Introduction

This article provides an in-depth examination of perforated steel's uses and applications.

You'll explore key topics including:

- What is Perforated Steel?

- Manufacturing Process of Perforated Steel

- Perforated Steel Grades

- Pattern Variations in Perforated Steel

- And More...

Chapter One – What is Perforated Steel?

Perforated steel results from a metalworking process that creates patterns on flat-rolled steel sheets through punching or stamping. Originally developed for coal filtration with manually punched round holes, modern perforated steel production now employs advanced techniques including rotary pin perforation, die punch perforation, and laser perforation. Today, it serves as an essential material in both industrial applications and architectural designs, far surpassing its initial purpose.

This versatile material functions in structural support, acoustic management, light control, railing stabilization, and filtration systems. Its combination of strength, durability, and resilience makes it ideal for perforated sheet applications. The material's adaptability allows for extensive customization of patterns and designs while maintaining structural integrity, stability, and toughness.

Chapter Two – Manufacturing Process of Perforated Steel

Modern perforated steel production utilizes advanced metal fabrication techniques to create precise patterns of holes, slots, or shapes in steel sheets or coils. While the fundamental process involves punching metal sheets, achieving desired patterns requires careful planning, engineering, and computer-controlled programming. Today's industry standard employs Computer Numeric Control (CNC) perforating equipment, which delivers consistent, high-quality results with exceptional accuracy. CNC technology enables operators to design custom perforated panels and efficiently process large volumes while maintaining strict quality control and pattern consistency.

