Introduction

This article explains silicone rubber molding, its products, and their applications.

You will learn about:

- Silicone Rubber Molding basics

- Silicone Rubber Molding processes

- Silicone Rubber Mold types

- Materials used in Silicone Rubber Molding

- Advantages of Silicone Rubber Molding

- And more...

Chapter One: What is Silicone Rubber Molding?

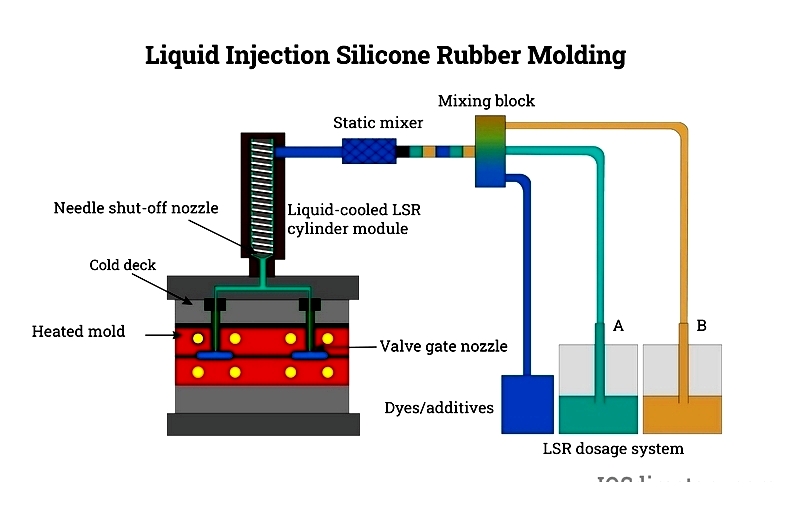

Silicone rubber molding is a manufacturing process that creates silicone components using heated molds. The process involves compressing or injecting silicone rubber into a mold cavity. Common techniques include injection molding, compression molding, and transfer molding, typically using steel or cast iron molds.

Silicone rubber comes in various hardness and flexibility levels, making it ideal for durable applications requiring temperature resistance. It can withstand temperatures above 100°C (212°F), making it suitable for medical instruments and engine seals.

Chapter Two: Silicone Rubber Types

Originally developed for electrical insulation, silicone rubber's flexibility and chemical resistance expanded its use across industries. Choosing the right type enhances product efficiency and durability. Its heat resistance and electrical properties come from its silicon-oxygen structure.

Unlike organic elastomers, silicone rubber features alternating silicon and oxygen atoms, providing temperature resistance and flexibility. Although discovered in the 1800s, it became commercially significant in the mid-20th century.

Initially, silicone rubber addressed the need for heat-resistant insulation in electric motors. Researchers developed it to withstand high temperatures and electrical stress, leading to applications in medical devices, seals, and electrical components.

Silicone Rubber Classifications

Silicone rubber is classified using the Shore hardness scale, which measures resistance to deformation. The scale ranges from 0 (soft) to 100 (hard), with different scales (Shore A, D, 00) for various materials.

By adjusting fillers and additives, silicone rubber's properties can be tailored for specific applications, enhancing performance in challenging environments.

General Purpose Silicone Rubber

With a Shore hardness of A 30 to A 70, this type is used in kitchenware, medical hoses, and automotive parts. Food-safe variants meet FDA standards.

Low Hardness Silicone Rubber

Shore hardness A 5 to A 20 makes this type ideal for baby products, anti-slip mats, and wearable items due to its elasticity and cushioning.

High Hardness Silicone Rubber

With Shore hardness up to A 90, this type offers excellent tear strength for industrial seals and engine mounts.

High Strength Silicone Rubber

This type resists abrasion and mechanical stress, with tear strength up to 49 kN/m, making it suitable for heavy-duty applications.

Transparent Silicone Rubber

Used in medical and optical applications, this type has a Shore hardness of A 10 to A 70 and allows visual inspection.

Flame Retardant Silicone Rubber

Engineered for fire resistance, this type meets UL 94 V-0 standards and is used in aerospace and electrical enclosures.

Thermal Conductive Silicone Rubber

This type dissipates heat in electronics, making it ideal for CPUs and LED lighting.

Electrically Conductive Silicone Rubber

Contains conductive fillers for EMI shielding in electronics and aerospace applications.

Heat Resistant Silicone Rubber

Withstands temperatures up to 300°C (572°F), suitable for oven seals and engine gaskets.

Oil Resistant Silicone Rubber

Resists hydraulic fluids and lubricants, ideal for automotive and industrial seals.

Fluorosilicone Rubber

Combines chemical resistance with thermal stability, used in aerospace and military applications.

