluminum.

After reviewing the following information, you'll gain deeper insights into:

- What perforated aluminum is

- How aluminum perforations are made

- Key considerations for perforating aluminum

- Different aluminum perforation patterns

- Various aluminum alloy types

- Factors to consider when perforating different aluminum grades

- Benefits and drawbacks of perforated aluminum

- Applications of perforated aluminum

- And much more...

Chapter 1: Understanding Perforated Aluminum: Creation and Applications

Perforated aluminum is created by punching or piercing aluminum sheets using either manual techniques or advanced CNC technology. This process allows for the production of diverse shapes and patterns to meet specific requirements. Today, perforated metal panels are widely used in architectural applications, serving as acoustic panels, decorative lighting elements, signage, and industrial filtration solutions. The evolution from traditional hand techniques to modern machinery has enabled more precise patterns and sizes based on material type, panel dimensions, and client needs. Aluminum is one of the lightest commercially available metals, with a density about one-third that of steel or copper. Its exceptional strength-to-weight ratio makes it particularly valuable in automotive and transportation sectors, contributing to increased payloads and improved fuel efficiency. However, pure aluminum has limited tensile strength, which is enhanced by alloying with elements like manganese, silicon, copper, and magnesium to create materials with improved properties for various applications. When exposed to air, aluminum quickly forms a protective oxide layer that provides excellent corrosion resistance, though it's less resistant to alkaline substances like lime or soda.

Why Choose Perforated Aluminum

Aluminum's lightweight, strength, and flexibility make it easy to install. Like stainless steel, it offers visual appeal, making it suitable for applications requiring sound and light diffusion.

- Perforated aluminum sheet metal is lighter than solid versions due to its hollow structure, allowing significant reduction in building loads without compromising structural integrity. The superior strength-to-weight ratio enables more economical and compact construction.

- Aluminum naturally resists corrosion through its protective oxide layer. When exposed to oxidizing environments, this thin coating forms automatically. Additional surface treatments like painting or anodizing can further enhance corrosion resistance.

Creating Aluminum Perforations

The perforation process begins with flat aluminum sheets that can be cut and shaped despite their thinness. In North America, sheet metal thickness is measured in gauges, while millimeters are used elsewhere. The perforation design depends on intended function, with variations available in style, size, and hole orientation. Key factors affecting performance include required strength, specific application, and hole design. When designing perforated aluminum, considerations include hole size and bar width (the material between holes). The material's strength depends on balancing these elements - larger holes with narrower bars reduce strength as material density decreases. For effective perforation while maintaining structural integrity, aluminum thickness should generally not exceed hole diameter or bar width.

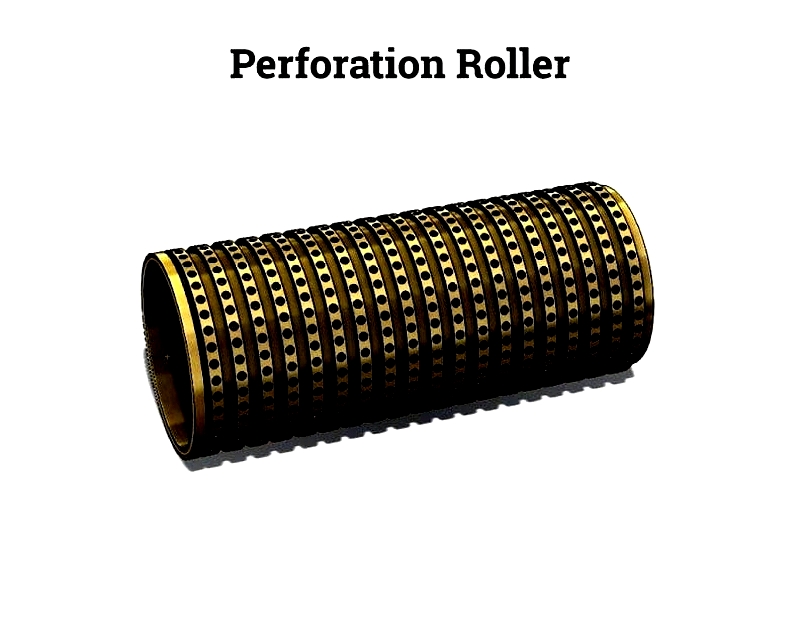

The rotary-pinned perforation roller is the most common method, though other techniques are also available.

