Introduction

This section describes various types of 55-gallon drums, including manufacturer listings and common applications.

You will learn about:

- The definition of a 55-gallon drum

- Manufacturing processes for 55-gallon drums

- Common applications of 55-gallon drums

- Different types of 55-gallon drums

- Reconditioning and refurbishing processes

- Additional relevant information

Chapter 1: Understanding the 55-Gallon Drum

The 55-gallon drum is a sturdy cylindrical container designed for storing various materials including chemicals, powders, grains, and liquids. Manufacturers produce these drums using different materials such as galvanized steel, stainless steel, carbon steel, and hardened steel, with material selection depending on the intended contents. Alternative materials include durable plastics, fiberboard, and cardboard.

Originally, 55-gallon drums were wooden containers used for crude oil transportation.

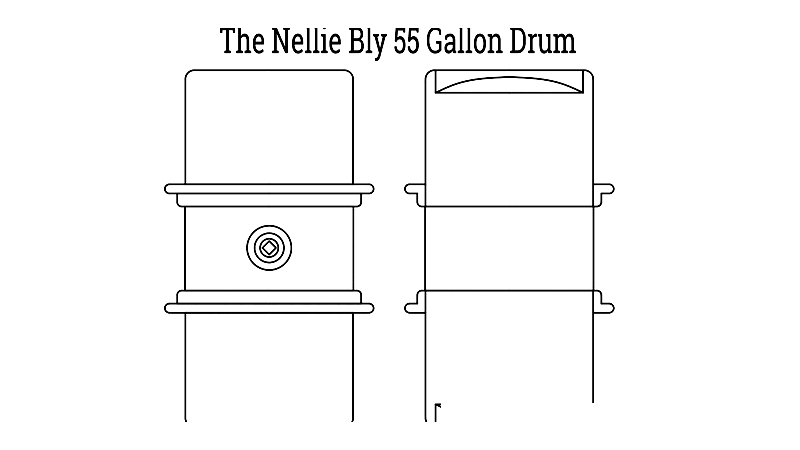

However, wooden barrels proved inadequate for continuous use due to size and strength limitations, especially when bulk transport primarily relied on rail and ships. Elizabeth Cochran Seaman, known as Nellie Bly, developed a more stable solution by inventing a ribbed steel 55-gallon drum, which she patented as an improved oil storage container.

Initially used exclusively for oil transport, the Nellie Bly drum's application expanded during World War I when sulfuric acid transportation became necessary. The original steel construction proved too thin for acid containment, leading to accidents. Charles Draper subsequently developed a double-sealing mechanism for 12-gauge steel drums, enabling safe storage of caustic acids. This innovation revolutionized drum manufacturing and established the foundation for modern 55-gallon drums.

Chapter 2: Manufacturing Process of 55-Gallon Drums

In industrial packaging, the terms "drum" and "barrel" are often used interchangeably, though they have distinct origins. While "barrel" historically refers to crude oil measurement, "drum" is the preferred term for standardized cylindrical containers in modern industry. These robust containers are designed for transporting and storing liquids, chemicals, powders, and hazardous materials.

Manufacturers produce 55-gallon drums from various materials selected for specific properties. metal drums typically use carbon steel, stainless steel, or cold-rolled steel for strength and corrosion resistance. Plastic versions employ materials like HDPE or PVC for chemical resistance and lightweight handling. Fiberboard drums offer a cost-effective alternative for dry goods storage.

metal Drums

Steel drums play a crucial role in global supply chains, particularly for shipping chemicals, oils, and industrial powders. These containers meet strict UN/DOT regulations for hazardous materials transport.

Top and Bottom Construction

Manufacturing begins with stamping drum ends from steel coils using punch presses. The process ensures precise fitting with the cylindrical body. Protective coatings enhance corrosion resistance, while bung and vent holes facilitate filling and emptying operations.

Body Formation

The cylindrical body forms from sheet metal rolled and welded into shape. Quality inspections verify seam integrity to meet international safety standards.

