Introduction

This article provides an in-depth exploration of climate chambers and their applications.

You will learn about various aspects including:

- What a Climate Chamber is

- Applications of Climate Chambers

- Different Types of Climate Chambers

- Climate Chamber Construction

- And More...

Chapter One – What is a Climate Chamber?

A climate chamber is an enclosed space designed to simulate and control various environmental conditions for testing how industrial products, electronics, materials, and biological samples respond.

These chambers can test factors like temperature variations, humidity effects, light exposure, and thermal shocks. They operate in two modes: constant (maintaining steady conditions) and dynamic (varying conditions during testing).

To evaluate product durability during transportation and storage, various tests determine failure points and endurance limits. Climate chambers enable long-term, stability, accelerated, and stress testing, providing reliable performance data.

Chapter Two – Types of Climate Chambers

Choosing the right climate test chamber is crucial for product development, quality assurance, and compliance testing. Key considerations include sample type, required environmental parameters, test protocols, and industry regulations.

Modern climate test chambers simulate diverse conditions like thermal extremes, humidity, corrosion, vibrations, and thermal shock. They're essential for automotive, electronics, aerospace, pharmaceutical, and materials science industries.

Climate Chamber Types

Benchtop Climate Chambers

Benchtop climate chambers offer compact solutions for space-constrained labs. They support temperature/humidity cycling, rapid screening, and material compatibility tests with precision controls.

Their durable steel construction and portability make them ideal for component testing, material evaluation, and multi-site studies.

Constant Climate Chambers

Constant climate chambers maintain stable conditions for long-term stability studies and shelf-life testing, with precise temperature/humidity control.

They're vital for pharmaceuticals, food packaging, and electronics, helping meet GMP and IEC standards.

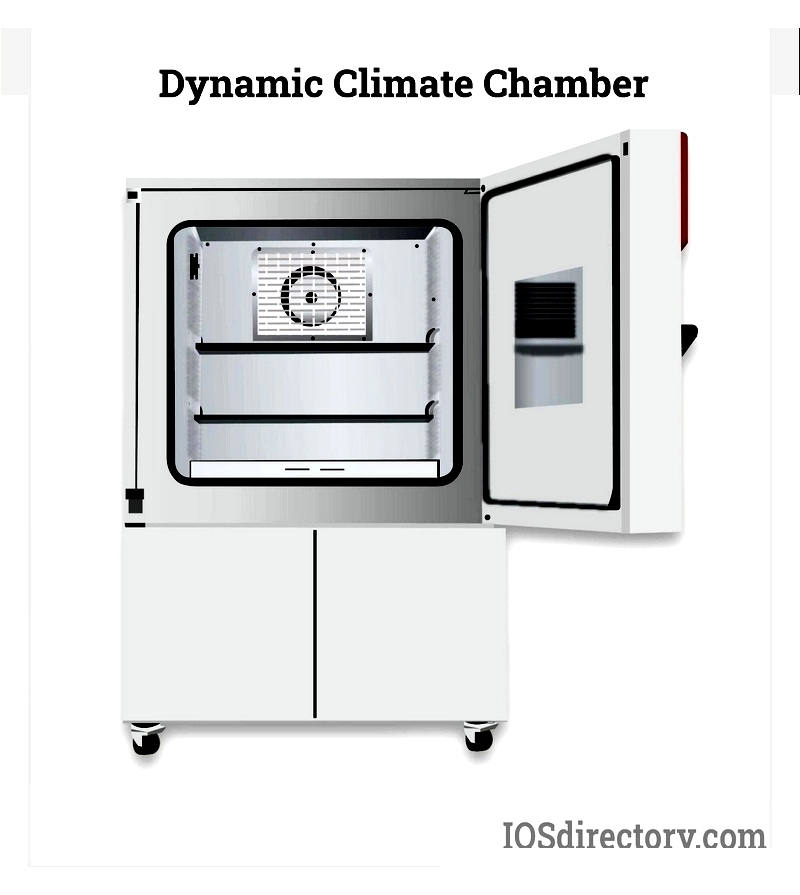

Dynamic Climate Chambers

Dynamic climate chambers simulate rapid environmental changes for thermal cycling and stress screening of electronics and automotive components.

They help identify design weaknesses before production, reducing recalls and improving product reliability.

