Introduction

This article provides a detailed discussion on wire electrical discharge machining (EDM).

After reading, you should understand:

- What Wire EDM is and how it works

- Key considerations in Wire EDM

- Components of a Wire EDM machine and wire selection

- The Wire EDM process

- Differences between Wire EDM and conventional EDM

- Leading Wire EDM machine manufacturers

- Applications, advantages, and disadvantages of Wire EDM

- And more...

Chapter One: Understanding Wire EDM and Its Mechanism

Defining Wire EDM

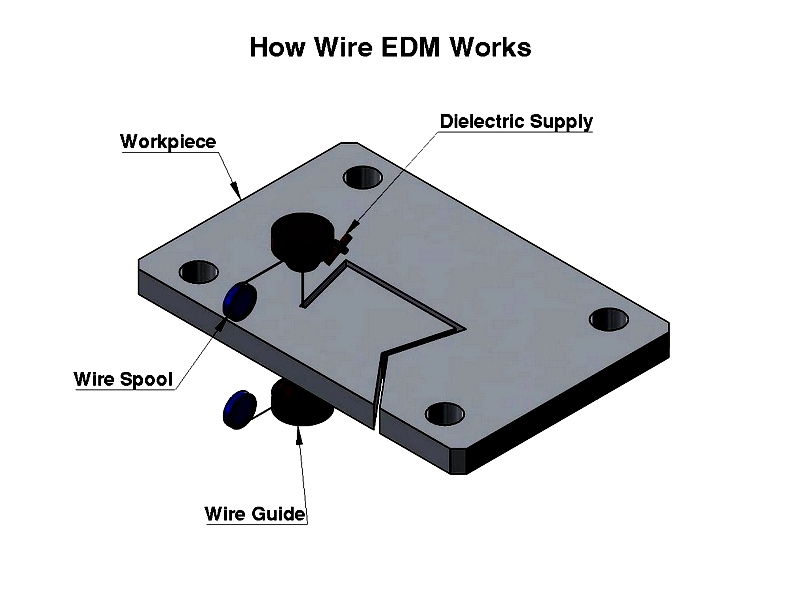

Electrical discharge machining (EDM) is a high-precision process that uses thermal energy rather than mechanical force to remove material. Wire EDM, a specialized EDM form, employs a fine metal wire (typically brass or copper) as the cutting electrode. This method utilizes deionized water, which conducts electricity while preventing rust. The thin wire electrode moves along a preset path to cut or shape the workpiece. Wire diameters typically range from 0.004 to 0.012 inches (0.10mm to 0.30mm), with the wire continuously fed from spools to maintain an unworn cutting section.

Wire EDM effectively machines parts resistant to traditional processes, provided they're electrically conductive. Common materials include steel, titanium, super alloys, and brass. The process creates small chips through melting or vaporizing material rather than cutting. This versatility makes EDM widely useful for handling strong metals efficiently.

Wire EDM is valued for efficiently machining conductive, challenging materials with precision. It enables complex designs with tight tolerances while being ideal for hard, brittle, or delicate materials as a non-contact method.

How Wire EDM Works

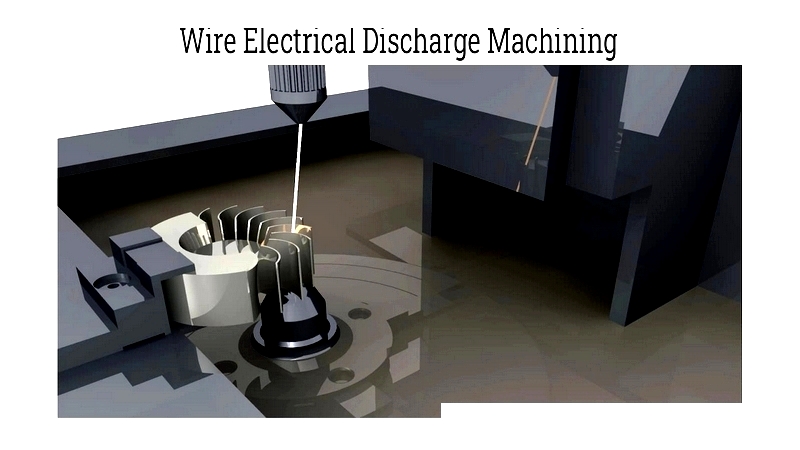

Wire EDM precisely cuts, trims, and removes material. An electrical discharge between the wire electrode and workpiece creates sparks that remove material from both. The process uses a dielectric fluid to prevent shorting and remove debris.

Machining begins with a starting hole or edge cut. Each discharge creates a tiny crater while marking the electrode. The wire's angling capability allows tapered profiles. The electrode and workpiece never touch physically. Depending on requirements, the workpiece may undergo cutting, roughing, and skimming passes. Typically, the wire cuts through material completely before removing scrap pieces, with a final skim pass often ensuring optimal accuracy.

Voltage pulses create electron flow between electrode and workpiece, affecting deionized water molecules. Accumulating ions and electrons form current, with temperatures reaching nearly 10,000°C, melting and vaporizing material. The dielectric fluid then removes molten material.

Precision depends on cutting parameters and speed. Higher speeds may bend the wire slightly, affecting accuracy. Maximum precision requires lower power and speed settings, achieving tolerances of +/- 0.0002 inches, while higher speeds typically yield +/- 0.001 inch tolerances.

Chapter Two: Key Considerations in Wire EDM

EDM Wire Types and Sizes

EDM wire diameters range from 0.0008 to 0.013 inches, offering options for various applications. Smaller wires suit intricate, high-precision tasks requiring lower power and slower speeds. The 0.010-inch brass wire serves over 80% of applications as the industry standard. Other options include zinc-coated, coated, and molybdenum wires, each offering specific benefits like improved cutting speed or wear resistance. Selecting the appropriate wire for the material, thickness, and tolerances maximizes efficiency and surface quality while minimizing costs.

Part Geometry

Design geometry significantly impacts Wire EDM suitability. Complex features like sharp internal corners or thin walls require advanced CNC programming. While Wire EDM excels at tight tolerances and complex profiles, some designs present challenges like wire erosion or surface finish inconsistencies. Early evaluation during design helps ensure manufacturability and avoids costly redesigns.

Surface Finish and Tolerance Requirements

Surface finish and tolerance specifications should align with part function and industry standards. Wire EDM can achieve finishes as fine as 3 microinches (Ra), but unnecessary tight tolerances increase costs. Material choice and part height affect accuracy, with taller components requiring more material removal force. Post-processing like deburring may be necessary for specific surface requirements.

Material Thickness and Conductivity

Material selection significantly impacts machining performance. Common Wire EDM materials include tool steels, stainless steel, titanium, and conductive alloys. Conductivity, thickness, and hardness affect cutting speed and quality. Proper material choice can reduce costs while meeting hardness and tolerance requirements.

Time Considerations

Wire EDM typically has slower cutting rates than conventional CNC processes. Complex geometries or demanding finishes extend production time. Early consultation with service providers helps optimize scheduling and maintain quality.

Programming Requirements

Precise CNC programming is essential for successful Wire EDM. CAD/CAM software helps develop wire paths and predict potential issues. Program verification prevents errors before cutting begins, with operator-designer collaboration ensuring machining strategy alignment.

Additional Factors: Cost, Quality, and Vendor Selection

Choosing the right Wire EDM partner involves evaluating experience, certifications, quality assurance, and project handling capabilities. Sample parts and testimonials help assess potential vendors. Clear communication ensures projects meet budget and timeline requirements.