Introduction

This article provides an in-depth exploration of 5-axis CNC machining.

Key topics covered include:

- Principles of 5-Axis CNC Machining

- Types of 5-Axis CNC Machining

- Applications and Benefits of 5-Axis CNC Machining

- And More...

Chapter 1: Understanding the Principle of 5-Axis CNC Machining

This section examines the fundamentals of 5-axis CNC machining, including its structure, mechanics, and functionality.

Defining 5-Axis CNC Machining

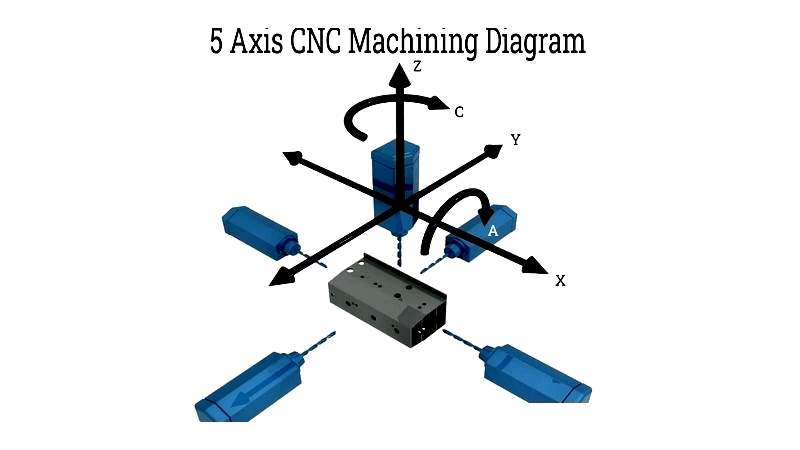

While standard CNC machines operate along three primary axes (X, Y, and Z), 5-axis CNC machines incorporate two additional axes (A and B). These extra dimensions enable the production of more complex and precise parts. This technology has gained popularity due to its ability to significantly reduce manufacturing time.

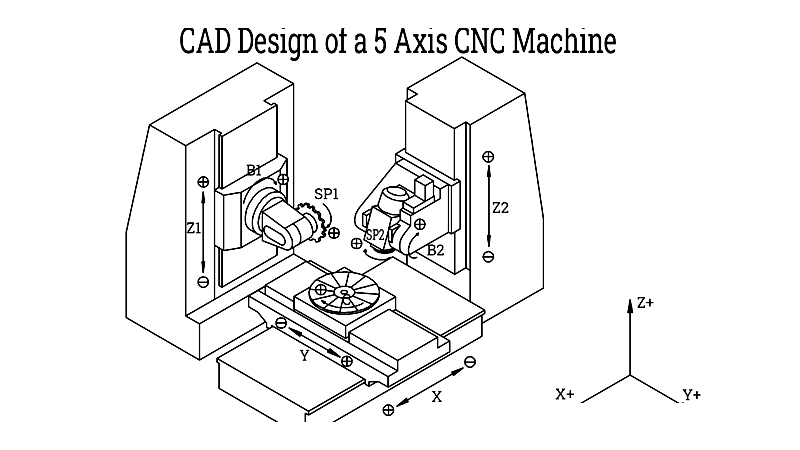

The rotating cutting tools in CNC systems precisely shape desired geometries. By using a table that moves and rotates across all five axes, stress on cutting tools is reduced, extending the machine's operational life. Below is an illustration of a 5-axis CNC machine.

The Concept of CNC Machining

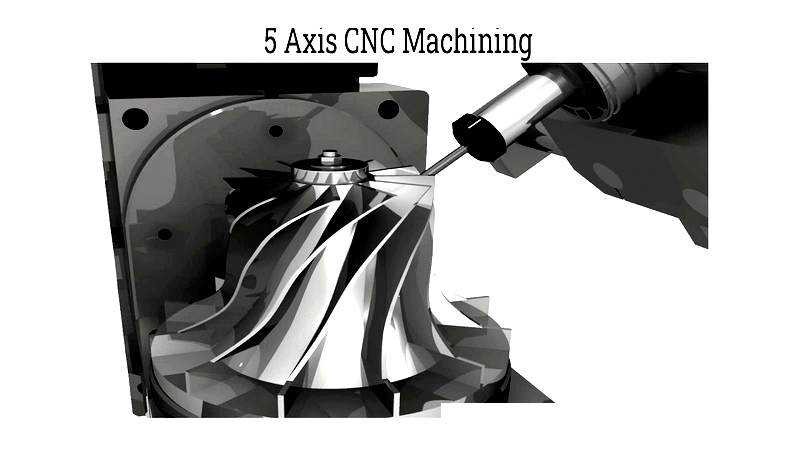

5-axis machining represents an advanced evolution from standard 3-axis CNC methods. This computer-controlled mechanical process moves tools across five directions with high accuracy to efficiently remove material and create parts. The process begins with a CAD design, which is converted into precise CNC codes that guide machine operations.