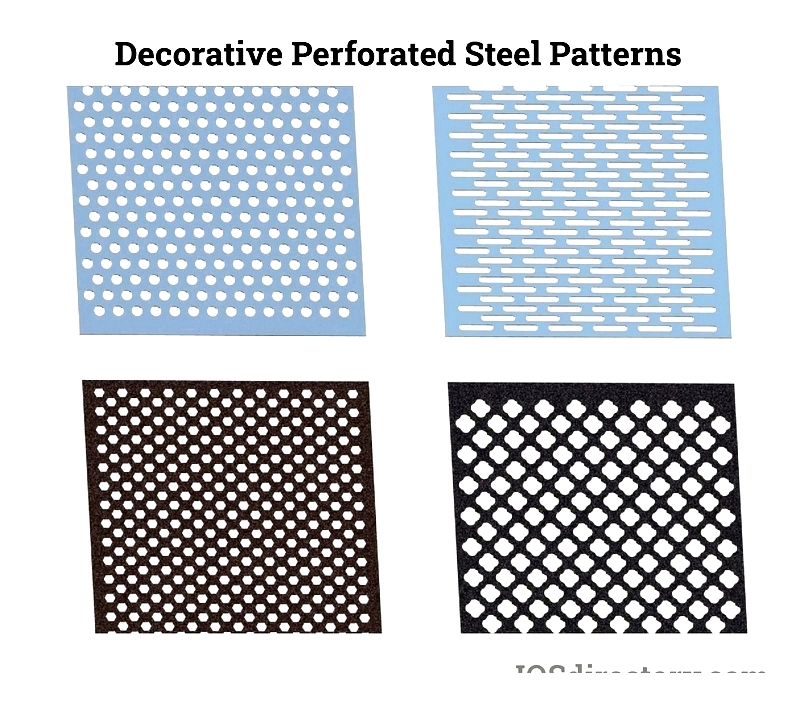

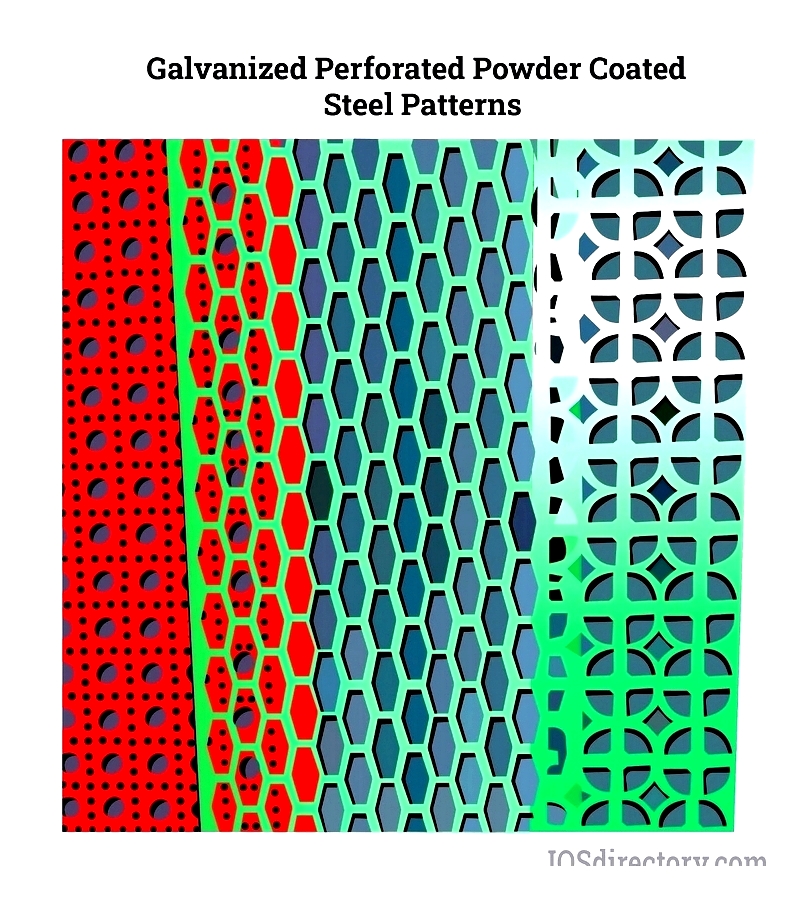

Steel remains the preferred substrate for perforated metal due to its superior tensile strength, ductility, and durability. Material thickness selection varies significantly based on application requirements. Decorative perforated steel typically uses lighter gauges for greater design flexibility, while structural applications like mesh, grilles, safety guards, and handrails require thicker, more resilient materials for load-bearing performance. Manufacturers can select from carbon steel, galvanized steel, or stainless steel grades to meet specific project requirements across industrial, architectural, and commercial applications.

Punch Press Perforation

This fundamental metalworking process shapes perforated steel sheets using mechanical or hydraulic punch presses with specialized tool and die sets. Ultra-hard materials like tungsten carbide or precision-ground tool steel create the punching tools capable of penetrating tough steel substrates. CNC programming aligns the steel sheet between punch and die, with forces ranging from several tons to over 1,000 tons creating each precise perforation. This automated approach offers efficient, cost-effective production for medium to large runs, reducing labor costs and material waste.

Proper press alignment critically affects product consistency and edge quality. Two primary punch press types serve different production needs:

All Across Punch Press – Designed for high-speed, high-volume production, these presses can punch up to 1,600 holes per stroke in materials up to 60 inches wide and 0.002-0.25 inches thick. With punch diameters from 0.024 to 2 inches, they're essential for industrial applications like HVAC grilles and filtration screens, achieving up to 600 strokes per minute.

Section Punch Press – Optimized for thicker steel plates (up to 25 mm), these presses operate sectionally with advanced CNC programming for complex patterns. Ideal for architectural panels and heavy-duty flooring applications.

metal Stamping Perforation

This versatile method produces large quantities of perforated steel components in a single operation. Complex tool and die sets punch, emboss, form, and shear steel plates efficiently, making it ideal for high-volume automotive, appliance, and construction components. The process delivers products meeting strict industry standards for dimensional tolerances and edge quality.

Three principal stamping methods serve manufacturing needs:

Hydraulic metal Stamping – Programmable hydraulic presses deliver controlled force for consistent perforations, especially in large, intricate steel parts. Capable of several thousand tons of force, they match mechanical presses in industrial fabrication.

