Introduction

This article provides a comprehensive overview of Helical Gears. By reading it, you'll gain insights into various aspects of Helical Gears, such as:

- What Helical Gears are

- Their working mechanism

- Key components

- Selection criteria

- Manufacturing processes

- Different types

- Practical applications

- Pros and cons

- And additional information

Chapter One: Functionality and Selection of Helical Gears

Helical Gears Explained

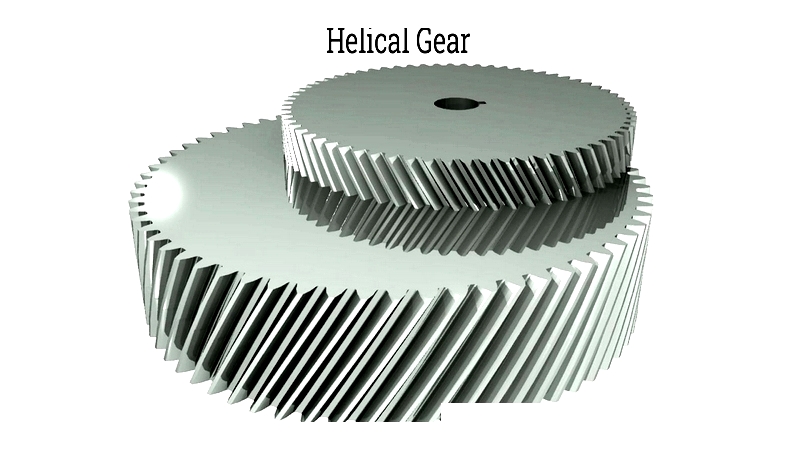

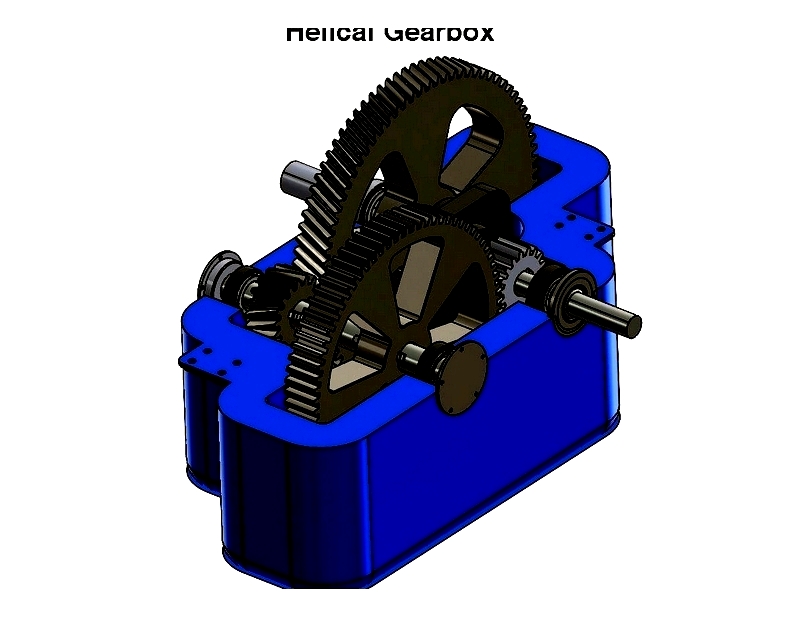

Gears are fundamental mechanical components designed to modify force magnitude or direction. A gear train consists of interconnected gears that transfer power within mechanical systems, playing a crucial role in energy distribution. High-quality helical gears are essential components in industrial gearboxes, which are widely used in mechanical, manufacturing, and construction equipment.

Helical gears primarily increase torque while reducing rotational speed between shafts. They come in two main variants: those for parallel shafts and those for non-parallel shafts. Although similar to spur gears, helical gears are preferred for high-speed applications due to their superior performance characteristics.

These gears feature cylindrical shapes with teeth set at specific angles to the gear axis, known as helix angles. Their design incorporates involute tooth geometry similar to spur gears but offers higher contact ratios, resulting in reduced vibration and noise. With stronger teeth and greater load capacity than spur gears, their modular design ensures high interchangeability in gearboxes, offering engineering advantages and cost-effective production while maintaining component reliability.

Operation of Helical Gears

The key advantage of helical gears lies in their torque ratio, determined by the gear ratio. This ratio compares the speed of the final gear to the initial one in a train, based on energy conservation principles that balance angular velocities and corresponding torques.

