Introduction

This article explores various aspects of burn barrels and their usage.

You will learn about:

- What a Burn Barrel is

- Different Types of Burn Barrels

- How Burn Barrels are Constructed

- Safety Standards for Burn Barrels

- And much more...

Chapter One - Understanding Burn Barrels

A burn barrel is essentially a repurposed metal drum designed for safely incinerating combustible waste. These containers provide an effective waste disposal method while helping reduce landfill accumulation.

Traditionally used in rural areas lacking trash collection services, burn barrels have become increasingly regulated. They're now more commonly found in populated areas that follow strict operational guidelines.

In remote locations, traditional waste disposal methods like open burning were once standard. With growing environmental awareness, these practices are now recognized as ecologically harmful. Burn barrels offer a safer, more environmentally conscious alternative that meets modern standards.

Typically constructed from modified 55-gallon drums, burn barrels contain materials for controlled burning. While smaller drums can be used, they require more frequent monitoring and pose greater safety risks from escaping embers.

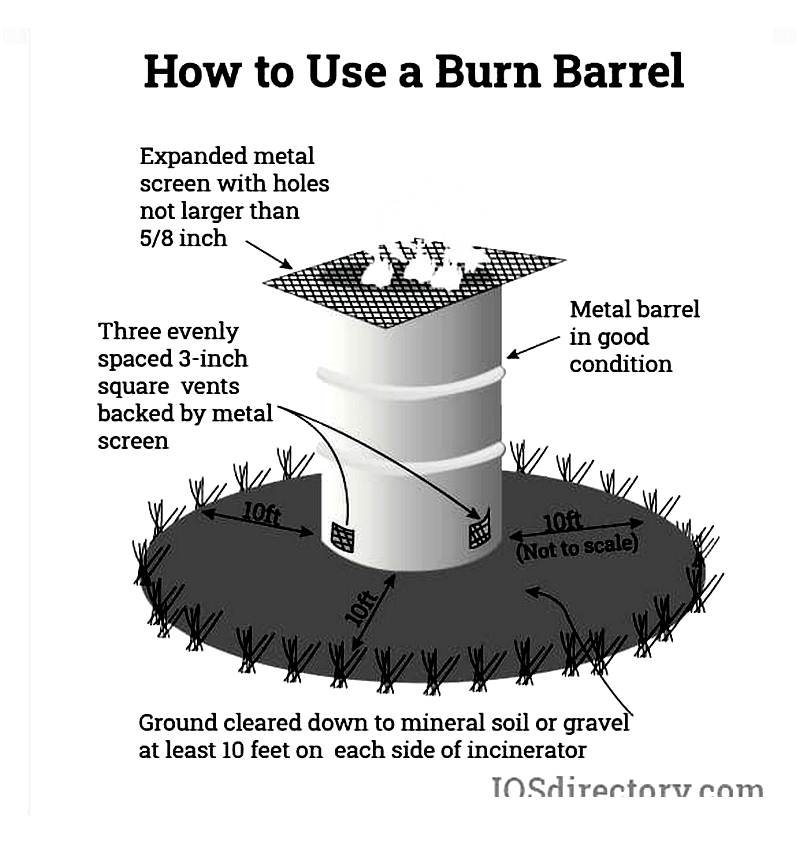

When used properly, burn barrels provide a safe and efficient way to dispose of combustible materials while protecting users and the environment.

Historically, open burning was the primary method for waste disposal. With increasing environmental regulations, most areas now restrict open burning. In the U.S., specific state and county regulations govern waste burning, often requiring simple permits obtained through local officials.

Chapter Two – Types of Burn Barrels

While burn barrels may seem simple, choosing the right type and using it properly is crucial for safety and efficiency. Commonly used in rural areas for burning trash and yard waste, improper use can lead to pollution or wildfires. Understanding available options, regulations, and best practices ensures safe operation and environmental compliance.

Originally made from 55-gallon drums, burn barrels now come in various specialized designs. These innovations address fire safety, emissions control, and ease of use while meeting local regulations. This variety helps users select the most suitable barrel for their specific waste disposal needs.

