Introduction

This article provides an in-depth examination of car wash equipment.

You'll explore various topics including:

- What is Car Wash Equipment?

- Types of Car Wash Equipment

- Car Washing Methods

- Types of Car Wash Systems

- And Much More...

Chapter One – What is Car Wash Equipment?

Car wash equipment consists of various components designed to work independently and collectively within a system to accomplish specific cleaning objectives. Each element contributes uniquely to enhance the overall cleaning process. The equipment is carefully engineered to handle vehicles of different sizes, incorporating water, reclamation units, detergents, sprayers, brushes, and cleaning cloths into the washing process.

The primary goal of car wash equipment is to provide a smooth and efficient cleaning experience as vehicles progress through each wash stage. To ensure customer satisfaction, operators must carefully plan their setup, choosing equipment that meets both customer expectations and local regulations. Manufacturers offer guidance to help select optimal equipment that balances budget constraints with business requirements.

Chapter Two – Types of Car Wash Equipment

Car wash equipment varies by manufacturer, system type, and cleaning method. From automatic and touchless systems to tunnel and self-service options, each category features specialized components and technologies to deliver superior cleaning results. Modern equipment prioritizes efficiency, durability, and vehicle protection—factors that impact operating costs, water consumption, and customer satisfaction. The extensive selection allows customization of every automated wash system detail, enabling operators to tailor services for commercial fleets, passenger vehicles, or specialty treatments.

Water Efficiency

Commercial car washes are designed for water conservation, using significantly less water than home washing. While home washing may seem economical, it can consume up to 150 gallons per wash compared to about 50 gallons at professional facilities. This efficiency is achieved through water reclaim, filtration, and recycling systems that reduce waste, lower costs, and support water conservation regulations.

Water quality is crucial for effective car washing. Modern operators employ innovative technologies to recycle, purify, and treat wash water. Filtration systems remove contaminants to ensure spot-free results while meeting stormwater management requirements.

In response to environmental concerns, operators and manufacturers have adopted advanced water recovery technologies. Most systems now use closed-loop reclamation to retain water on-site, minimize wastewater discharge, and protect municipal water supplies.

Water Treatment Systems

Water treatment has become fundamental for sustainable car wash operations. As eco-friendly practices gain importance, advanced water treatment is now essential for compliance and cost savings. These solutions support environmental initiatives while reducing utility expenses and creating marketing opportunities for green-conscious businesses. They also help operators comply with environmental regulations and attract environmentally aware customers.

Reverse Osmosis (RO) System

RO systems use pressure to force water through semipermeable membranes, removing up to 99% of dissolved solids. This produces crystal-clear rinses that leave no spots on glass, paint, or chrome surfaces. RO water enhances protective coatings and hydrophobic effects, leading to higher customer satisfaction.

Water Reclaim System

Reclaim systems capture, treat, and reuse wash water. In these systems, water is drawn from settling tanks, treated to remove contaminants, and recirculated. Closed-loop designs continuously recycle water within the facility, supporting zero-discharge operations.

Water Restoration System

Restoration systems use cyclonic filtration to remove particles as small as five microns. The spinning action separates solids from water, ensuring thorough contaminant removal. This protects equipment and ensures water meets final rinse quality standards. Multi-stage filtration is often combined for maximum efficiency and compliance.

Water Storage Tanks

Storage tanks are vital for car wash systems, holding both fresh and recycled water. Underground tanks collect runoff, separate sediments, and allow pretreatment before recycling or disposal. Regular maintenance by licensed professionals ensures proper function and regulatory compliance.

Effective water management is crucial for car wash operations. Operators carefully monitor wastewater practices and tank maintenance, especially in drought-prone areas with water restrictions. This includes regular pipe and pump servicing to prevent operational disruptions.

Local water regulations significantly influence water management. Operators thoroughly understand and comply with regional conservation laws. This attention to regulations also affects maintenance, reporting, and system upgrades to meet changing standards.

