Introduction

This comprehensive guide covers everything you need to know about sinker EDMs and their applications.

Key topics include:

- Sinker EDM Fundamentals

- Different Types of Sinker EDMs

- The Sinker EDM Process Explained

- Components of Sinker EDMs

- Practical Applications of Sinker EDMs

- Additional Insights

Chapter One: Understanding Sinker EDM

Sinker Electrical Discharge Machining (EDM) is a precision metalworking technique that creates molds, dies, and complex components through controlled electrical erosion. This method excels at producing intricate shapes with exceptional accuracy and consistency compared to conventional machining processes.

The term "sinker EDM" derives from the process's ability to gradually penetrate materials through controlled erosion. Often called "burning," this technique forms microscopic craters to shape the workpiece. Effective sinker EDM requires the material to be electrically conductive, typically ferrous alloys.

Chapter Two: The Sinker EDM Process

Manufacturers prefer sinker EDM for its ability to precisely machine extremely small and complex components. This process is particularly effective for creating intricate metal parts and dies that would be challenging or impossible to produce using traditional methods like CNC milling. Its versatility makes it ideal for producing undercuts, sharp internal corners, and fine details in tool and die making, injection molding components, aerospace parts, and medical devices. Sinker EDM is also valuable for prototyping and design refinement before mass production.

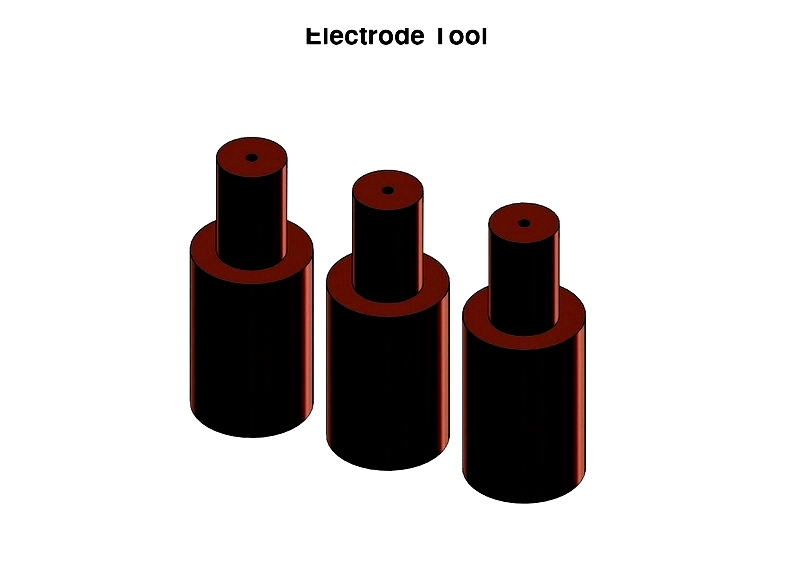

Electrode Design

The first critical step in sinker EDM machining involves designing the electrode, typically made from copper or graphite. The electrode's shape directly corresponds to the desired final geometry, influencing accuracy and surface finish. Mounted on the machine's holder and connected to the power supply, the electrode's design affects parameters like material removal rate, surface roughness, and process stability. High-precision applications often require multiple electrodes, each sparking independently to minimize thermal distortion.

Electrode selection depends on feature complexity, batch size, tolerance requirements, and cost considerations. Common types include:

- Staged Electrodes: These use progressively higher-quality materials to refine the shape and improve surface finish.

- Pieced Electrodes: Cost-effective alternatives to solid electrodes, featuring aluminum-backed graphite components that can be individually replaced.

- Partial Area Electrodes: CNC-compatible electrodes that allow precise machining of specific workpiece areas.

Modern EDM electrode design utilizes advanced CAD/CAM software for precision modeling and simulation, streamlining production.