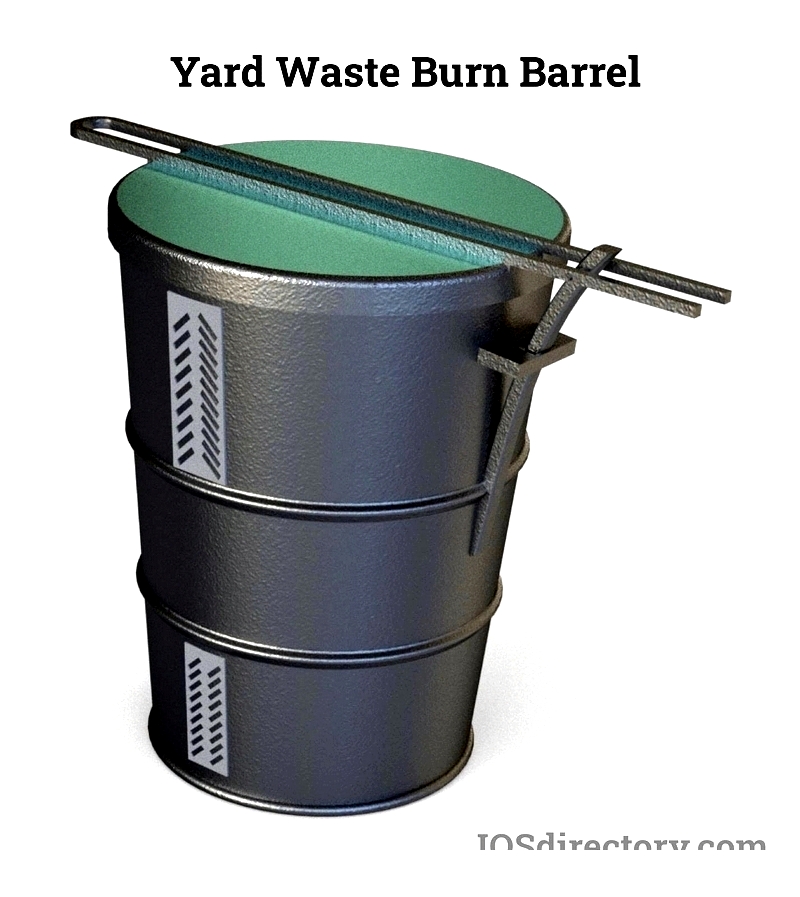

Yard Waste Burn Barrels

Yard waste burn barrels provide a practical solution for burning leaves, branches, and untreated wood. Since open burning is often restricted, covered barrels help contain ash and embers while reducing fire risks.

Always check local regulations before burning yard waste. Avoid burning treated wood or toxic plants, and ensure materials are dry for efficient combustion. Cut debris into manageable pieces and prepare the surrounding area by removing flammable materials.

After burning, cool ashes completely and dispose of them properly to prevent environmental contamination.

Galvanized Garden Incinerators

These compact incinerators, made from zinc-coated metal, are ideal for urban areas with space limitations. Look for EPA-compliant models with features like spark arrestors and easy ash removal for safer operation.

The galvanized coating provides corrosion resistance but shouldn't be overheated to avoid toxic fumes. Choose models designed specifically for high-temperature use.

