Introduction

This article covers everything you should know about Mezzanine Floors.

You'll explore topics including:

- What is a Mezzanine Floor?

- Types of Mezzanine Floors

- Mezzanine Floor design

- Uses for Mezzanine Floors

- And much more...

Chapter One: What is a Mezzanine Floor?

A mezzanine floor is an intermediate platform between the main floor and ceiling, designed to maximize vertical space for storage, assembly tasks, or office use. Typically occupying up to 25% of a building's floor area, it's carefully planned and installed to meet specific needs efficiently.

While primarily used for additional storage, mezzanine floors also support manufacturing, distribution, office spaces, and retail areas. By utilizing vertical space, they provide cost-effective additional square footage with minimal investment.

Chapter Two: Types of Mezzanine Floors

Mezzanine flooring systems maximize unused overhead space in industrial, commercial, and warehouse settings. They increase storage capacity, optimize workflow, and improve efficiency without costly expansions. Custom mezzanine platforms offer flexible installation, adapting to various layouts, structures, and load requirements. Their modular construction and custom engineering allow optimal dimensions and functionality for production, storage, office, or retail use.

A mezzanine's safety and effectiveness depend on its flooring material. The right choice ensures strength, compliance, and suitability for pallet storage, conveyors, or workspaces. Professionals consider environmental factors, building codes, fire regulations, and material handling equipment when recommending mezzanine decking solutions.

Bar Grating

Bar grating offers exceptional strength and durability for high-traffic industrial settings. Its open grid allows light and air circulation while enhancing sprinkler system effectiveness. Made from aluminum, carbon steel, or stainless steel, it provides slip resistance and requires minimal maintenance.

Wood Mezzanine Flooring

Wood flooring combines aesthetic appeal with easy installation and durability. Ideal for offices and retail spaces, it supports shelving and light equipment while offering a warm, inviting appearance. Its cost-effectiveness and easy maintenance make it popular for light-use areas.

Steel Diamond Plate Mezzanine Flooring

Steel diamond plate delivers superior safety and load capacity for industrial use. Its textured surface prevents slips, supporting heavy equipment and inventory. Typically made from 12-gauge steel, it's ideal for manufacturing plants and high-traffic areas.

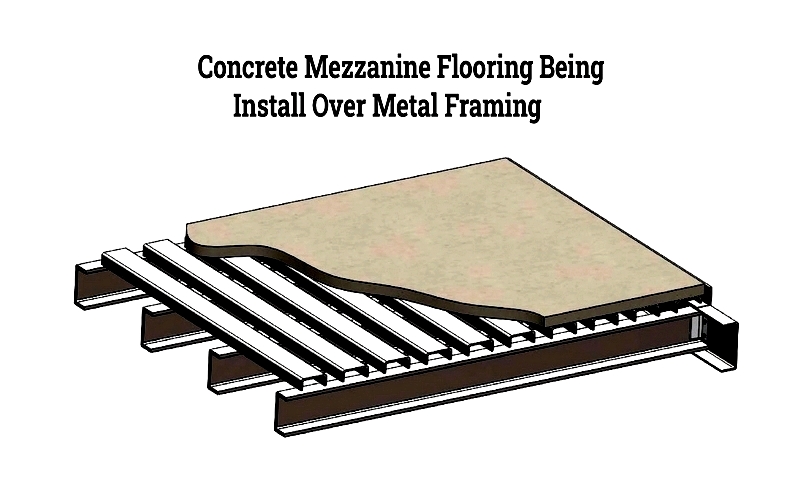

Concrete Mezzanine Flooring

Concrete flooring provides unmatched durability for permanent installations. Suitable for warehouses and processing plants, it resists fire and moisture while supporting heavy equipment. Its thermal mass improves energy efficiency.

For permanent expansions requiring strict compliance, concrete offers reliable, long-term solutions.

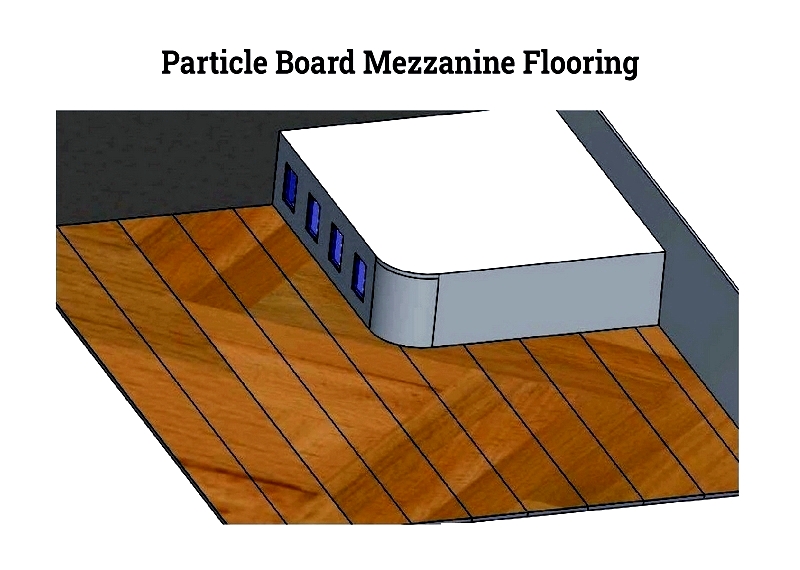

Particle Board Mezzanine Flooring

Particle board offers an affordable option for light-duty applications. With moisture-resistant surfaces, it suits offices and retail spaces but isn't recommended for wet or heavy industrial environments.

Laminated Panel Mezzanine Flooring

Laminated panels combine durability with chemical resistance, making them ideal for manufacturing and food processing. Their non-slip surfaces enhance safety in wet conditions.

Resin Composite Mezzanine Flooring

Resin composite excels in demanding environments, offering impact resistance and hygiene. Perfect for pharmaceutical and food facilities, it withstands moisture and temperature variations.

Choosing the Right Mezzanine Flooring

Consider load requirements, safety compliance, equipment traffic, and environmental factors when selecting flooring. Professional consultation ensures the best solution for your specific needs and budget.