Introduction

This article provides a comprehensive examination of power transformers.

Continue reading to explore key topics including:

- Power Transformer Fundamentals

- Working Principles of Power Transformers

- Key Components of Power Transformers

- Different Types of Power Transformers

- Understanding Transformer Losses

- And additional important aspects...

Chapter 1: Understanding Power Transformers

Power transformers are essential electrical devices designed to transfer energy between circuits while maintaining frequency. Operating through electromagnetic induction, they play a critical role in transmitting power from generation sources to distribution networks. These static devices, containing no moving parts, efficiently adjust voltage levels by either increasing or decreasing voltage within alternating current (AC) systems.

Typically operating within voltage ranges of 33 kV to 400 kV with ratings exceeding 200 MVA, power transformers commonly feature standard voltage ratings including 400 kV, 200 kV, 110 kV, 66 kV, and 33 kV. This contrasts with distribution transformers that handle lower voltage ranges from 230 V to 11 kV.

These transformers significantly reduce energy losses caused by Joule's effect during long-distance power transmission. By converting electricity to high voltages for efficient transmission and then stepping it down for safe usage, they become indispensable in power generation facilities, industrial complexes, and utility companies.

Chapter 2: Operating Principles of Power Transformers

Faraday's Law of Electromagnetic Induction

As fundamental components of electrical systems, power transformers rely on Faraday's law of electromagnetic induction to enable safe and efficient energy transfer. This principle explains how alternating voltage in the primary winding generates a time-varying magnetic flux in the iron core, which then induces electromotive force in the secondary winding.

When alternating current (AC) flows through the primary coil, it creates an oscillating magnetic field. The ferromagnetic core provides an optimal path for this flux, ensuring maximum magnetic coupling while reducing energy losses. This process achieves galvanic isolation between circuits while allowing flexible voltage adjustment.

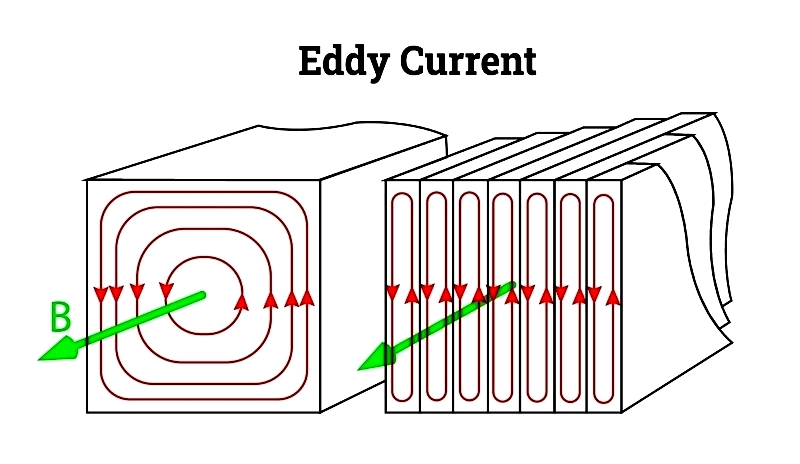

Modern high-efficiency transformers utilize advanced core materials like silicon steel to minimize eddy current and hysteresis losses, enhancing performance in power plants, industrial settings, and renewable energy applications.

Voltage Transformation

Transformers adjust voltage levels according to application requirements, either increasing voltage for transmission or decreasing it for distribution. The output voltage depends on the turns ratio between windings, expressed by the fundamental transformer equation:

Vs = (Vp/Np) × Ns

Where V represents voltage and N indicates winding turns. This ratio determines whether the transformer operates in step-up or step-down configuration, crucial for balancing transmission efficiency with end-user safety requirements.

The power relationship between windings follows the conservation principle:

Vp Ip = Vs Is

This equation demonstrates how transformers maintain nearly constant power transfer (accounting for system losses) while changing voltage and current levels, enabling efficient energy distribution across various applications.

Applications and Technical Considerations

Contemporary power transformers include diverse designs such as distribution transformers, autotransformers, and specialized instrument transformers. Selection criteria encompass voltage ratings, power capacity, cooling methods, and compliance with international standards. Performance evaluation considers factors like load losses, impedance characteristics, and maintenance requirements, all influencing operational reliability and lifecycle costs.

Understanding these operational principles and technical specifications enables informed decision-making when implementing transformer solutions across power generation, industrial, and renewable energy applications.