Assembly Process

The chime process creates airtight seals between components. Closed-head drums feature permanent tops with bung openings, while open-head versions have removable lids secured by rings.

Final Finishing

Protective coatings and color coding enhance identification and compliance with industry standards. Automated systems ensure uniform application and rapid curing.

Plastic Drums

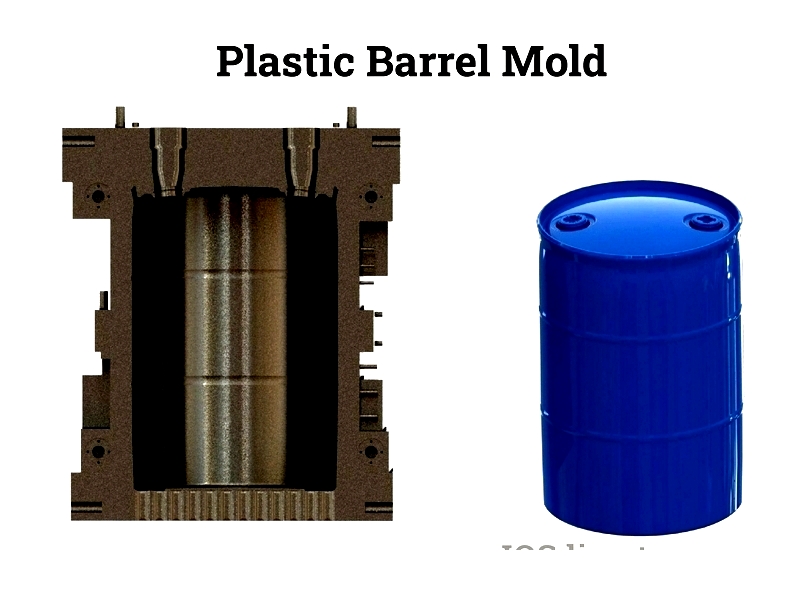

Plastic drums offer chemical resistance and lightweight handling. Common manufacturing methods include blow molding and rotational molding.

Blow Molding

This process uses compressed air to form plastic resins into drum shapes. Quality testing ensures compliance with industry standards.

- Extrusion - Melts resin pellets for parison formation

- Parison - Inflates within mold to create drum shape

- Mold - Engineered for uniform wall thickness

- Ejection - Final product undergoes quality checks

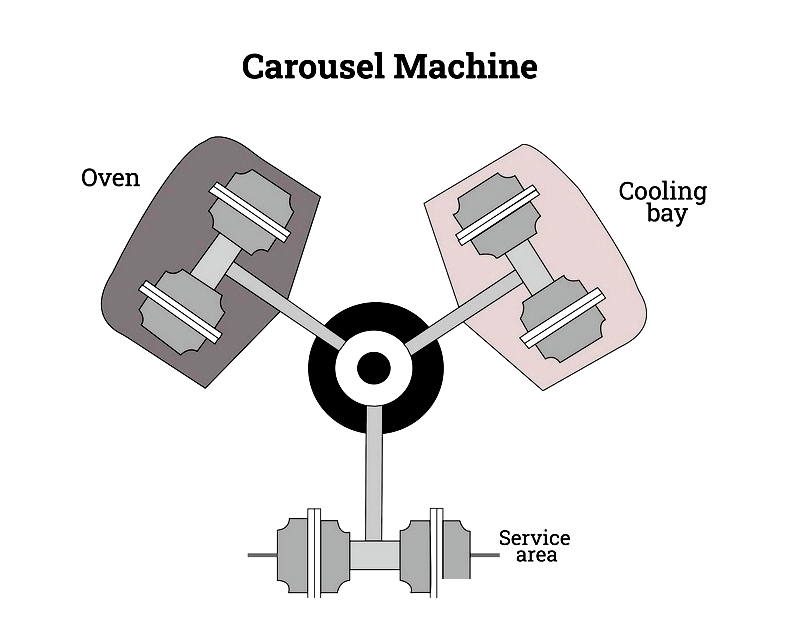

Rotational Molding

This method produces seamless drums with consistent wall thickness, ideal for harsh environments.