Mechanical metal Stamping – Flywheel-driven presses transfer kinetic energy rapidly, making them ideal for mass-producing ventilation covers and steel enclosures where speed is paramount.

Mechanical Servo metal Stamping – Servo-driven presses offer programmable stroke control for complex patterns, providing unmatched flexibility despite higher equipment costs.

Selection depends on production volume, pattern complexity, and material specifications, with stamping remaining one of the fastest methods for consistent quality perforated steel.

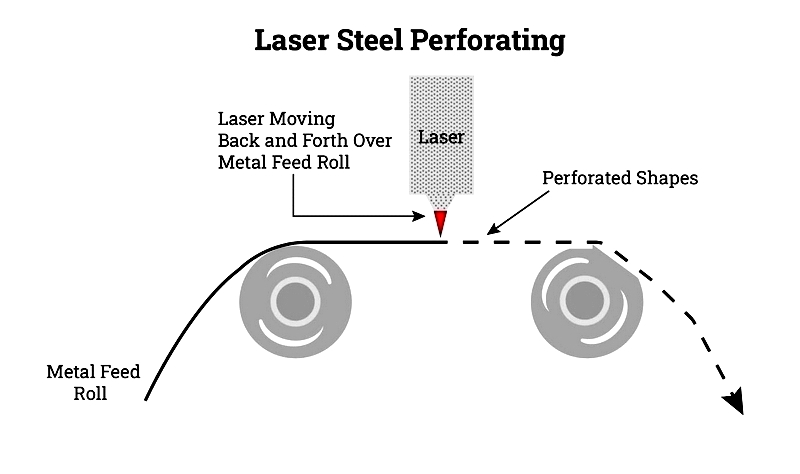

Laser Perforation

Focused laser beams vaporize precise holes in mild, carbon, and stainless steel sheets. This non-contact method produces clean, burr-free edges without distortion. Fiber and CO2 lasers offer exceptional design flexibility for architectural panels and custom grilles, particularly valuable for prototyping and limited runs requiring frequent pattern changes.

CNC-guided lasers achieve tolerances and geometries impossible with mechanical methods. While higher-cost and unsuitable for mass production, laser cutting's precision makes it indispensable for specialized perforated metal fabrication.

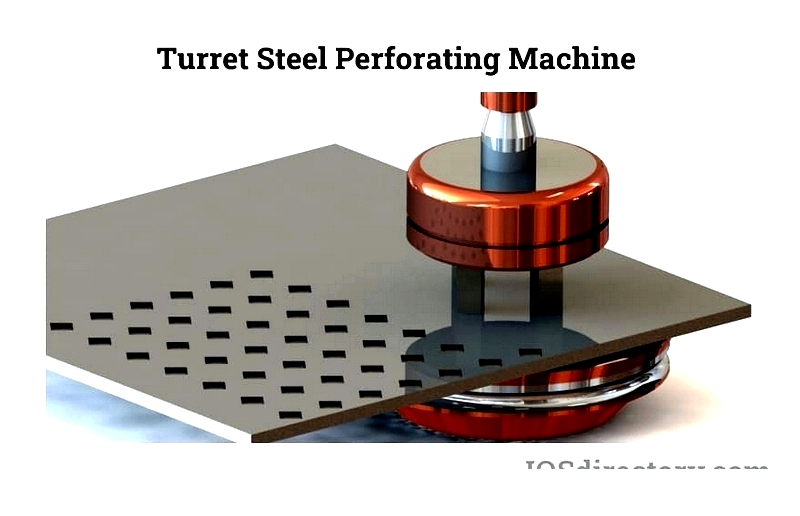

Turret Punching

Turret punching machines feature rotating tool holders for multiple punch shapes, enabling varied hole designs in single cycles. CNC-controlled vertical rams ensure precise alignment and repeatability, reducing setup time and errors. This automated approach excels in high-speed production requiring pattern variety.