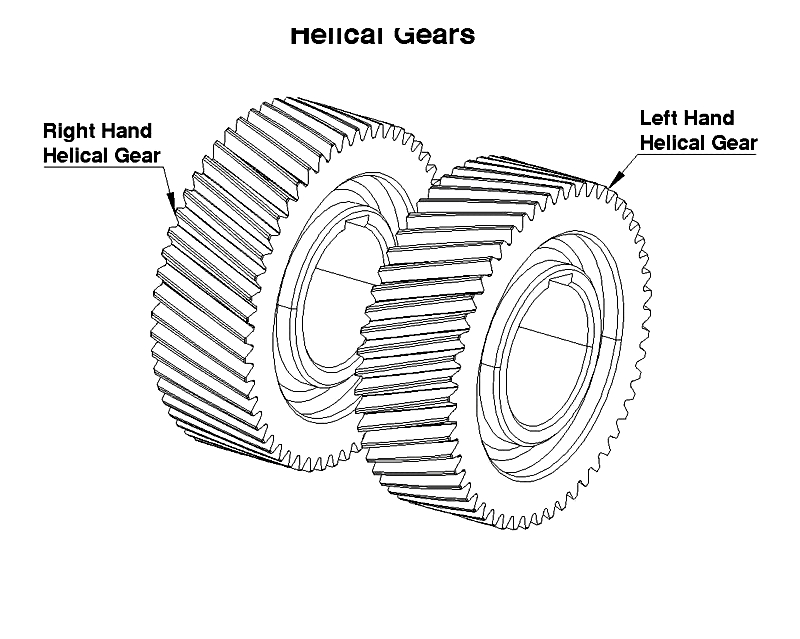

Helical gear teeth are angled relative to the shaft and gear face. During engagement, contact progresses gradually from one end, allowing multiple teeth to share the load and support heavier weights.

This load-sharing and gradual engagement enable smoother, quieter operation compared to spur gears, making them ideal for automotive transmissions. The angled teeth require specific configurations for proper meshing with adjacent gears.

However, the helical tooth design creates sliding contact that generates axial forces and heat, potentially reducing efficiency. These forces necessitate specialized bearings capable of handling both radial and axial loads, typically larger and more expensive than those used with spur gears. The helix angle, usually below 45 degrees, influences these forces - increasing the angle improves speed and motion smoothness but raises axial loads.

Gear Selection Guidelines

When selecting equipment for engineering projects, consider factors like tooth count, pitch diameter, outer diameter, and center distance. Helical gears are often preferred for high-speed applications, significant power transmission, and noise reduction, explaining their prevalence in automotive transmissions.

Chapter Two: Manufacturing Processes for Helical Gears

Key Components of Helical Gears

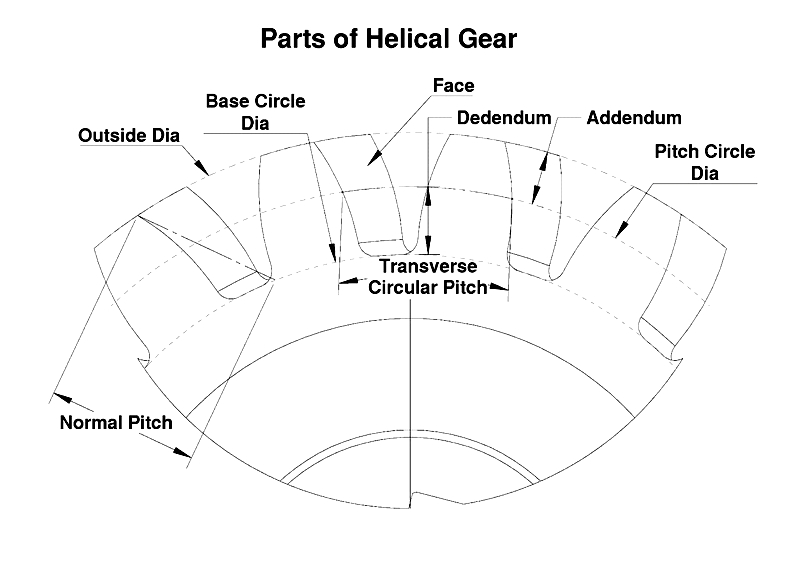

Normal Circular Pitch

The circular pitch (p) measures the distance between corresponding points on adjacent teeth along the pitch circle. Accurate measurement is essential for proper gear meshing and smooth power transmission.

Circular Thickness

Circular thickness (t) refers to the arc length between a gear tooth's sides at the pitch circle, affecting load distribution and gear strength - critical factors in gear design.

Helical Angle

The angle between the involute tooth shape and the transverse plane at the pitch radius, influencing gear engagement, contact ratio, axial thrust, and torque transfer efficiency.

Pitch Diameter

The diameter where pitch is measured, perpendicular to the tooth. Correct pitch diameter is fundamental for compatible gear assembly in industrial and automotive applications.

Helix Direction

Also called Lead, describing the axial advance per rotation. This left-hand or right-hand classification affects axial force direction in parallel shaft systems.

Pitch Circle

An imaginary circle representing effective gear tooth size, used for calculating gear ratios and ensuring consistent tooth geometry.

Circle Pitch Size

The pitch circle diameter (PCD), a reference for determining tooth pitch and corresponding to the friction wheel's outer circumference.

