Introduction

You'll find the best die stamping information available online here.

Here's what you'll learn:

- The fundamentals of die stamping

- Different die stamping types (progressive vs. transfer)

- Common metals used in die stamping

- Additional valuable information

Chapter One – Understanding Die Stamping

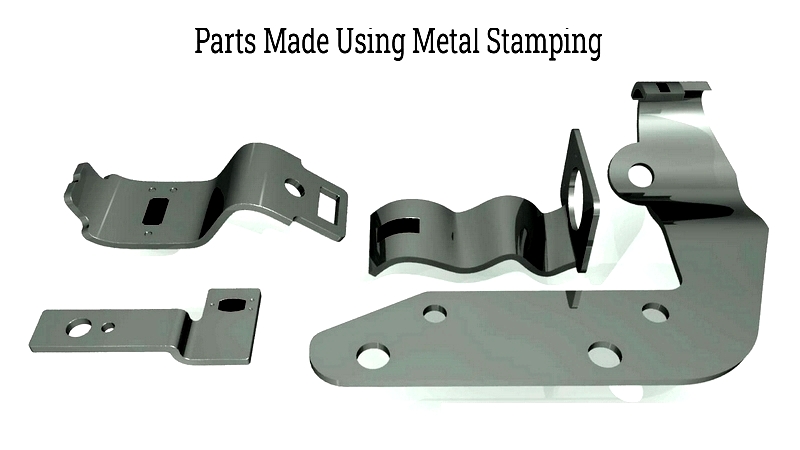

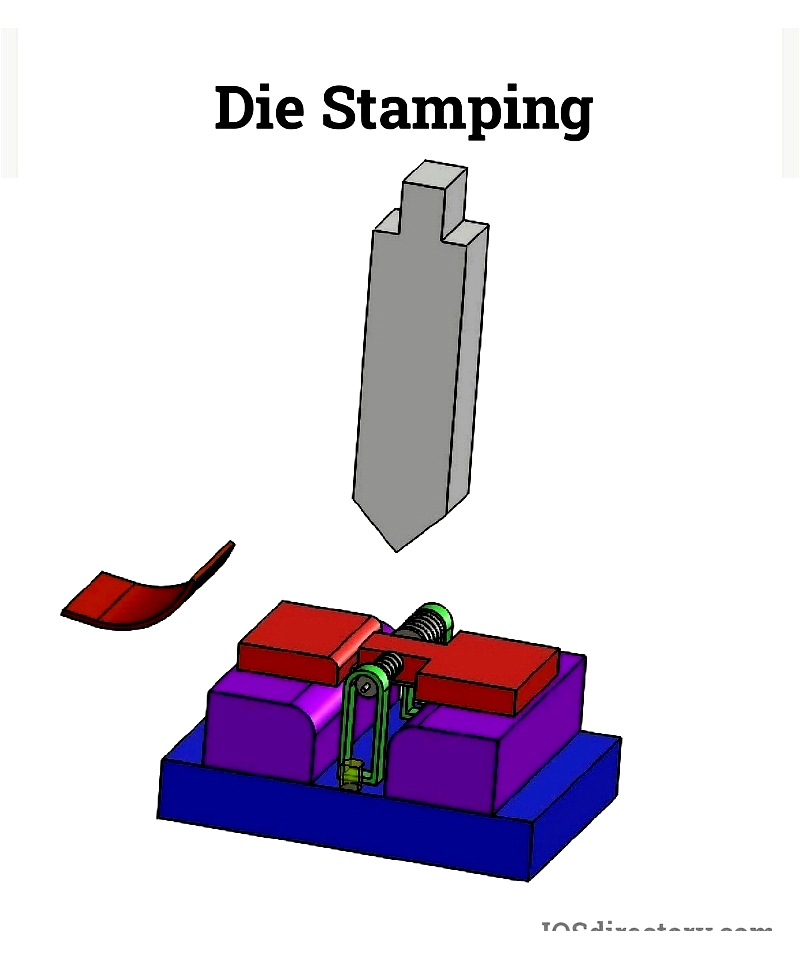

Die stamping is a cold forming process that begins with a metal strip, typically called a blank or tool steel. Using specialized dies, this technique shapes and cuts metal into specific designs or profiles. The applied force modifies the blank's structure and geometry, enabling the creation of complex shapes. This versatile method can produce metal parts ranging from tiny components to large-scale products, depending on application needs.