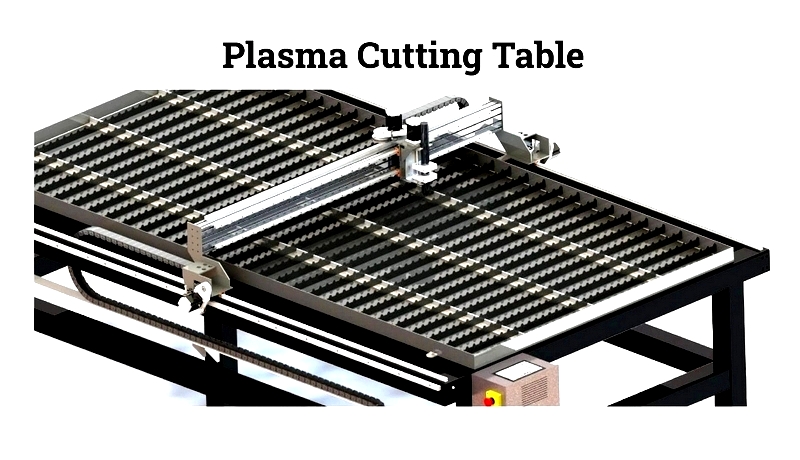

Plasma Cutting

This thermal technique uses ionized gas jets to melt through steel plates, particularly effective for thicker materials. The process creates clean perforations with minimal edge taper, ideal for industrial filters and safety grates requiring rapid turnaround. Gas selection (oxygen, nitrogen, or blends) adjusts to material and quality requirements.

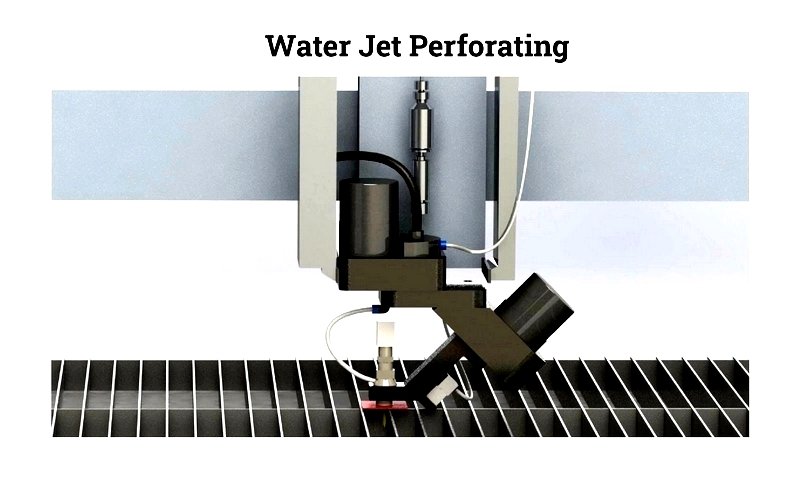

Water Jet Cutting

Ultra-high-pressure water (often with abrasives) cuts through steel of any thickness without heat distortion. This environmentally friendly method suits custom panels and precision components, especially in food, medical, and aerospace applications requiring material integrity.

Water Jet Pump Types

Direct drive pumps offer cost-effective solutions for light-to-medium duty, while hydraulic intensifier pumps handle thicker materials with stable performance. The technology's ability to perform multiple cuts in single passes makes it efficient for complex designs.

Rotary Pin Perforation

High-speed rollers with sharp needles continuously punch small holes in steel sheets or coils. Heated pins can anneal hole edges for enhanced durability. This continuous process excels in producing lightweight perforated metal for filters, diffusers, and automotive components requiring high throughput.

Six-Step Perforation Process

All perforation methods follow these critical stages ensuring quality and consistency:

Impact Phase

Initial punch contact generates compressive force, beginning material deformation before penetration.

Penetration

Punch exceeds material yield strength, creating cavity and determining hole dimensional accuracy.

Fracture

Material reaches tensile strength limit, forming clean break along hole perimeter.