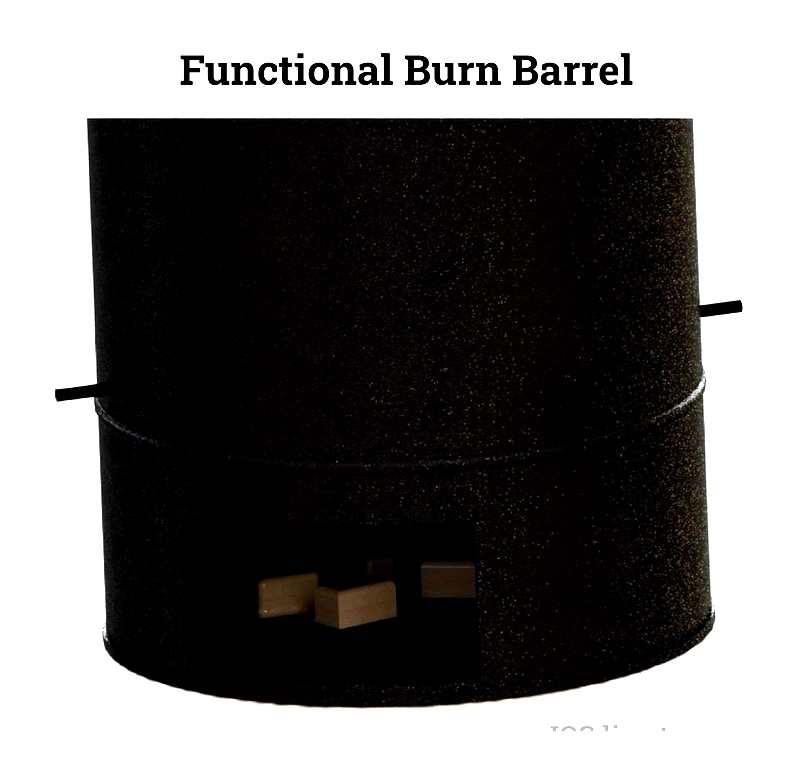

Functional Burn Barrels

These barrels feature design elements that optimize safety and efficiency:

- Easy-access ignition points

- Ventilation for better combustion

- Stable containment for various materials

Many commercial models include removable ash pans for easy cleaning and compliance with environmental standards.

20 Gallon Trash Can Burn Barrels

These smaller barrels are ideal for residential use with limited space. Look for models with heat-resistant coatings, ventilation holes, and secure lids designed specifically for burning.

Their portable size makes them convenient for occasional use and easy storage.

Stainless Steel High-Temperature Burn Barrels

These durable barrels withstand extreme temperatures (up to 1600°F) while providing complete combustion with minimal smoke. Their vented designs and secure lids make them ideal for sensitive material disposal.

The stainless steel construction ensures longevity with minimal maintenance, suitable for both residential and commercial use.