Also referred to as pressing, die stamping encompasses various techniques including blanking, punching, piercing, and coining. Precision design is essential to ensure each operation delivers high-quality results.

Die stamping tools are custom-made to create specific designs, from simple everyday objects to intricate electronic components. These tools may serve single purposes or function within multi-stage sequences to perform various operations.

The three primary die stamping processes are:

- Line: A single-operation process

- Transfer: Multiple stamping operations completed in one cycle

- Progressive: The most widely used method

(These processes will be explored in detail in Chapter 3: Production Methods).

Chapter Two – Die Stamping Operations

Stamping dies serve two main functions in metal fabrication: cutting and forming. Advanced combination dies can perform both actions in a single stroke. These operations enable manufacturers to separate sheet metal or shape it into complex geometries through controlled deformation. Understanding these processes is crucial for industries requiring reliable, cost-effective solutions in automotive, appliance, electronics, and other manufacturing sectors.

Forming Dies Include:

- Bending

- Flanging

- Drawing

- Stretching

- Coining

- Ironing

Cutting Dies Include:

- Shearing

- Blanking

- Trimming

- Notching

- Piercing

Forming dies compress and manipulate sheet metal into precise shapes, functioning like stencils to produce consistent results. These operations are vital for high-volume production in industries like aerospace, medical devices, and automotive manufacturing.

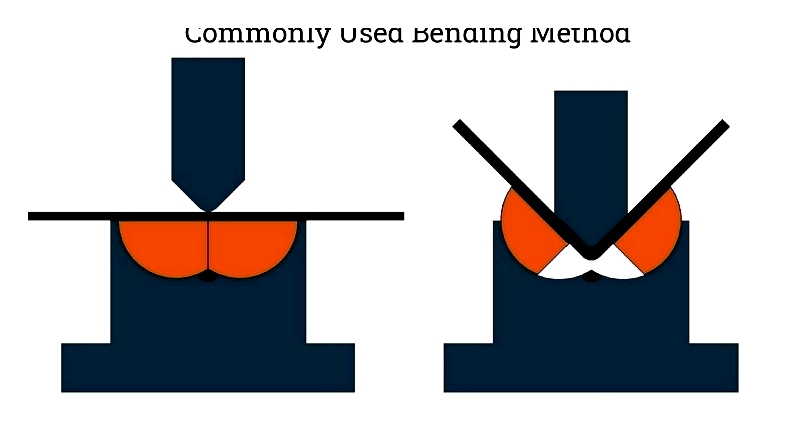

Bending

Bending creates basic and complex shapes (L, U, or V profiles) by applying controlled force along a single axis. This fundamental metalworking process is widely used for brackets, enclosures, and automotive components. Automated CNC press brakes ensure precise, repeatable bending angles across various materials including stainless steel, aluminum, and copper alloys.