Transverse Pressure Angle

The angle formed by load projection relative to the shaft axis, typically 20° or 25°, affecting gear strength and engagement smoothness.

Centre Distance

The standard or adjusted distance between gear centers, crucial for efficient power transmission and reduced wear.

Addendum (A)

The distance from pitch circle to tooth tip, ensuring proper contact and minimizing undercutting risks.

Outside Diameter

The circumference formed by tooth tips, determining installation space requirements.

Dedendum

The distance from pitch radius to root radius, preventing interference and allowing lubricant flow.

Whole Tooth Depth

The total tooth height from root to tip, affecting strength and load capacity.

Root Diameter

The circle encompassing tooth gap bottoms, supporting reliable operation and minimizing breakage risks.

Contact Ratio

Higher than spur gears due to involute and helical overlap, ensuring smoother power transfer and quieter operation.

Helical Gear Production Methods

Precision gear manufacturing presents significant challenges. The industry has developed various traditional and modern methods to balance cost, quality, and efficiency, considering material selection, quality grade, and production volume.

Selecting appropriate manufacturing techniques is crucial for achieving optimal hardness, finish, strength, and cost-effectiveness in automotive, aerospace, and industrial applications.

Casting Process

Gear blanks are often created through casting, where molten material solidifies in molds. This method suits mass production, especially for large gears where machining is impractical.

Cast blanks work well for applications needing toughness over precision, though additional finishing is typically required.

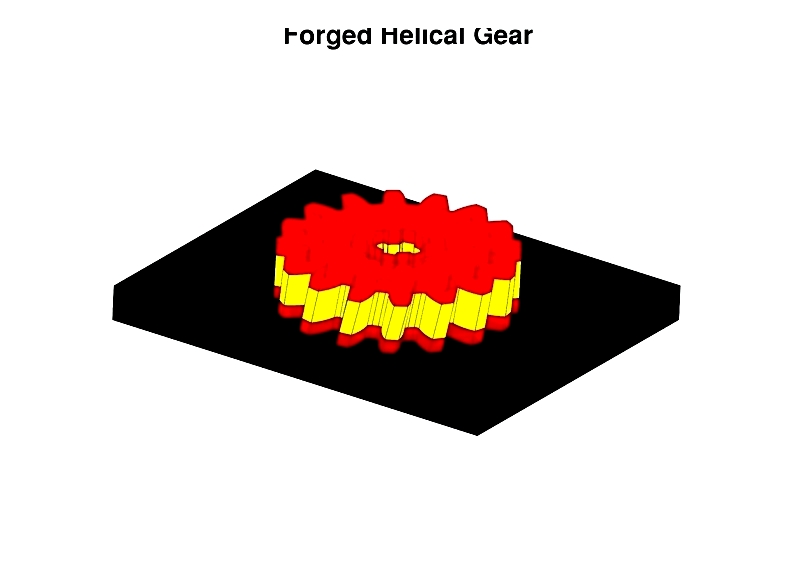

Forging Technique

Forging shapes heated metal through hammering or pressing, producing both blanks and finished gears. While excellent for robust applications, size limitations exist due to required forces.

Forged gears offer superior strength for heavy-duty applications, though heat treatment is essential for fatigue resistance.

Extrusion Method

This process forces material through dies to create shapes, suitable for long gear forms but often requiring additional machining.

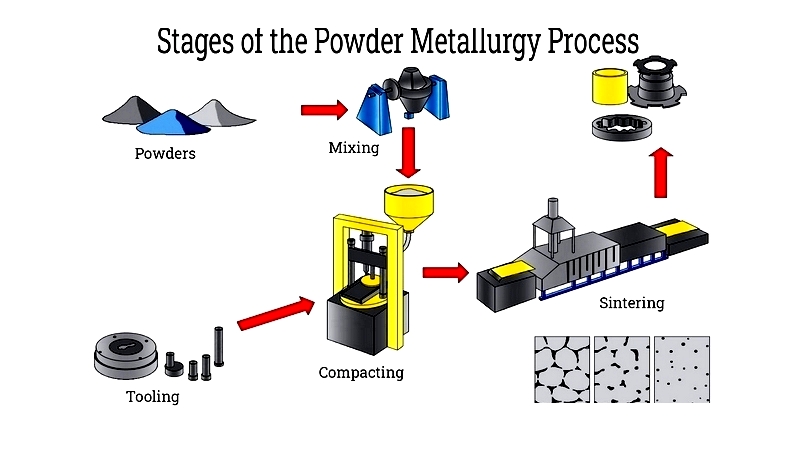

Powder metallurgy

This technique heats compacted metal powders to create components, recently advancing significantly in gear production.

Beginning with metal powder, the process shapes, compacts, and heats the material, offering cost-effective production for small, complex gears without post-processing.

Machining Techniques

Traditional machining has evolved with CNC technology, providing precise control over gear geometry and finish for both prototypes and production.

Common helical gear cutting methods include:

Hobbing

Using a rotating hob against a