Introduction

This article provides an in-depth exploration of bulk bag handling equipment.

It covers key topics including:

- Principles of Bulk Bag Handling Equipment

- Material Handling Equipment

- Types of Bulk Bag Handling Equipment

- Applications and Benefits of Bulk Bag Handling Equipment

- And More...

Chapter 1: Principles of Bulk Bag Handling Equipment

This chapter examines the different types of equipment used for efficient bulk bag management.

Understanding Bulk Bag Handling Equipment

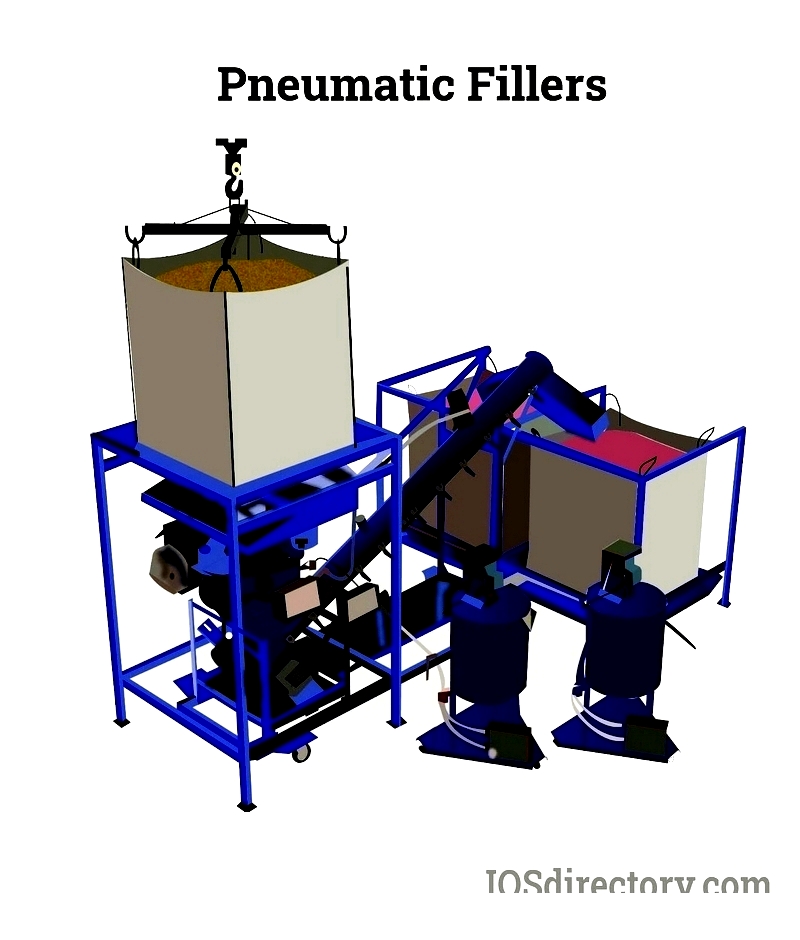

Bulk bag handling equipment consists of specialized devices designed for storing and transporting bulk bags. These machines are typically used at production start points to transfer materials into pneumatic conveyors, which then package and palletize them for shipping.

Industrial bulk bags, made from durable fabric, store and transport dry, free-flowing materials like sand, grains, fertilizers, and plastic granules. They play a vital role in various applications, particularly in pneumatic conveying systems.

These handling systems are employed across diverse settings, including greenhouses, manufacturing plants, commercial farms, food distribution centers, pharmaceutical facilities, and more.

Chapter 2: Material Handling Equipment

Material handling equipment enhances efficiency, productivity, and safety in supply chain and industrial operations. These solutions are categorized by function and placement within manufacturing, warehousing, and distribution environments. Key categories include transportation, storage, load formation, placement, and retrieval. Modern automated facilities often integrate warehouse management systems (WMS), inventory control, and smart automation with physical equipment. These integrated systems enable real-time tracking, asset management, and streamlined workflows, supporting lean manufacturing and just-in-time (JIT) inventory practices.