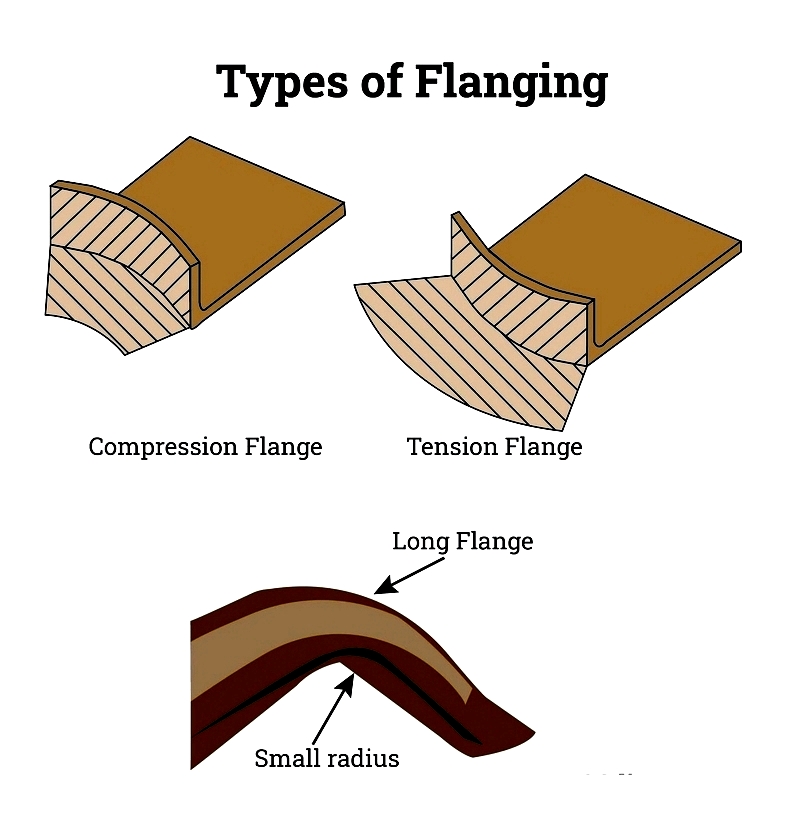

Flanging

Flanging bends workpiece edges along curved axes, with two main types: stretching and shrinking. This process shapes metal using tension and compression forces, ideal for creating curves, corners, or reinforced features. Commonly used in automotive, aerospace, and appliance industries, flanging offers efficient, accurate solutions for mass production.

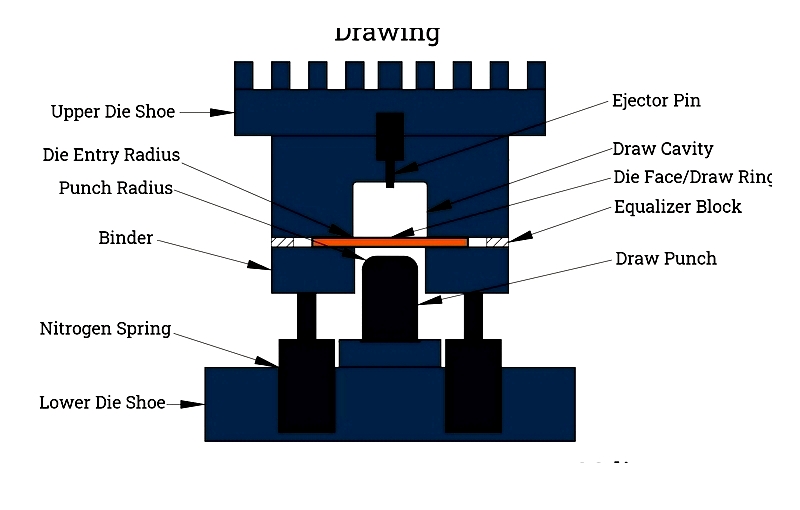

Drawing

Drawing transforms flat sheet metal into hollow components by forcing material to flow radially while maintaining surface area. This process creates cylindrical, box-like, or complex shapes with consistent wall thickness. Deep drawing, where depth exceeds diameter, produces seamless items like beverage cans and automotive housings.