Silicone Rubber Organic Groups

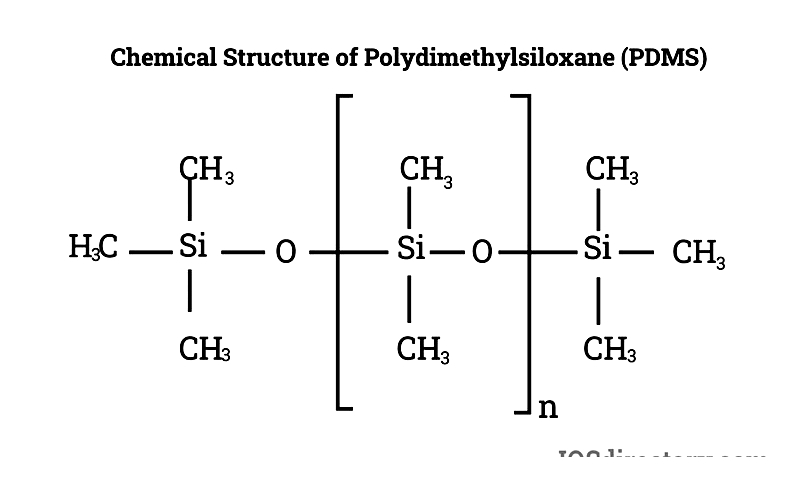

Organic groups like methyl, vinyl, and fluorine determine silicone rubber's properties. These groups influence flexibility, curing, and chemical resistance.

- Methyl Group – Basic insulation and general-purpose sealing.

- Methyl and Phenyl Groups – Enhanced cold resistance.

- Methyl and Vinyl Groups – Faster curing and improved strength.

- Methyl, Phenyl, and Vinyl Groups – Low-temperature flexibility.

- Fluorine, Vinyl, and Methyl Groups – Superior chemical resistance.

Selecting the right silicone rubber type ensures optimal performance for specific applications.

Chapter Three: Silicone Rubber Production

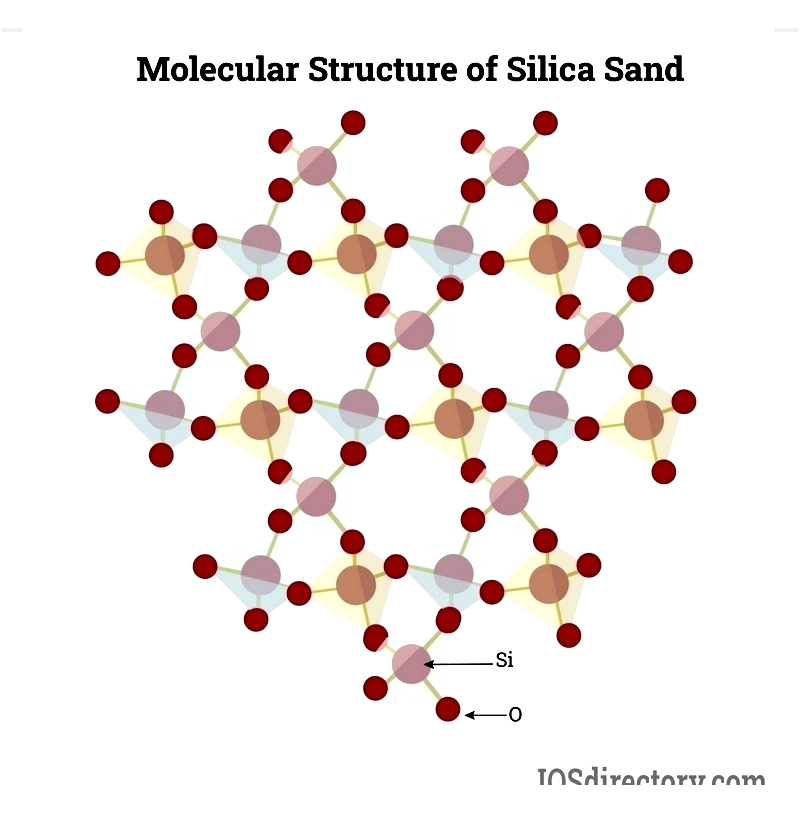

Silicone rubber's silicon-oxygen backbone provides flexibility and thermal stability. It starts with isolating silicon from silica sand at high temperatures.

Isolating Silicon from Silica

Quartz sand is heated to 1800°C (3272°F) to produce silicon, which is then reacted with methyl chloride to form the silicone base.

Compounding

Cross-linking PDMS chains creates a durable network. Additives tailor properties for specific applications.

Final Form

Fillers and additives enhance properties like strength and conductivity. Common additives include:

- Crosslinking Agents – Improve mechanical stability.

- Fillers – Increase strength and conductivity.

- Stabilizers – Protect against thermal degradation.

- Flame Retardants – Enhance fire resistance.

- Pigments – Provide color options.

Vulcanization

Curing solidifies silicone rubber through cross-linking. Methods include:

HTV (High Temperature Vulcanization): For high-strength applications.

RTV (Room Temperature Vulcanization): For flexible products like sealants.

Chapter Four: Silicone Rubber Mold Uses

Silicone molds are durable and reusable, ideal for prototyping and short production runs. They withstand temperature changes and chemical exposure.