Roller Perforation for Aluminum

A rotary-pinned perforation roller features a large cylinder with protruding needles that puncture holes in metal. As the sheet passes over the rotating roller, the needles create consistent perforations. Sometimes heated needles are used to melt the metal, forming reinforced rings around each hole and allowing various hole sizes.

Laser Perforation

Laser beams use compressed gas to melt and vaporize aluminum until holes form. By moving the beam consistently, cutting patterns emerge. Thermal cutting typically requires pre-drilling a small hole before laser cutting. The process involves directing a laser beam onto the metal plate where energy absorption and melting occur without reflection, accelerating as the molten pool deepens.

Laser perforation falls into two categories:

- Blasting Perforation: A continuous high-energy laser beam melts the target, with auxiliary gas forming holes. While fast, this method may lack precision due to continuous irradiation. Adjusting the laser focus above the material surface widens the aperture for rapid heating, reducing perforation time despite potential spatter.

- Pulse Perforation: Uses pulsed lasers with high peak power to irradiate the plate, causing minor melting. The process repeats to create patterns, leaving minimal heat and residue due to intermittent laser application.

Nibbling Machine Technique

This process uses a punch to make successive cuts in metal sheets. Electro-hydraulic powered nibbling machines precisely punch, cut, and form materials, handling tasks like punching, slot cutting, and rectangle pattern creation.

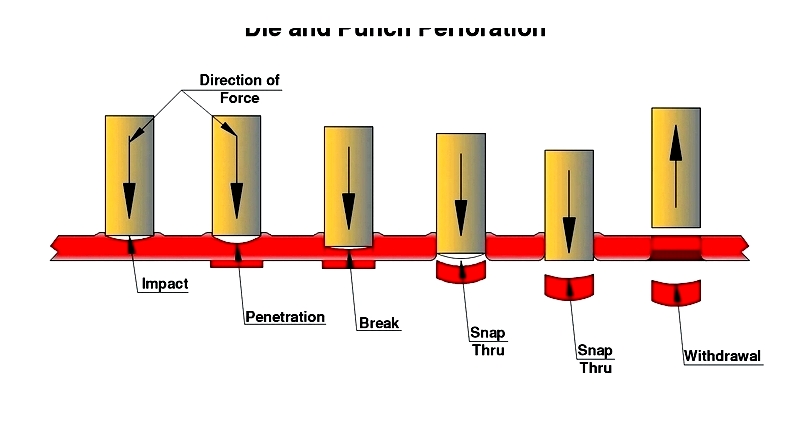

Punch and Die Method

This straightforward technique positions material over a die matching the punch's size and pattern above. The descending punch aligns with the die to create holes, with chips removed by vacuum. This method efficiently perforates metal screens and panels over large surfaces.

All-Across Perforating Press

This press can perform up to 1,600 punches per stroke, offering high efficiency and precision. Suitable for materials 0.002-0.25 inches thick and over 60 inches wide, it achieves thousands of holes per minute at up to 600 strokes per second.

Plasma Perforation

Plasma cutting uses an electrical arc to ionize gases, creating cutting plasma. The circuit includes a tungsten electrode and the aluminum sheet. The torch's grounding clamp creates an arc, with ionized plasma heating to extreme temperatures to cut metal.

Higher temperatures increase plasma speed. At optimal temperature, plasma cuts aluminum, removing molten metal and oxides cleanly. Various gases like hydrogen, nitrogen, or argon-hydrogen mixtures can be used, with the latter preferred for aluminum perforation.

Chapter 2: Leading Aluminum Perforating Machines

The U.S. and Canada offer specialized machinery for precise aluminum perforation. These machines enable high-speed, cost-effective production of perforated sheets, panels, and coils sought in architectural, automotive, and construction industries for their lightweight, corrosion-resistant, and versatile properties. Understanding available equipment helps manufacturers select optimal solutions for production needs. Below we examine advanced aluminum perforating machines, highlighting their features, versatility, and advantages.

Metl-Span Perforator

Manufacturer: Metl-Span

Renowned for precision, this machine handles various aluminum thicknesses and creates diverse hole patterns for architectural and acoustic applications. Its advanced punch tooling enables rapid changeovers with minimal waste, ideal for wall cladding, ceilings, and building components.

Cidan Machinery's Pro Z Series

Manufacturer: Cidan Machinery

Popular models like Pro Z21 and Z30 feature robust construction and user-friendly interfaces. Their programmable hole patterns and automatic tool changers allow rapid, accurate perforation for ventilation grilles and facade panels