Introduction

This article provides an in-depth exploration of centrifugal blowers.

You will learn about:

- What centrifugal blowers are

- The different types of centrifugal blowers

- Applications of centrifugal blowers

- How centrifugal blowers operate

- And more...

Chapter One - What is a Centrifugal Blower?

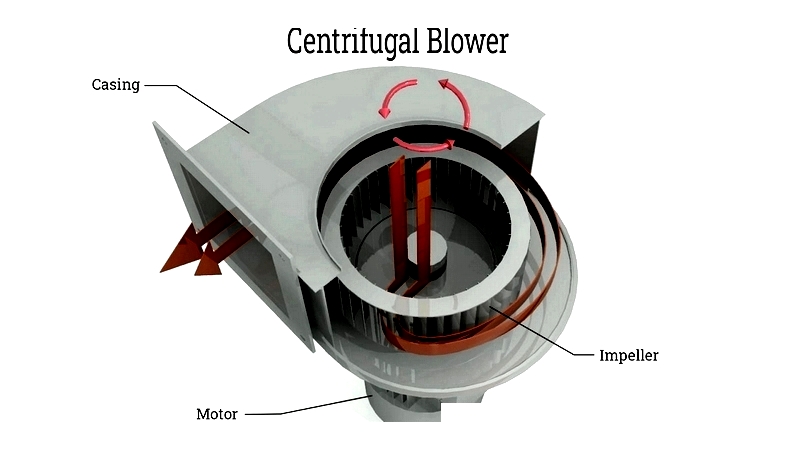

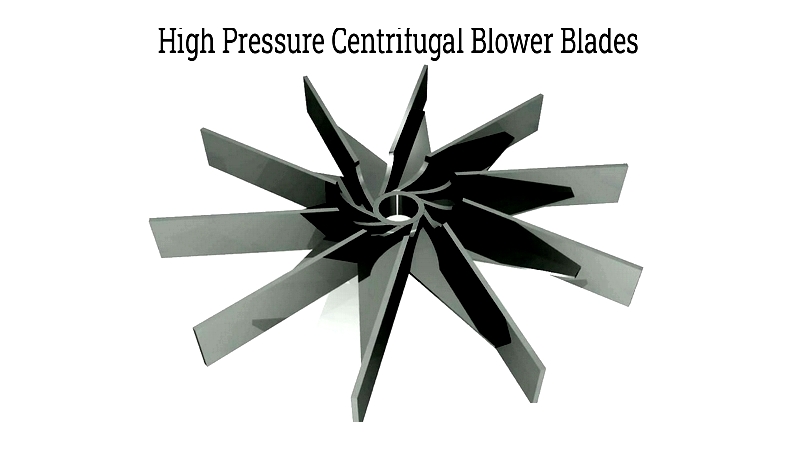

A centrifugal blower is a mechanical device that moves air using centrifugal force generated by a rotating impeller. The impeller draws in air or fluids and discharges them through an outlet. Key components include the impeller, housing, and drive mechanism. The impeller features blades mounted on a central hub connected to a fan shaft, which is crucial for its operation.

The drive mechanism, whether belt-driven or direct-driven, determines the impeller's rotational speed. Known for their high speed and efficiency, centrifugal blowers are versatile machines used in various industries, including drying processes and HVAC systems.

Blade design significantly affects a centrifugal blower's performance and efficiency by influencing air movement through the system. Common blade configurations include forward curved, backward curved, and radial designs.

Chapter Two - Types of Centrifugal Blowers

In industrial ventilation and HVAC systems, the terms centrifugal blower and fan are often interchangeable. However, "blower" specifically distinguishes these high-performance devices from axial fans, which move air linearly along the rotation axis. Centrifugal blowers use a radial path to create high-pressure airflow for demanding applications.

The main difference among industrial centrifugal blowers lies in their impeller blade geometry, which affects performance factors like pressure, velocity, and efficiency. Impellers may be backward curved, forward curved, or radial, each suited for specific operating conditions, air volumes, and system resistance.

Centrifugal blowers are crucial in air handling units, dust collection systems, pneumatic conveying, and pollution control. Their design ensures consistent airflow even with variable system pressures or duct obstructions. Unlike axial fans, they effectively build static pressure, making them essential for spray booths, fume extraction, and industrial drying.

While no universal classification exists, industry experts typically categorize centrifugal blowers into six or more types based on impeller design and application. Each type has unique features, advantages, and limitations that affect selection for commercial and industrial uses. Choosing the right centrifugal blower is vital for process reliability, energy efficiency, and equipment longevity.

Forward Curved Centrifugal Blowers

Forward curved centrifugal blowers have blades that curve in the direction of rotation. Their short, curved blades produce high static pressure and significant airflow (CFM), though less efficiently than other designs. Often called squirrel cage blowers, they're commonly used in low-pressure, high-volume applications like residential HVAC furnace blowers, small air handlers, cleanrooms, and ventilation units.

Their compact size and quiet operation make forward curved blowers ideal for indoor environmental control. Typical components include an impeller, shaft, bearings, and scroll housing that directs airflow into ducts. While they generate higher pressure peaks, these industrial blowers have lower mechanical efficiency and are best when noise and space are priorities over power consumption.