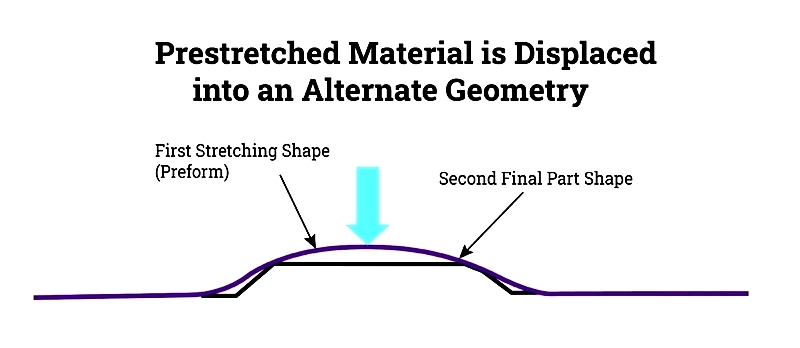

Stretching

Stretch forming increases metal surface area through tension, creating smooth surfaces ideal for painting and coatings. This process produces durable components resistant to warping, commonly used for aerospace skins, automobile panels, and architectural elements.

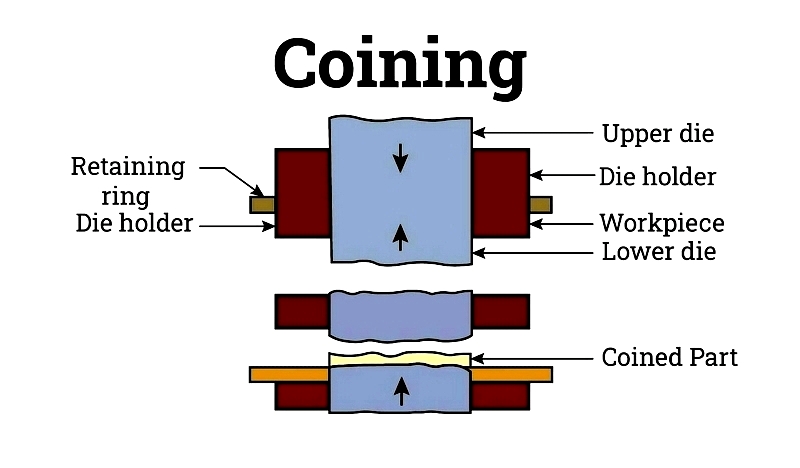

Coining

Coining uses high pressure to imprint patterns while reducing metal thickness. This precise method creates intricate details for currency, medallions, gears, and decorative hardware, offering sharp definition and consistency.

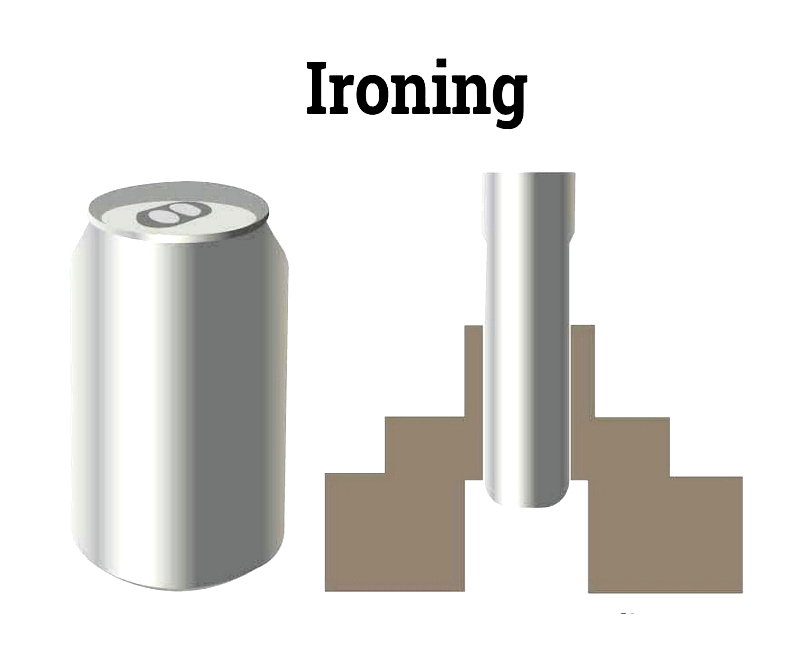

Ironing

Ironing standardizes wall thickness in cylindrical parts like cans, typically reducing material by 30%. Combined with deep drawing, this process produces lightweight, robust containers for high-speed manufacturing.