CNC machining delivers high-quality results for applications requiring both horizontal and vertical setups, including intricate turned parts.

The versatility of CNC machines allows for efficient production of components in a single operation, including collars, bushings, fittings, fasteners, and spindles.

Constructing 5-Axis CNC Machines

A 5-axis CNC machine consists of several essential components:

Kinematic Analysis

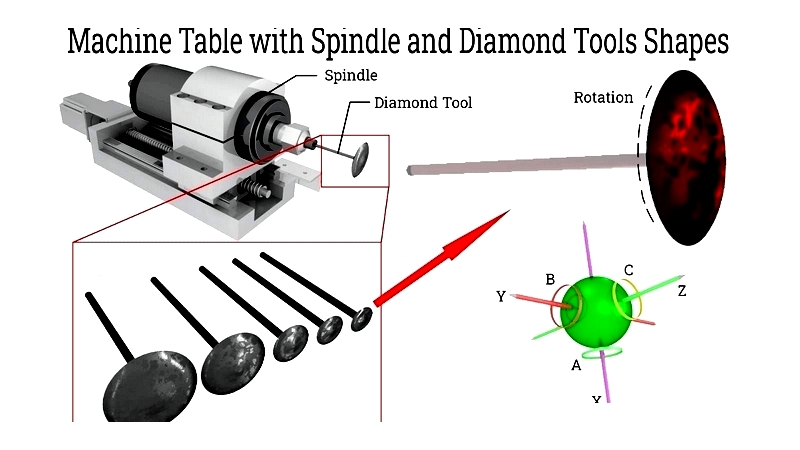

Diamond tools are typically used for precision applications, featuring cutting surfaces coated with diamond particles. Figure 1.3 shows a machine table with a spindle for gemstone cutting, illustrating the diamond tool's motion directions. These tools, designed for precise edges, incorporate diamond particles across their surfaces.

Tool size selection depends on the cut width and desired surface finish. The diameter of the diamond particles matches the tool head's diameter. The tool primarily operates along the Z, X, and Y axes, while the B and A axes enable precise carving of curved patterns on workpieces.

For brittle materials like sapphire and marble, processed sizes typically do not exceed 60x60x60 mm³. Due to their hardness, abrasive machining is used, with diamond tools operating at 8,000 to 12,000 RPM. The tool's unique shape requires horizontal orientation, aligning with the rotation plane. Key design parameters are listed below.

Key Components of a 5-Axis CNC Machine

Established design principles guide the selection of core components and systems. The initial design phase involves choosing primary parts and innovating new systems for specific needs. Main components include:

- Step motors (X, Y, Z)

- Step motors (A, B)

- Spindle motor

- Stepper motor driver

- Linear motion – ball screws

- Timing belts

- Controller

Machine Design Strategy

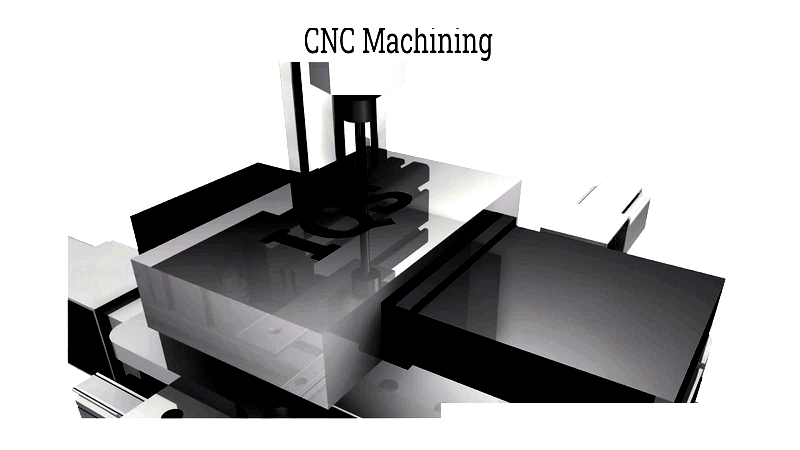

CNC machine design encompasses both electrical and mechanical frameworks. Mechanically, parts must be assembled for stability and efficient energy transfer. The supporting frame ensures precise, flexible movement between components.