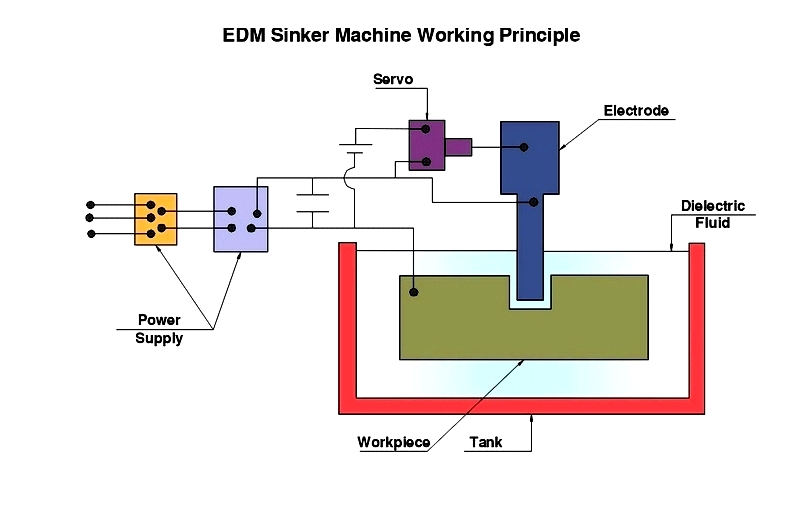

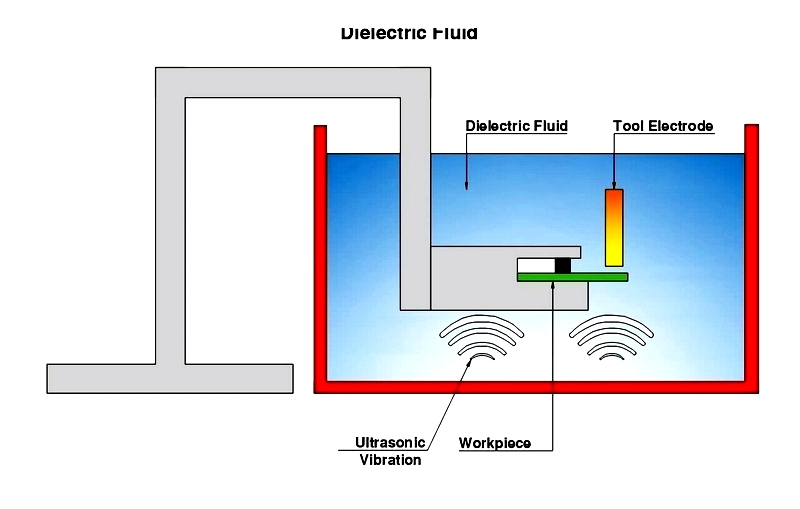

Dielectric Fluid Preparation

In EDM machining, dielectric fluid serves multiple critical functions: cooling, electrical insulation, debris removal, and process stabilization. This specialized fluid circulates between the electrode and workpiece, preventing arcing, removing eroded particles, and maintaining machining gap integrity. It also regulates temperature to ensure consistent erosion rates.

Common dielectric fluids include petroleum-based oils or synthetic blends, with eco-friendly options available for specific applications. Ideal fluids offer high electrical resistance and low viscosity to enhance spark stability and material removal. Continuous filtration and monitoring maintain fluid purity, essential for process consistency and part quality.

Effective dielectric management extends electrode and machine life while supporting tight tolerances and superior surface finishes.

Workpiece Preparation

Successful sinker EDM requires electrically conductive workpieces, typically hardened steels, exotic alloys, carbides, or titanium. Proper preparation involves thorough cleaning to remove contaminants that could affect spark formation or machining accuracy. The workpiece may be immersed in deionized water or treated with non-conductive lubricant to facilitate material removal and maintain spark uniformity.

Continuous dielectric fluid circulation, supported by pumps and filtration systems, cools the work area and removes debris. Maintaining stable fluid conditions is crucial for process repeatability and surface integrity, particularly in precision applications for aerospace, medical, and electronics industries.

Electrode Positioning

The electrode is precisely aligned with the workpiece, maintaining a controlled gap for electrical discharges. CNC-controlled positioning ensures micron-level accuracy without physical contact, preventing mechanical force-related distortions. This non-contact method is ideal for delicate or brittle materials.

Proper positioning is essential for feature replication, surface finish quality, and consistent electrode-to-workpiece clearance. The electrode, typically copper or graphite, is machined as a negative replica of the desired feature.