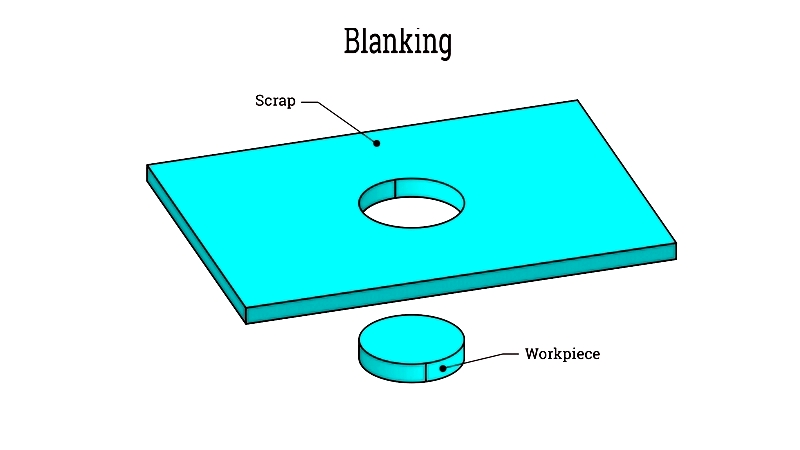

Blanking

Blanking removes metal sections along specific contours to create workpieces. The remaining material becomes scrap, though often recyclable. This operation is essential for industries requiring consistent part geometry for assembly or further processing.

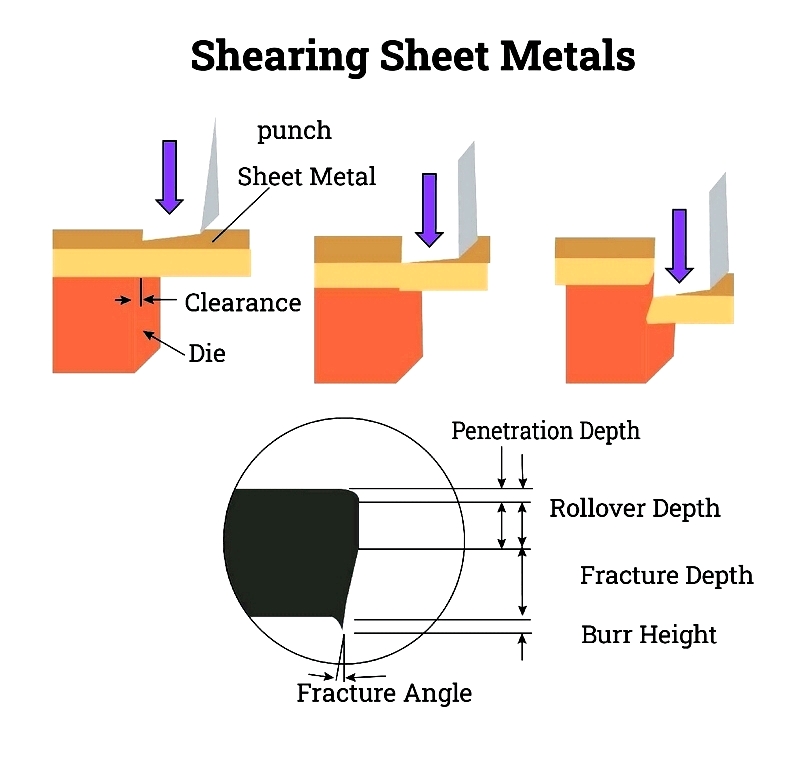

Shearing

Shearing makes straight cuts in sheet metal for rectangular, square, or custom shapes. This versatile process supports structural projects and electrical enclosures, with automated equipment enabling high production rates.