Backward Inclined Centrifugal Blowers

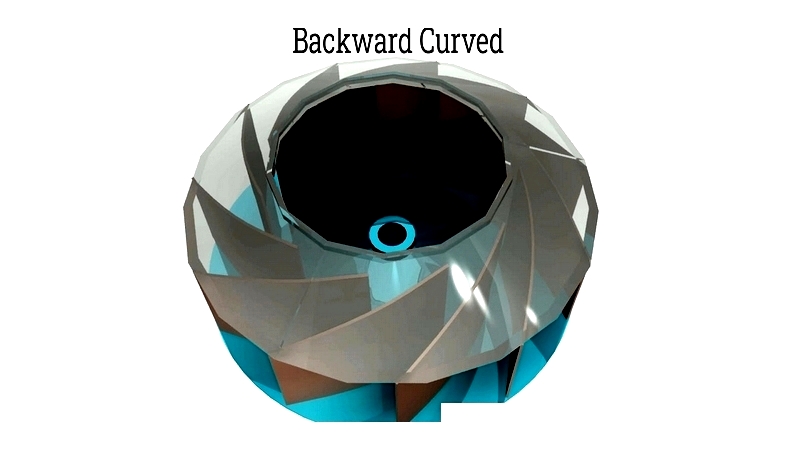

Backward inclined centrifugal fans feature blades that tilt away from the rotation direction, with three main styles: flat single thickness, curved single thickness, and curved airfoil. Their aerodynamically optimized design offers higher efficiency, lower noise, and reduced energy consumption compared to forward curved models.

Widely used in industrial exhaust, process ventilation, and dust collection, backward inclined blowers excel in medium to high static pressure applications. Their robust construction and geometry allow efficient operation across various airflow rates, making them ideal for fume extraction, paint booth exhaust, and process cooling.

Curved Single Thickness Blade

Curved single thickness blades provide strength and abrasion resistance for air streams with particulates or corrosive gases. Premium models feature wear-resistant liners and high-temperature coatings for harsh environments like chemical processing. Their ability to withstand high temperatures and aggressive contaminants makes them valuable in heavy industry.

Flat Single Thickness Blades

Flat single thickness blades emphasize durability and cost-effectiveness. While less efficient than curved designs, these blowers excel where ruggedness and easy maintenance are priorities, such as foundry ventilation and abrasive dust streams. Protective liners can enhance service life and reliability in harsh conditions.

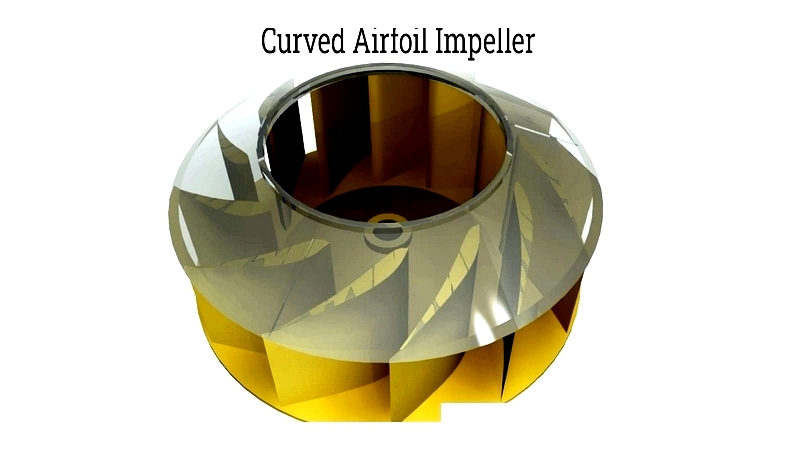

Curved Airfoil

Curved airfoil centrifugal blowers use advanced wing-like blade shapes for maximum efficiency. Ideal for high-volume, low-pressure applications where energy conservation matters, like office HVAC, laboratory exhaust, and commercial building systems. Their aerodynamic design reduces turbulence, noise, and particulate buildup, improving efficiency and lowering maintenance needs.

Radial Centrifugal Blowers

Radial centrifugal blowers have blades extending straight outward from the hub, perpendicular to rotation. This simple design prevents dust and debris accumulation, minimizing clogs. Rugged and reliable, they're ideal for dust collection, pneumatic conveying, baghouse exhaust, and grain handling where conveying reliability is critical.

Some models feature reinforced side rims for abrasive or moist environments. While offering medium to high static pressure and good airflow, radial blowers are easy to clean and maintain, making them indispensable in woodworking, concrete production, and conveying systems.

Airfoil Centrifugal Blowers

Airfoil centrifugal blowers are designed for energy efficiency, quiet operation, and clean air movement. Their blades combine rounded leading edges with tapered trailing edges for minimal turbulence and superior aerodynamics. These blowers are ideal for hospital ventilation, cleanrooms, data center cooling, and other critical air quality applications requiring low noise and efficient airflow.

Airfoil blowers deliver large volumes of filtered air with lower power input and support variable speed drives (VFDs) for optimal control. Their high efficiency reduces energy costs and supports sustainable building requirements.

Radial Tip Centrifugal Blowers

Radial tip centrifugal blowers combine radial blower durability with backward inclined efficiency. Their specially tipped blades handle varied airflows and pressures, including contaminated or abrasive streams. This hybrid design makes them ideal for pneumatic conveying, grain drying, combustion air supply, and handling moist or hot gases.

Most are made from corrosion-resistant materials like stainless steel with epoxy or ceramic coatings for durability. Heavy-duty linings extend service life and reduce downtime in harsh industrial environments.