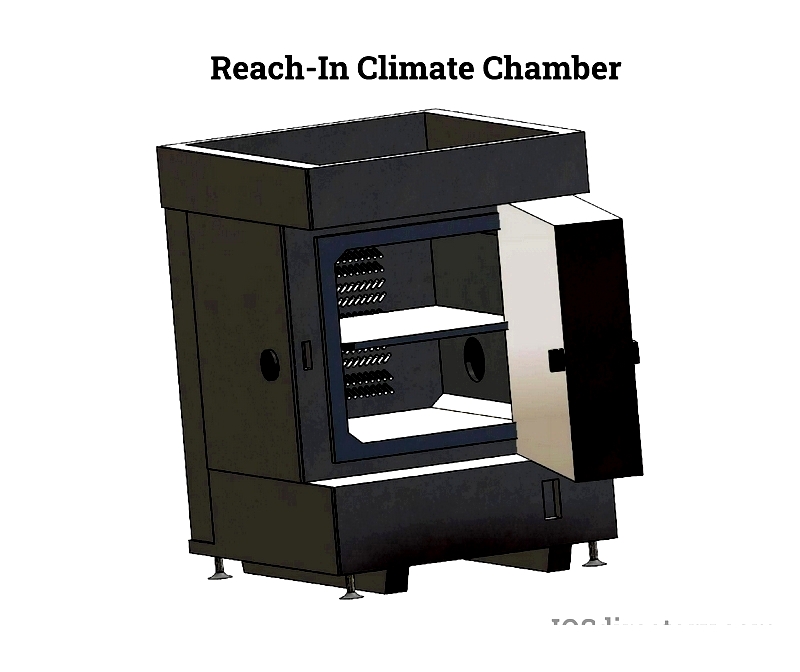

Reach In Climate Chambers

Reach-in chambers offer medium capacity (4-70 cu.ft) for biological research, plant studies, and pharmaceutical testing with customizable configurations.

Ideal for seed germination, package testing, and accelerated shelf-life studies.

Stability Climate Chambers

Stability chambers provide precise temperature/humidity control for pharmaceutical, food, and cosmetic stability testing.

They support long-term, ongoing, accelerated, and stress testing to ensure product quality and compliance.

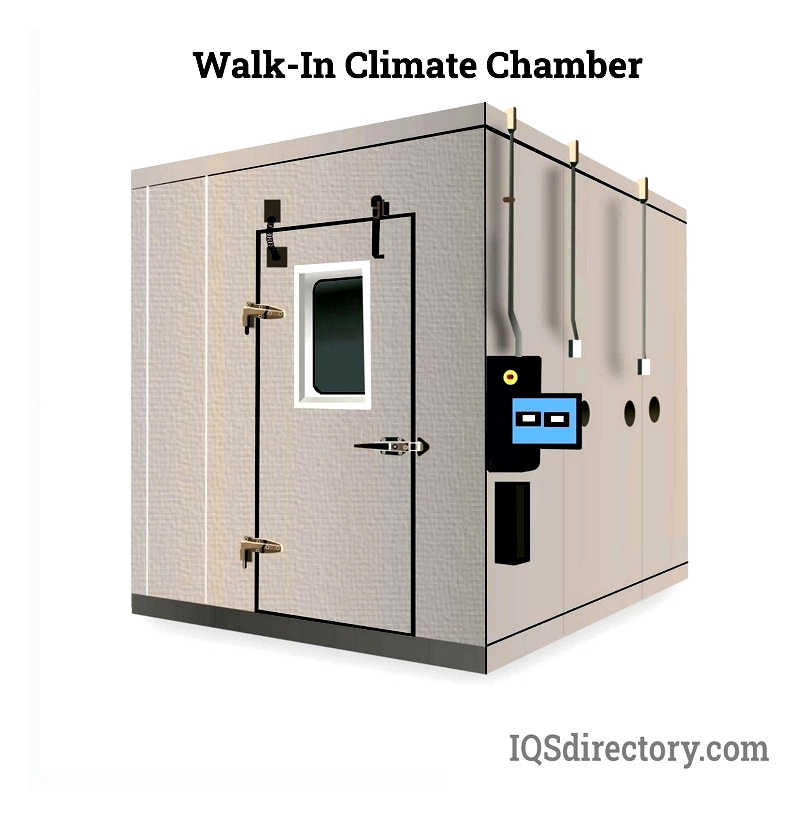

Walk-In Test Chambers

Walk-in chambers accommodate large-scale testing with customizable environments (-65°C to 180°C, 10-95% humidity).

Used for automotive, aerospace, and electronics testing, they feature advanced controls for automated testing and compliance reporting.