Introduction

This article provides an in-depth exploration of CNC milling.

You will learn about various topics including:

- The CNC process

- CNC milling process

- Types of milling operations

- Specialized milling operations

- Components of CNC milling equipment

- CNC milling machine tools

- Vertical and horizontal milling

- Different types of milling machines

- Materials processed by CNC milling

Chapter One: Understanding the CNC Process

The CNC (Computer Numerical Control) process originated in the 1950s and saw significant advancements in the 1980s with the integration of computer technology. Unlike traditional manufacturing methods, CNC begins with a digital design that creates a 2D or 3D representation of the desired component. Computer-Aided Design (CAD) software generates the instructions that guide CNC machines throughout production.

CAD software precisely defines the dimensions and specifications required for the component. Engineers and designers use this tool to create prototypes that can be reviewed, refined, and approved. This technology allows for thorough design analysis without immediate physical prototypes, saving time and reducing labor costs. Many modern products originate from CAD-designed prototypes.

After design validation, the data must be converted into machine-readable code. Computer-Aided Manufacturing (CAM) software handles this conversion, translating instructions into standard codes like G-Code or M-Code.

The processed data moves to production for CNC machine setup and program loading. Machine preparation includes tool installation, material placement, and test runs. once programmed, the CNC machine automatically executes instructions to produce finished components.

The CNC process can shape various materials including metals, plastics, glass, and wood. It enables rapid production of custom parts with precise specifications. Modern manufacturing heavily relies on CNC for efficient, cost-effective production.

CNC milling is the most common CNC application, first implemented in 1952. As one of the oldest manufacturing methods dating to the early 19th century, milling complements CNC technology perfectly since both focus on material removal from workpieces.

Chapter Two: The CNC Milling Process

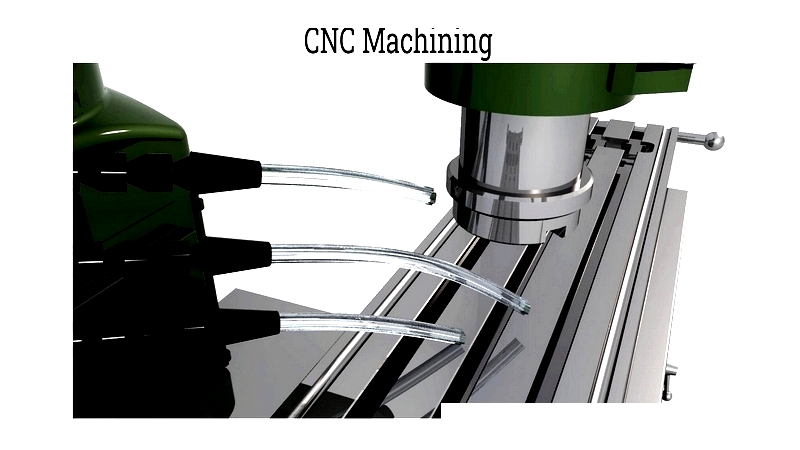

CNC milling is a precise, computer-controlled manufacturing method that converts digital designs into physical parts. The process begins by securing the workpiece (typically metal, plastic, or composite) on the machine's work surface or fixture. Operators then install appropriate milling tools (end mills or face mills) based on part geometry, material, and tolerance requirements.

After setup, the machine runs the CNC program generated from CAD/CAM software. This program controls all machining parameters, including tool and workpiece movement. Milling can occur in horizontal or vertical orientations, with multi-axis machines (3-5 axes) commonly used in advanced manufacturing sectors.

During operation, the workpiece moves precisely to allow material removal according to the digital design. Cutting approaches include feeding the workpiece into a stationary tool, moving the tool across a fixed workpiece, or coordinated movement of both. Most CNC mills use climb milling (tool rotation matches feed direction) for cleaner cuts and longer tool life, though conventional milling (opposite directions) suits certain applications.

CNC milling often serves as a finishing operation after initial machining processes. It adds precision features like holes, slots, threads, and complex geometries requiring tight tolerances. This subtractive manufacturing method achieves final shapes through controlled material removal.

The process typically begins with roughing (rapid material removal) followed by finishing passes (high-precision detailing). Complex parts may require multiple tool changes and setups. Modern CNC mills offer exceptional flexibility, with tools moving along multiple axes (X, Y, Z) and additional rotary axes enabling sophisticated 3D machining in single setups.

When selecting CNC milling services, consider machine rigidity, spindle power, tool capacity, and automation options. Many providers offer additional services like rapid prototyping, 3D modeling support, and real-time monitoring to ensure quality and efficiency.

For information about CNC milling solutions or custom part quotes, consult featured manufacturers below. As demand grows for precision components, CNC milling remains essential for advanced manufacturing across industries.