Axis movements and spindles are aligned for optimal functionality. Mechanical parts are designed, evaluated, and simulated using Inventor software. A 3D CAD model of CNC machinery is shown above. Stepper motors drive the Z, X, and Y axes via ball screws, while timing belts drive the B and A axes. Commercially available parts are integrated with custom components for specific functions. B and A axis calibration ensures solid connections, achieved with durable materials. Key steps include using timing belts to reduce motor torque and determining dimensions and ratios. Complete assembly and adjustments are performed through 3D CAD simulations.

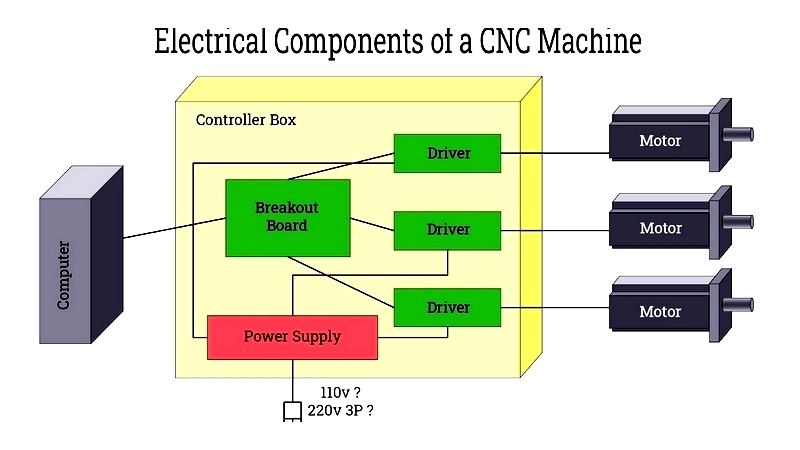

The electrical system supports machine operation, using a DC power setup with variable voltages: 5VDC for control inputs, 24VDC for motors, and 12 to 100VDC for spindle speed regulation. The electrical schematic is shown in Figure 1.5 below.

Functionality of 5-Axis CNC Machining

CNC machining uses subtractive technology to shape parts by removing material until the desired form is achieved. The process starts with a CAD file, converted into G-Code for the CNC system.

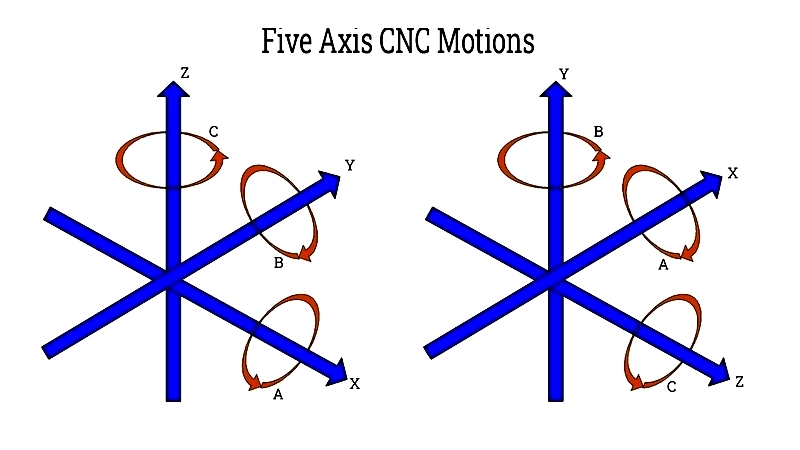

Unlike standard 3-axis CNC milling machines, 5-axis machines use additional axes for cutting from multiple angles, accommodating complex designs. The 5-axis system introduces A, B, and C axes for enhanced flexibility.

A 5-axis CNC cutter approaches the workpiece from five angles. It moves along Z, X, and Y axes while rotating across A, B, or C axes. The axes and their movements are:

- X axis – Left to right

- Y axis – Front to back

- Z axis – Up and down

- A axis – 180-degree rotation around X axis

- B axis – 180-degree rotation around Y axis

- C axis – 180-degree rotation around Z axis

5-axis cutting tools rotate to create intricate designs with superior finishes. Axes A, B, and C rotate freely around Z, X, and Y. The CAD model or machine configuration determines which