Introduction

This article provides an in-depth exploration of Air Scrubbers.

You'll discover key information about:

- What an Air Scrubber is

- How Air Scrubbers function

- Different types of Air Scrubbers

- Advantages of using Air Scrubbers

- And much more...

Chapter One - Understanding Air Scrubbers

An air scrubber is an air purification device designed to remove particulate matter from the air through methods like moisture, cooling, or filtration as air passes through the system. Available in two main types - wet and dry - each uses different techniques for particle removal. The primary purpose of an air scrubber is to restore breathable air quality after contamination by toxic substances, chemicals, gases, or other pollutants.

Essential in industrial environments with pollutants or hazardous gases, air scrubbers ensure that air released from facilities is free of contaminants, hazardous emissions, and pollutants. Beyond purification, they also eliminate unpleasant odors and provide fresh, clean air.

Chapter Two - How Air Scrubbers Work

Concerns about indoor and outdoor air quality have grown significantly over the past fifty years, drawing attention from environmental agencies, industries, and homeowners. What was once considered an acceptable industrial byproduct is now recognized as a threat to public health, with pollutants like volatile organic compounds (VOCs), particulates, and chemical fumes linked to respiratory issues and environmental damage. In response, companies and government agencies are establishing and enforcing air quality standards, particularly for industrial pollution control and workplace safety.

One significant advancement is the widespread adoption of air scrubbers. These systems remove contaminants - including dust, allergens, fumes, chemicals, and hazardous substances - from the air. Available in various sizes for both industrial and residential use, they're essential tools for comprehensive air purification.

The air scrubber process uses multiple filtration stages, each targeting specific pollutants. This ensures efficient removal of airborne particles, gaseous contaminants, and microorganisms, typically beginning with specialized filters to capture visible and microscopic pollutants.

Pre-Filter

Large particles can interfere with air filtration systems. Though invisible to the naked eye, these particles range from 2.5 to 100 micrometers. Before air enters the scrubber, a pre-filtration system with HEPA filters removes 99.95% of contaminants. Pre-filters protect larger filters from clogging, maintain airflow, and are especially useful in high-dust environments like construction sites.

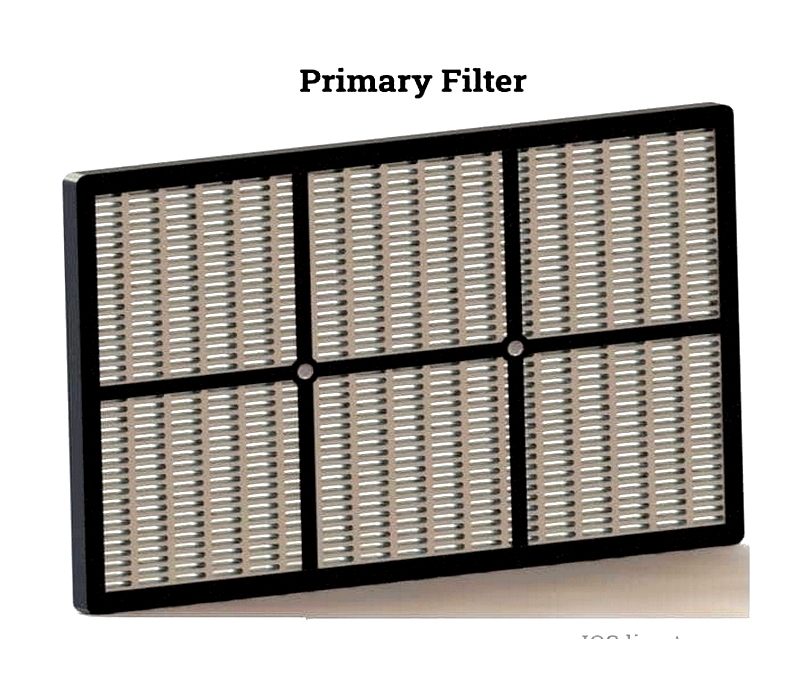

Primary Filter

While pre-filters capture many small particles, some sub-micron particles may pass through. A primary HEPA filter captures particles as small as 0.3 microns, ensuring complete particulate removal. Thicker than pre-filters, these are essential for superior air quality in hospitals, cleanrooms, and food processing facilities.