Conveyor Systems

Conveyor systems represent advanced, high-volume car wash solutions. These tunnel systems use integrated belts or chains to move vehicles through multiple cleaning stages with precision and automation. Engineered for consistency, they're ideal for high-throughput operations.

Conveyor tunnels combine cleaning technology with automated engineering for optimal workflow. Manufacturers offer proprietary designs with customized drives, sensors, and controls for maximum efficiency.

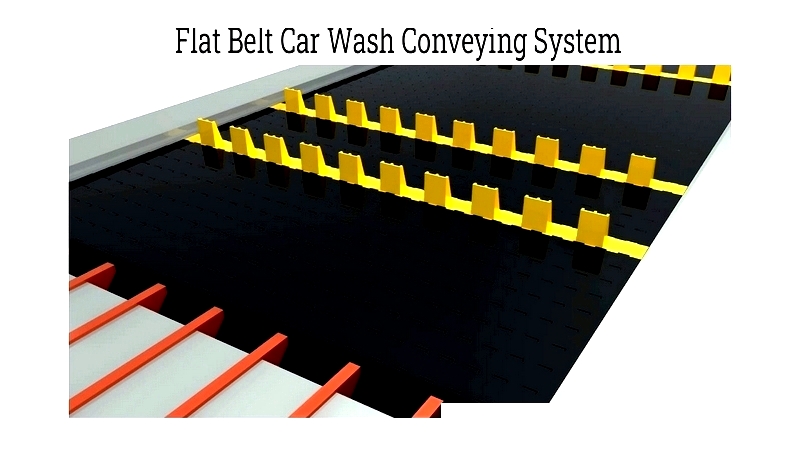

Flat Belt Conveyor

Flat belt systems transport vehicles without guide rails, protecting wheels and suspensions. Adjustable for speed and curvature, they accommodate various vehicle sizes. Lightweight belts handle up to 160 lbs/inch width, while industrial models support heavier loads.

These systems feature anti-static polypropylene belts with pusher cleats for multi-vehicle handling. Built-in lubrication and debris removal extend belt life. The full-contact platform engages all wheels, reducing alignment issues and vehicle damage risks.

As vehicles enter, all wheels engage the belt. Unlike rail systems, flat belts prevent wheel misalignment and tire damage. The standard 30-inch width with half-inch clearance ensures safe, efficient operation.

Chain Conveyor Systems

Chain systems use heavy-duty rollers and adjustable chains for reliable high-volume operation. Compatible with hydraulic or electric drives, they feature easy-length-adjustment mechanisms for wear compensation.

Chains guide vehicles by pulling front wheels or pushing rear wheels. Alignment systems with entry correlators minimize damage risks. Protective guide rails shield undercarriages, while drive systems balance power needs with smooth operation.

High Pressure Washer

High-pressure washers use rotating jets and multi-angle nozzles to remove tough contaminants. Delivering up to 1000 psi, they prepare surfaces for subsequent cleaning or waxing stages. Booster pumps maintain consistent powerful flow for thorough cleaning without surface damage.

Adjustable pressure and flow controls accommodate various vehicle types, from compact cars to large trucks. This design serves as both pre-wash and primary cleaning for heavily soiled vehicles.

Brushes and Scrubbers

Brushes are essential automatic wash components, available in various configurations. Tunnel systems use overhead top brushes for roofs and hoods, plus wraparound brushes for side surfaces.

Wheel and tire brushes target lower areas with specialized designs for deep cleaning. Materials range from soft cloth to durable poly bristles that clean effectively without scratching.

Synthetic composite brushes offer durable, gentle cleaning for all vehicle types. Available in multiple colors and sizes, they allow branding integration and tunnel optimization.

Wax Arch

Wax arches apply protective coatings to enhance shine and protect surfaces. Application methods include foam generators or spray nozzles, each offering distinct advantages for coverage and durability.

Foam applicators produce dense wax for even tunnel distribution. Nozzle systems spray liquid wax for quick bonding. Both methods can be combined for premium service options.