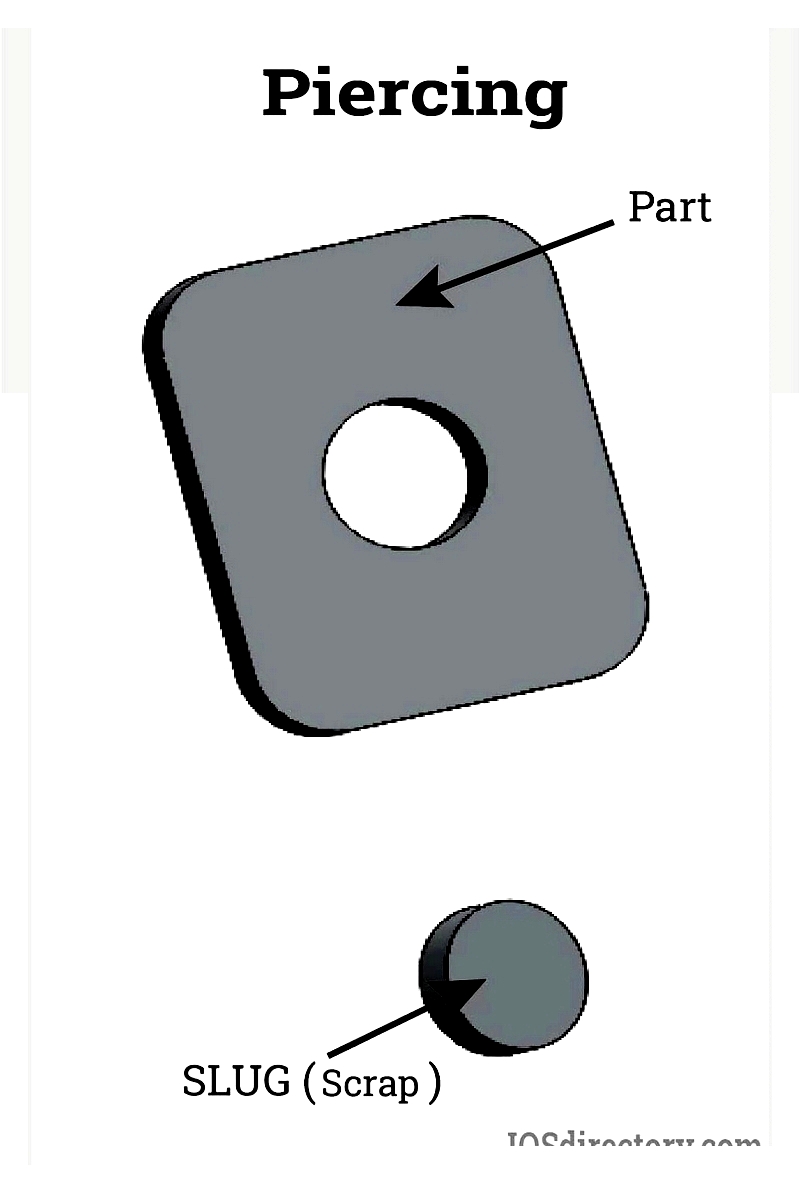

Piercing

Piercing creates holes or internal features using punch and die sets. Unlike blanking, the punched material becomes scrap. This precision operation is crucial for panels, brackets, and electronic housings requiring exact hole placement.