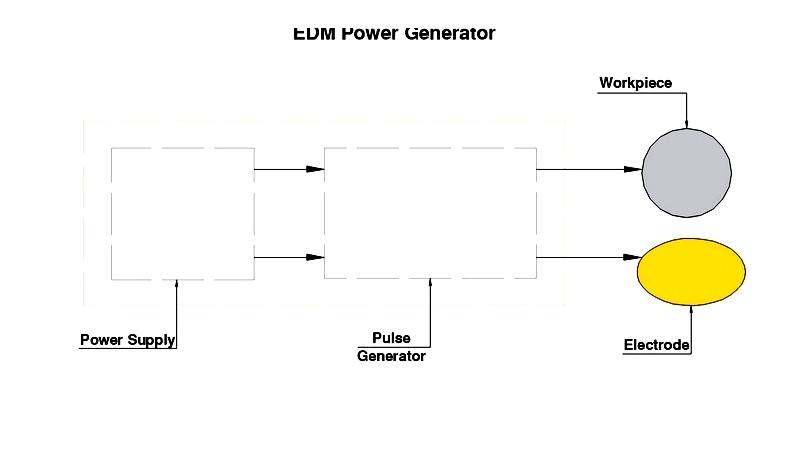

Spark Initiation

A high-voltage electrical discharge creates controlled sparks that erode the workpiece according to the electrode's shape. These microscopic sparks reach extreme temperatures (8000°C to 12000°C), vaporizing material to reproduce intricate geometries with tight radii and fine details.

This process distinguishes sinker EDM from other machining methods, enabling production of hardened dies, precision molds, stamping tools, and microcomponents.

Spark Control

Sinker EDM parameters—amperage, voltage, spark gap, and pulse duration—directly influence material removal rate, surface finish, accuracy, and electrode wear. Each spark pulse is carefully controlled to maintain efficiency and prevent defects. Higher energy settings increase removal rates but produce larger debris particles, requiring effective dielectric flushing.

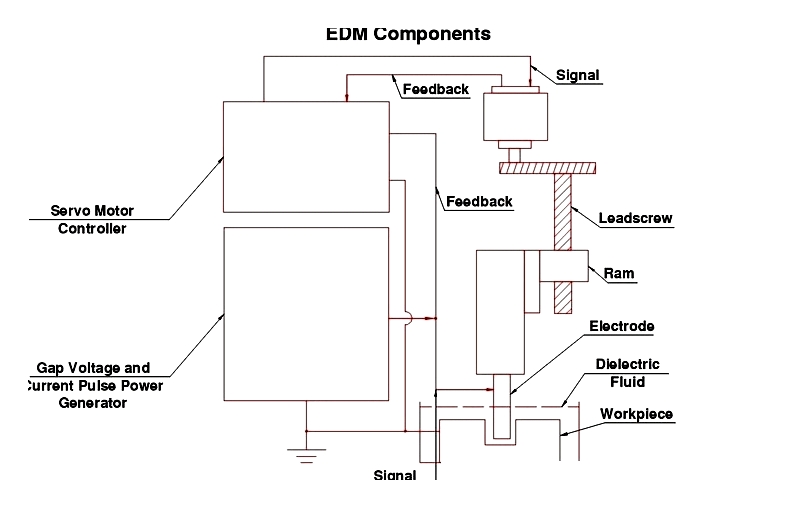

Advanced CNC sinker EDM machines continuously optimize power settings through feedback systems, accommodating both roughing and finishing requirements.

Process Monitoring

Modern sinker EDM machines incorporate CNC controls and real-time monitoring systems to track spark gap voltage, plasma conditions, and electrode wear. Sensors detect process anomalies, automatically adjusting parameters to maintain quality and extend tool life.

This data-driven approach minimizes downtime and rework, particularly beneficial for high-volume precision manufacturing in aerospace, automotive, and medical industries.

Workpiece Finishing

Sinker EDM produces smooth, uniform surfaces, often requiring minimal additional finishing. For demanding applications, secondary processes may include:

- Painting: Powder coating, liquid coating, or e-coating for protection and aesthetics

- Transfers: Graphic applications for branding or identification

- Assembly: Integration into larger components

- Drilling: Additional hole creation as needed

- Deburring: Edge refinement for safety and performance

Combining sinker EDM with appropriate finishing techniques ensures dimensional accuracy, surface quality, and component longevity for various applications.

Chapter Three: Sinker EDM Variations

Sinker EDM, also called conventional or cavity-type EDM, excels at machining hard, conductive metals with minimal thermal distortion. Originally developed in 1943, this process has become essential for manufacturing complex molds, dies, and precision components.

Small Hole EDM

This variation uses rotating hollow electrodes to create precise holes in hard materials. Ideal for turbine blades and fuel injectors, it offers superior accuracy compared to mechanical drilling, especially for inclined or hard-to-reach surfaces.