Fiber Drums

Fiber drums use kraft paper and adhesives to form lightweight containers. They often include liners for moisture protection.

Chapter 3: Applications of 55-Gallon Drums

These versatile containers serve multiple industries including petroleum, food processing, pharmaceuticals, and chemical manufacturing.

Petroleum Industry

Drums revolutionized oil transport, replacing less efficient wooden barrels. They remain standard for smaller petroleum product shipments.

Food Industry

Food-grade drums ensure safe storage of ingredients and comply with FDA standards.

Pharmaceutical Industry

Specialized drums maintain product purity and meet strict handling requirements.

Chemical Industry

Chemical-resistant drums provide safe containment for hazardous materials.

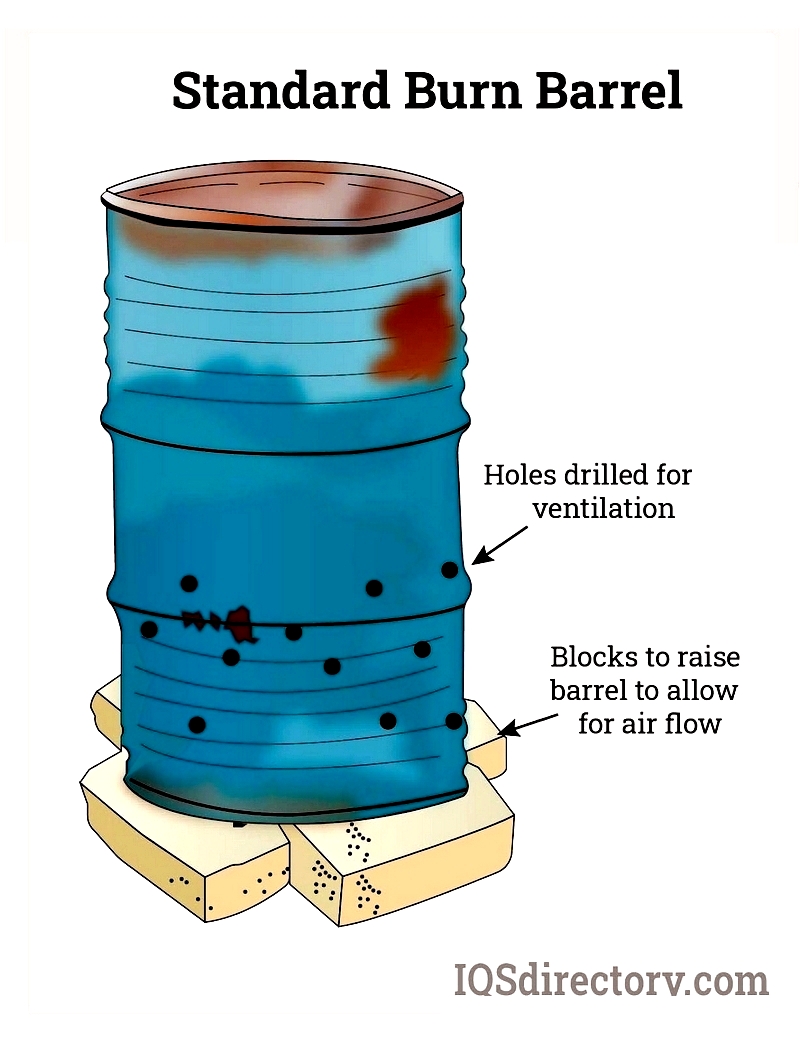

Burn Barrels

Modified steel drums enable controlled waste incineration in rural areas.

Water Barrels

Rainwater collection systems utilize durable plastic or metal drums for water conservation.