Introduction

This article provides an in-depth examination of gears and their applications.

Key topics covered include:

- What are Gears?

- Gear Design

- Mechanism of Gears

- Types of Gears

- Applications of Gears

Chapter 1: What is a Gear?

A gear is a rotating circular component with teeth designed to transmit torque and adjust speed between shafts, enabling efficient power transfer.

Commonly referred to as cogs, gears feature interlocking teeth that facilitate motion transfer. Operating on lever principles, these mechanical components can modify power direction, speed, and torque. Available in various sizes, gears provide different torque levels and mechanical advantages. The rotational speed and diameter of meshing gears determine velocity. Evenly spaced teeth ensure consistent torque transmission and prevent slippage. Multiple interconnected gears form a transmission system or gear train. A linear toothed strip, called a rack, converts linear motion to rotary motion when engaged with gears.

Gears are classified by shape and shaft alignment. Common shapes include involute, cycloidal, and trochoidal profiles. Shaft configurations may be parallel, intersecting, or non-parallel/non-intersecting. Typically mounted on shafts, the toothed portion remains fixed. Applied force rotates the shaft, driving the gear mechanism. Characterized by radius and tooth count, gears exhibit diverse configurations.

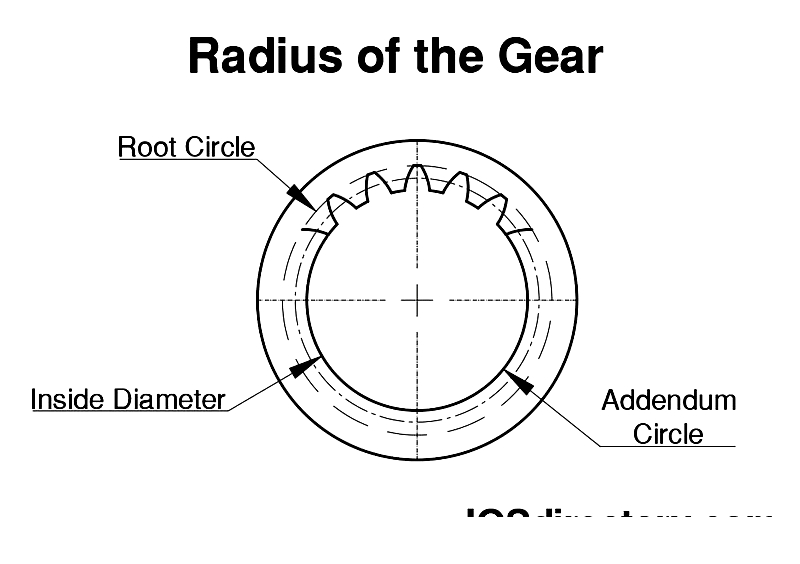

Radius of a Gear

Gear radius varies depending on specific components. Key measurements include root radius and addendum radius. The root radius extends from the gear center to the tooth base, defining the fillet radius where bending stress concentrates. Though challenging to measure, its precision significantly impacts performance. Understanding these measurements is essential for grasping gear geometry and function.

The addendum radius measures tooth extension beyond the pitch circle, spanning from gear center to tooth tip. The addendum circle marks the boundary for external and internal gears. Often equated with pitch radius, it represents the distance from gear center to pitch point.

Gear radius dimensions vary by type. Combined, pitch and addendum radii determine pitch circle diameter.

Gear Teeth

Gear teeth are crucial for engaging other gears and modifying motion. Pitch, the distance between identical points on adjacent teeth, is fundamental to design. Teeth prevent slippage during power transmission. Historically called cogs, their design and placement significantly impact functionality.

Teeth are typically cut into gear blanks but may be individually inserted. Worn teeth often necessitate complete gear replacement. Tooth placement and angle vary by gear type, available as straight or helical configurations. Positioning options include external, internal, or flattened arrangements.

Though seemingly simple, tooth structure requires precise mathematical calculations for accurate design.

Involute teeth, predominant in drive systems, derive shape from base circle diameter. Standard involute teeth mesh with any gear sharing identical pitch, pressure, and helix angles. Contact occurs at single intersection points.

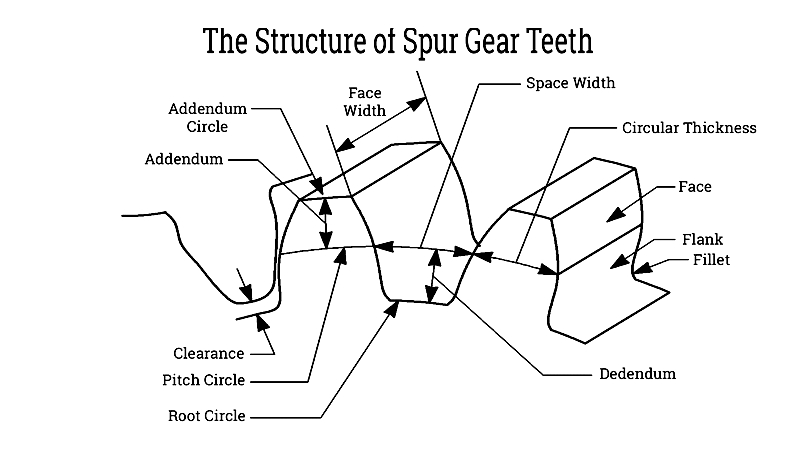

Key tooth design elements include:

- Face of a Tooth: Surface extending beyond pitch surface

- Flank of a Tooth: Surface within pitch surface

- Tooth Thickness: Arc length measurement on pitch circle

- Root Circle: Boundary between teeth

- Tooth Space: Gap between adjacent teeth

- Circular Pitch: Combined tooth and space width

- Diametral Pitch: Teeth count per inch of pitch diameter

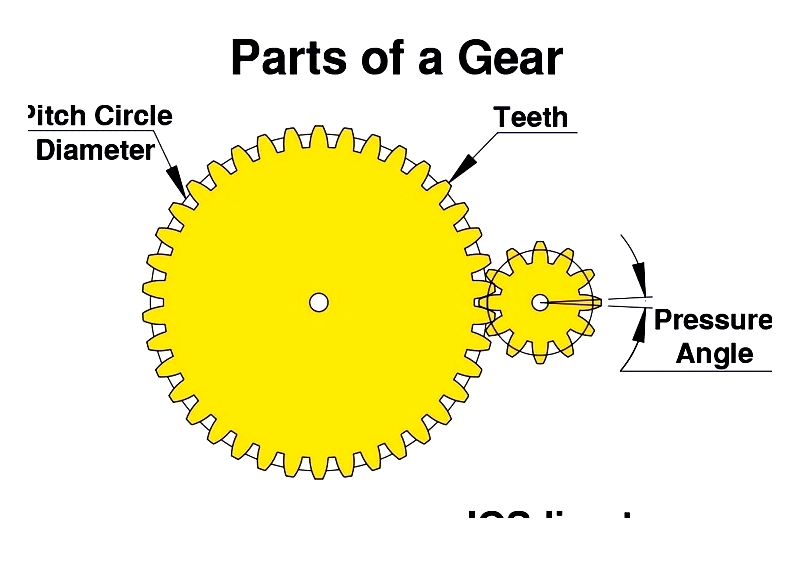

Parts of a Gear

Gears excel in transferring rotational motion and modifying speed, particularly under heavy loads, thanks to precise tooth-shaft control.

Addendum - Tooth extension beyond pitch circle (external gears) or inward (internal gears). The addendum circle defines this boundary.

Axis - Determines movement direction and transmission. Common configurations include parallel, intersecting, and non-parallel/non-intersecting axes.

base Circle - Theoretical construct for generating involute tooth profiles.

Circular Pitch - Distance between corresponding points on adjacent teeth, measured along pitch circle.

The module simplifies tooth size calculations, using rational numbers instead of π.

Dedendum - Tooth portion below pitch circle extending to minor diameter.

Diametral Pitch (DP) - Teeth count relative to pitch diameter, ensuring meshing compatibility. Higher values indicate smaller teeth.

Fillet - Curved transition at tooth base.

Form Diameter - Imaginary circle connecting fillet curves.

Gear Ratio - Speed comparison between meshing gears.

Pitch Circle - Critical dimension for proper gear interfacing.

Pitch Diameter - Defines pitch circle dimensions for spacing calculations.

Pressure Angle - Tangent angle at pitch circle, typically 14.5°, 20°, or 25°.

Teeth - Projecting elements that transmit rotation, available in external or internal configurations.

Parts of Gear Teeth

Tooth profile shapes gear functionality, with involute curves being most common. Specialized profiles include cycloidal and trochoidal forms, all critical for efficient power transmission.

The tooth profile spans from outer to root circle in cross-section.

Top Land - Flat surface at tooth tip, indicating face width.

Tooth Thickness - Distance between opposing faces along pitch circles.

Tooth Face - Protruding surface beyond pitch circle.

Tooth Flank - Surface extending from tip to root.

Fillet Radius - Curved transition at tooth base where stress concentrates.

Tooth Pitch - Measurement between adjacent tooth points.

Pitch Point - Tangency point influencing gear velocity ratios.

Face Width - Axial tooth dimension enhancing strength.

How Gears Work

Circular mechanical components with interlocking teeth transmit rotational force and torque. Paired gears prevent slippage through meshing. Circular gears maintain constant speed ratios, while non-circular variants enable variable ratios. Profile shaping ensures consistent performance. Smaller driver gears (pinions) increase torque while reducing speed, and vice versa. Proper shaft alignment - parallel, non-parallel, intersecting, or non-intersecting - is essential. Gear systems produce three primary outcomes:

-

Increase Speed

Example: A 20-tooth gear driving a 40-tooth gear doubles speed while reducing force.

-

Increase Force

More teeth on driver gear decreases speed, requiring greater force.

-

Change Direction

Meshing gears rotate in opposite directions, with specialized gears enabling complex directional changes.