Carbon Filter

Though not standard, carbon filters are often added for specific applications. They remove gaseous molecules causing odors, particularly useful in industries like waste management. Activated carbon can absorb odors over large areas, making it effective for odor control and chemical vapor reduction.

Carbon Bed Filter

Designed to remove organic contaminants from inorganic streams, these filters use activated carbon in a frame. The carbon, derived from coal, can absorb up to 20% of its weight in impurities. Used in military, pharmaceutical, and food processing applications, they're effective for capturing solvents and chemical vapors.

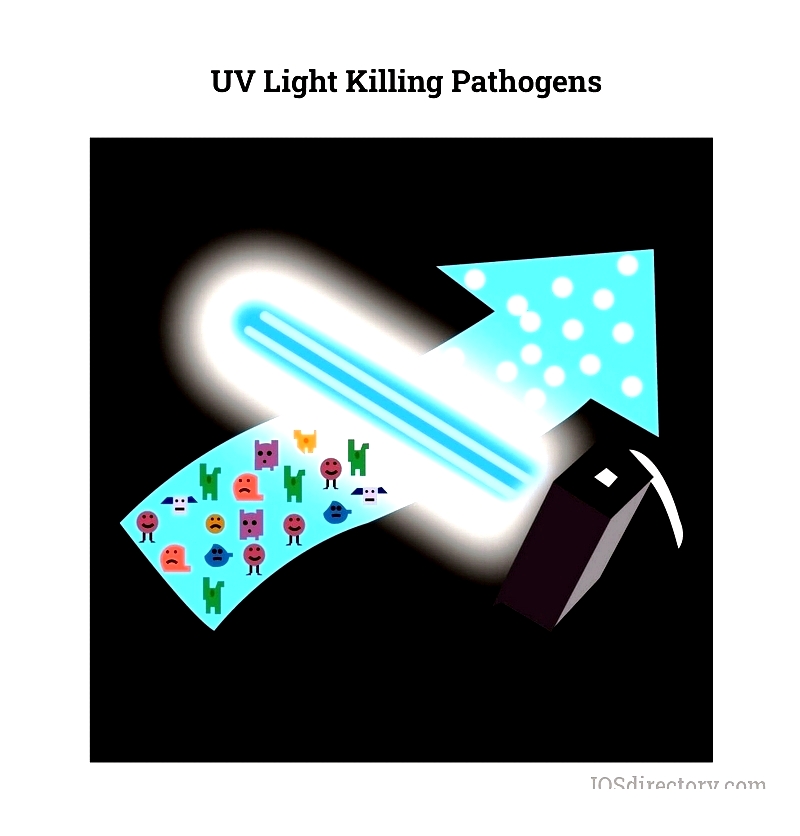

Ultraviolet Light

Some scrubbers include UV lights to inactivate airborne pathogens. UV-C technology disrupts microorganisms' DNA, providing additional protection beyond filtration. Particularly valuable in healthcare settings, it reduces infectious agent spread.

Blower

Essential for system operation, blowers draw air through the filtration system. Some feature variable speeds to optimize performance. Proper airflow control is vital for both portable and industrial units to meet air exchange requirements.