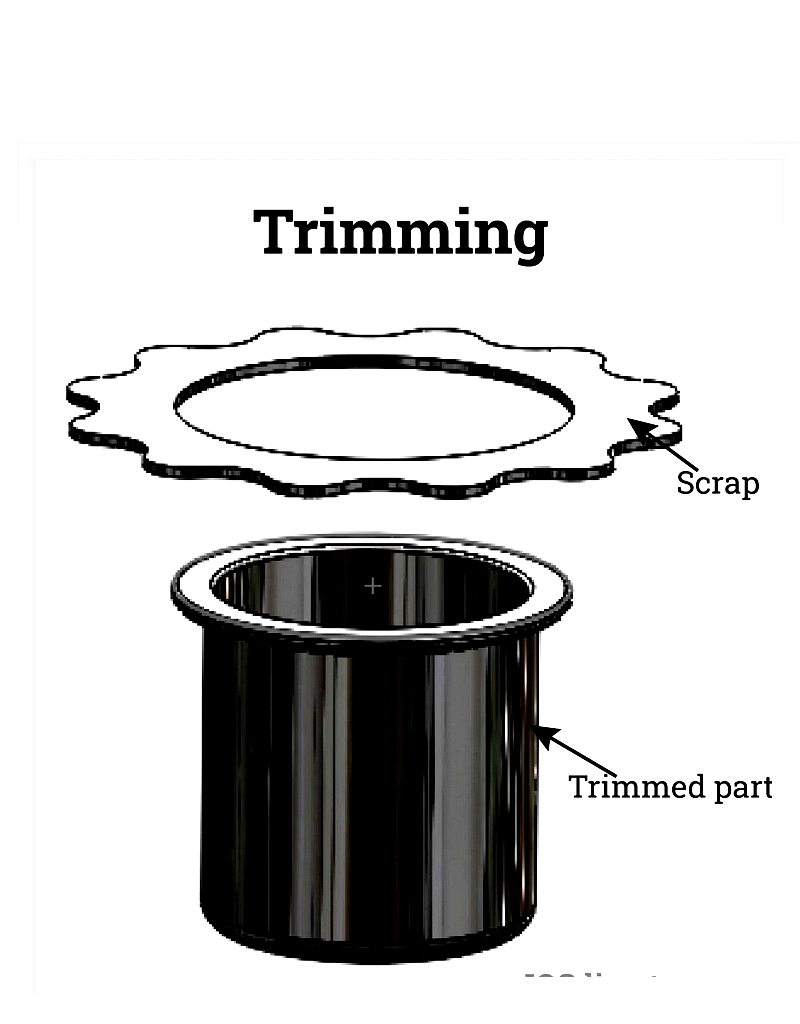

Trimming

Trimming removes excess material from formed parts, ensuring clean edges for subsequent processes. Automated trimming maintains consistency in mass production for industries requiring precise dimensional accuracy.

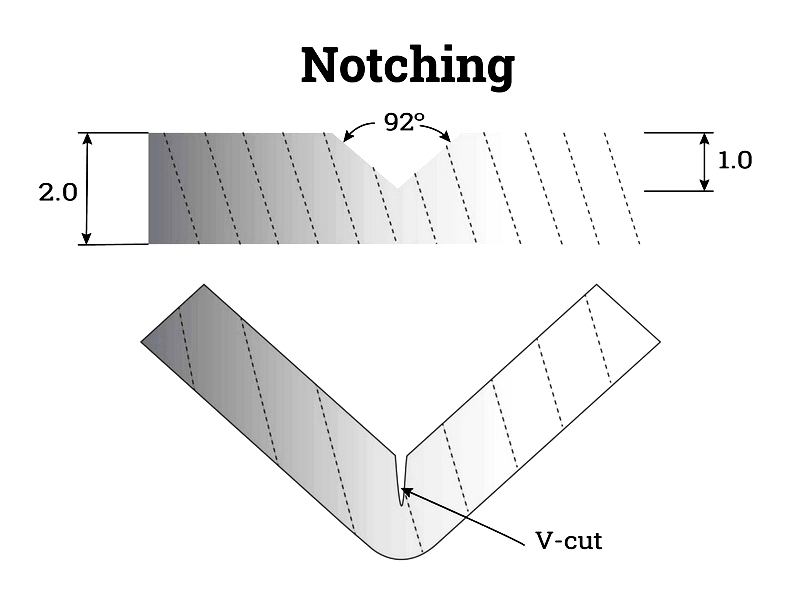

Notching

Notching prepares workpieces for bending or forming by creating edge cuts. This technique simplifies assembly and shaping for metal frames, supports, and enclosures requiring precise fitment.

These twelve operations represent just a portion of available die stamping techniques. Custom solutions address complex geometries, tight tolerances, and specialized materials. Consulting experienced manufacturers helps select optimal processes for consistency, cost-efficiency, and faster production.

Understanding these core operations enables informed decisions for quality, cost-effective