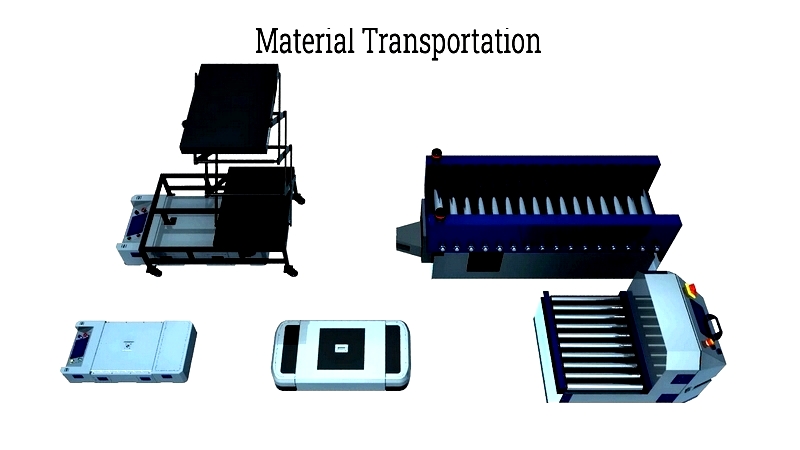

Material Transportation

In materials management, "transportation" refers to moving raw materials, components, and products using specialized tools. This includes overhead cranes, electric hoists, automated guided vehicles (AGVs), conveyor systems, and belt conveyors that transport inventory within warehouses or production facilities. Equipment like hoists, cranes, and roller conveyors optimizes movement between workstations, production lines, and fulfillment zones, reducing manual labor and product damage.

Forklifts, dollies, hand trucks, and pallet jacks are essential for loading/unloading pallets and moving heavy goods. The speed and accuracy of material delivery directly impact production quality, cycle times, and throughput. Selecting appropriate handling equipment ensures operational efficiency and supply chain reliability.

Transport methods depend on product size, shape, weight, and destination. Modern production lines use cobots, robotic palletizers, sorting systems, and smart feeders. These automated systems improve throughput, accuracy, and safety while integrating with enterprise resource planning (ERP) software for precise tracking.

Shipping and Receiving Equipment

Shipping and receiving departments are crucial for inbound/outbound logistics, where efficient product management affects lead times and order fulfillment. Key equipment includes side-loaders, pallet trucks, walkie stackers, order pickers, and inventory locators. Platform vehicles like dollies and hand trucks enable ergonomic handling of various loads. Mobile roller conveyors and telescopic belt conveyors adapt to different shipping scenarios for truck loading and dock operations.

Modern operations may use barcode scanners, RFID tracking, and automated sorting to enhance inventory visibility. Integrated shipping software synchronizes inventory management, improves traceability, and reduces labor costs in competitive logistics sectors.

Special Material Handling Operations

Specialized handling equipment transports, stores, and processes bulk materials in mining, agriculture, food processing, construction, and chemical industries. This includes stackers, storage hoppers, grain elevators, belt/screw conveyors, pneumatic systems, and rotary dumpers. Equipment selection depends on material characteristics, volume, and safety requirements.

Modern facilities integrate automation and dust containment solutions with bulk handling systems, reducing contaminants and improving safety. Digital sensors and controls enable continuous monitoring and optimized throughput.

Warehousing, Material Placement, and Retrieval

Warehousing is critical for raw material storage and finished goods staging. Effective operations involve systematic organization, categorization, and retrieval to meet customer demand. Materials are stored in shelving, racking systems, bins, and cabinets with clear labeling and barcode scanning for efficient picking.

Many warehouses use automated storage and retrieval systems (ASRS), vertical lift modules (VLMs), and carousels to maximize storage density. These solutions employ robotics and conveyors for precise inventory movement, improving picking accuracy and reducing labor costs. Inventory control software and warehouse execution systems (WES) enhance traceability.

Retrieval is streamlined with forklifts, reach trucks, pallet jacks, and automated carts. Warehouse Management Systems (WMS) and supply chain analytics provide insights into inventory turnover and space utilization, supporting smarter decisions.

Advanced material handling combines lean practices, automation, and data-driven optimization to ensure accurate, cost-effective asset movement throughout the supply chain, enhancing customer satisfaction and competitive advantage.