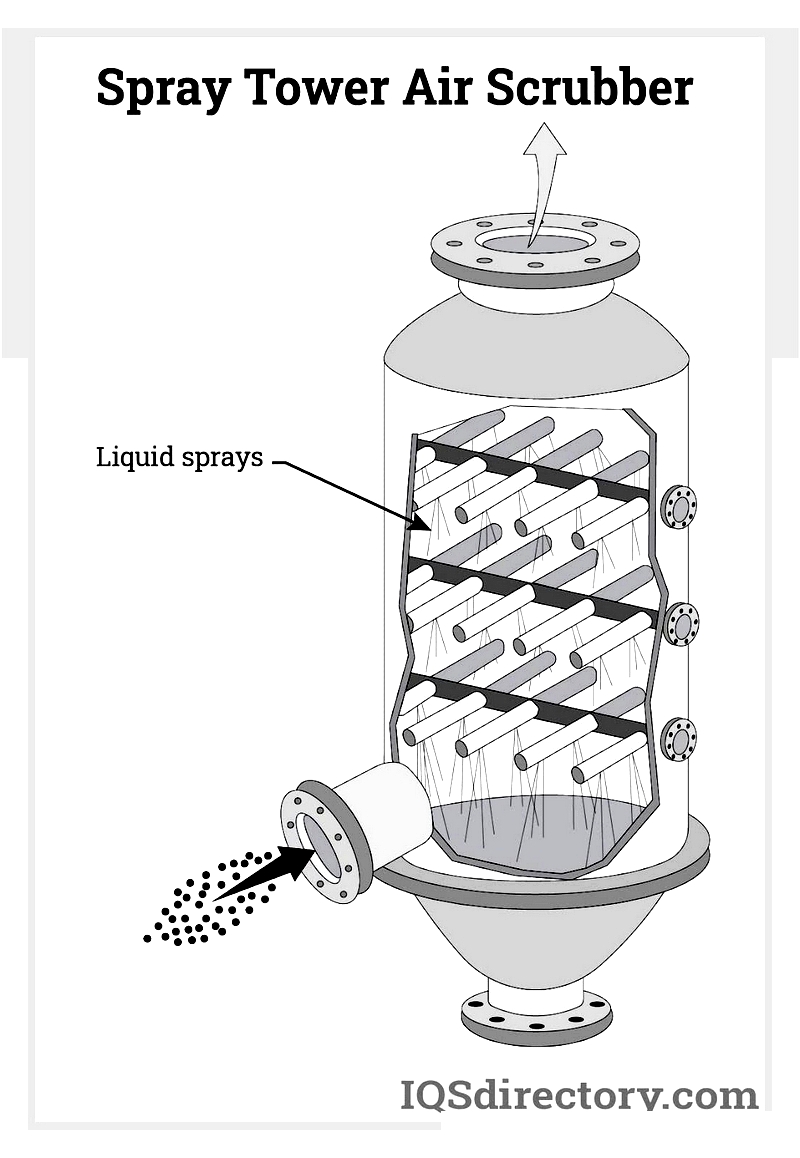

Spray Tower Scrubber

These wet scrubbers treat gas streams with chemical sprays, capturing particles as small as 10 microns. Effective for removing sulfur dioxide, ammonia, and other gases, they're commonly used in chemical processing and waste incineration.

Dry Air Scrubber

Using sprayed reagents, dry scrubbers remove pollutants through chemical reactions. The contaminants are either burned off or collected, making them environmentally friendly. Cost-effective and low-maintenance, they're ideal for steel manufacturing and chemical processing.

Choosing the Right Air Scrubber

Consider pollutant types, air volume, costs, maintenance, and regulations when selecting a system. Industrial applications may require custom solutions, while commercial settings prioritize energy efficiency and noise levels. Reputable manufacturers can recommend appropriate technologies and provide installation guidance.

Chapter Three - Types of Air Scrubbers

Modern air scrubbers target specific contaminants across industries, from pharmaceuticals to energy production. They've evolved to meet stringent air quality standards, handling everything from dust to toxic emissions.