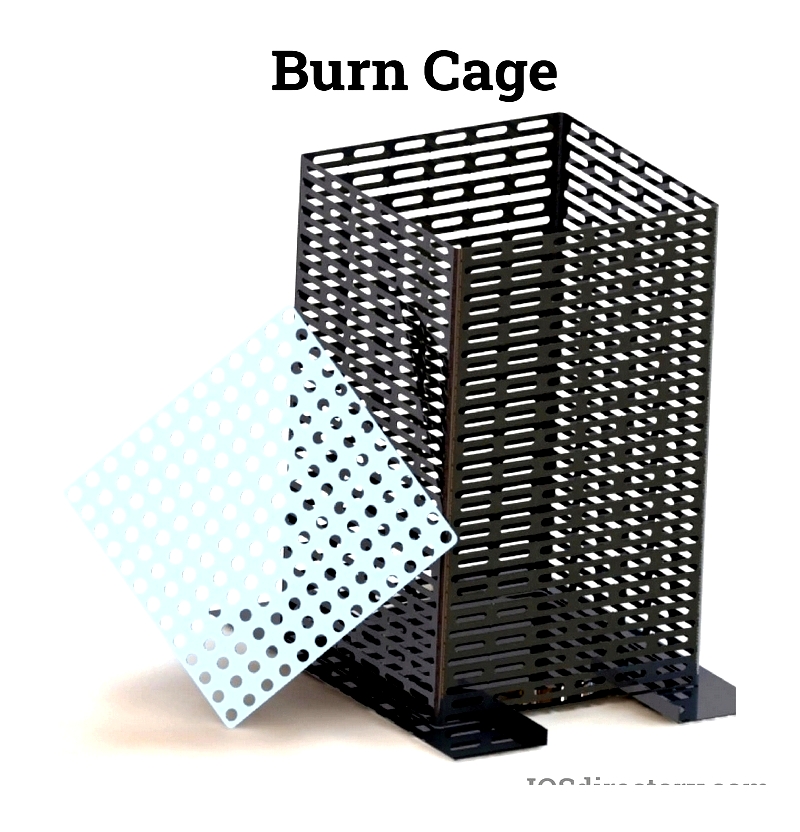

Burn Cage Incinerators

These open-frame designs maximize airflow for efficient burning while containing ash and embers. Ideal for large-scale or frequent use, they're often used in agricultural or commercial settings.

Many feature reinforced construction and carrying handles for durability and portability.

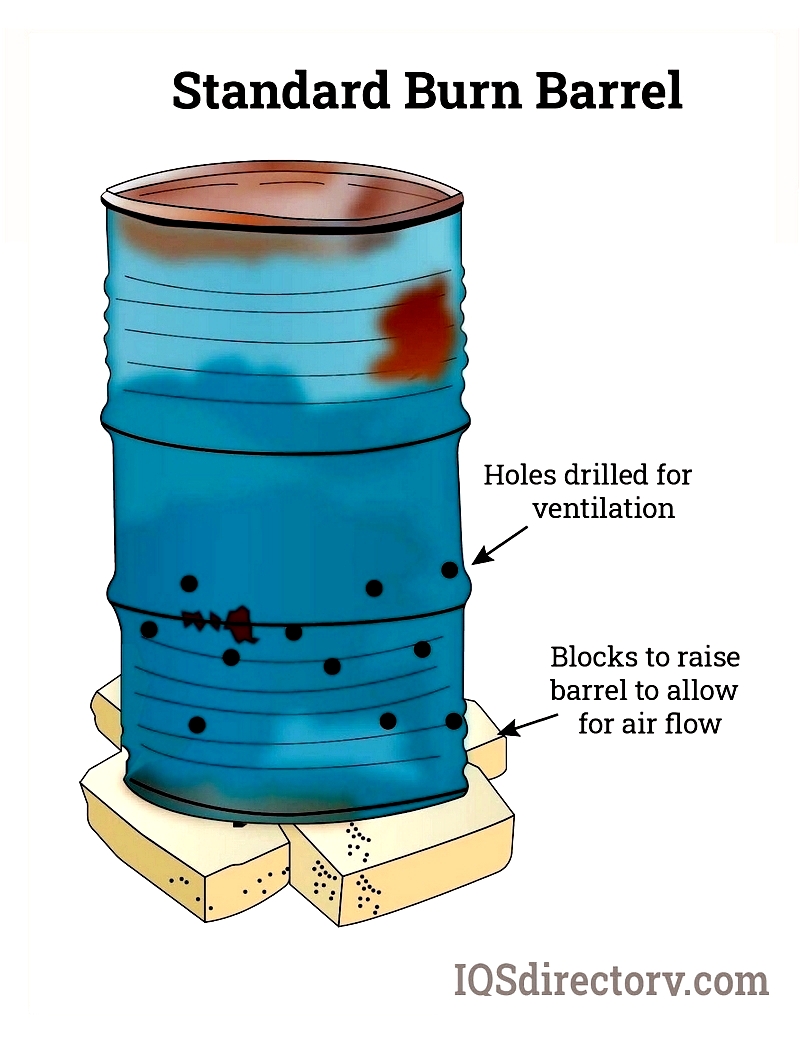

Traditional Burn Barrels

The original 55-gallon drum design remains popular in rural areas. Proper setup includes ventilation holes and stable platforms to prevent ground overheating.

Prefabricated models often include safety features like spark arrestors and ash cleanout doors for better compliance with regulations.

Choosing the Right Burn Barrel

Consider your waste volume, materials, and local regulations when selecting a barrel. Prioritize safety features like secure lids and proper ventilation to ensure safe, compliant operation.

Understanding your options helps you choose a barrel that meets your needs while promoting environmental responsibility.