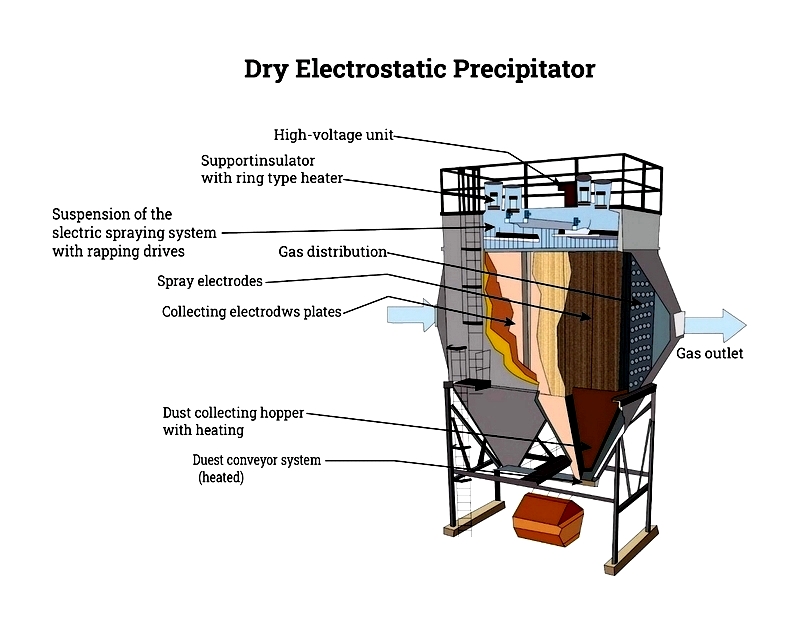

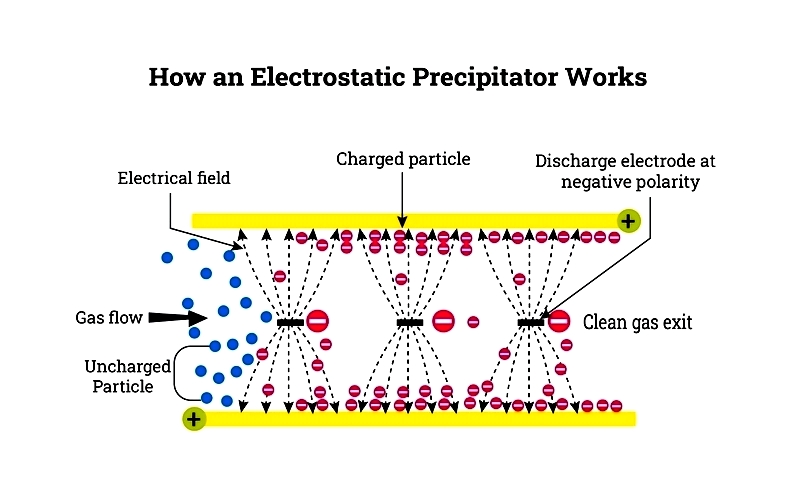

Electrostatic Precipitator

ESPs use electrical charges to remove fine particles from emissions. Common in power plants and cement manufacturing, they're adaptable to various contaminants.

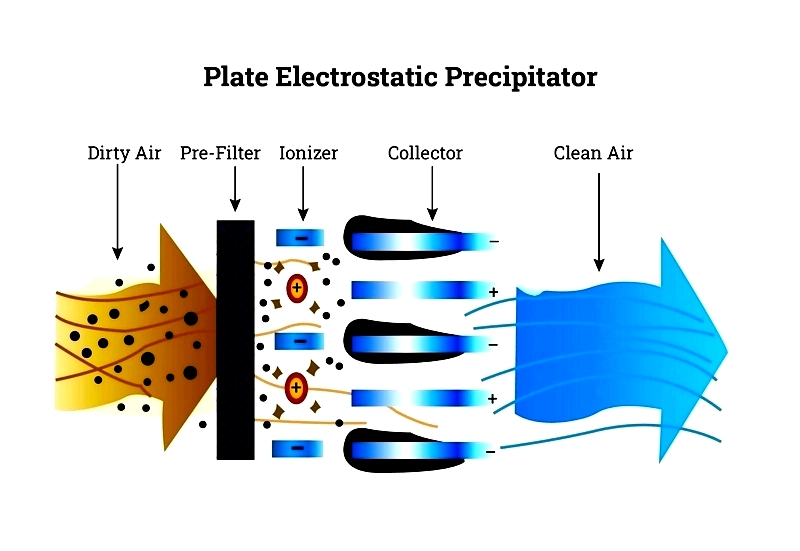

Plate Precipitator

Using wires and collection plates, these ESPs ionize particles for collection. Effective for dust and smoke reduction.

Dry Electrostatic Precipitator

Operating above dew point, these capture dry particulates like ash. Widely used in coal plants, they comply with particulate regulations.